HJ Smartlube 4.0

Please select a hotspot to learn more.

HJL360 » HJ Smartlube 4.0 Overview » HJ Smartlube 4.0

HJ SMARTLUBE 4.0

QUICK FACTS

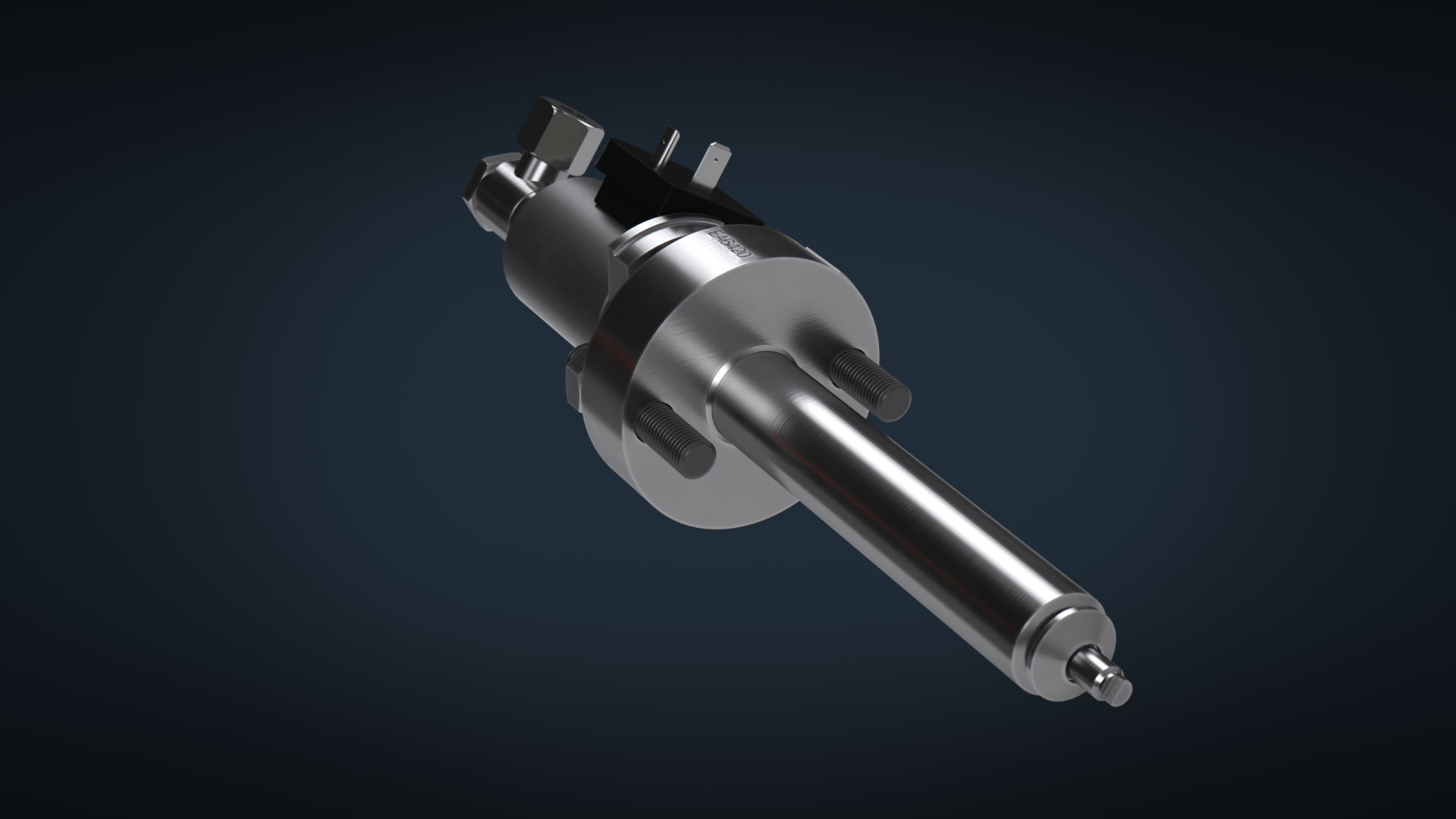

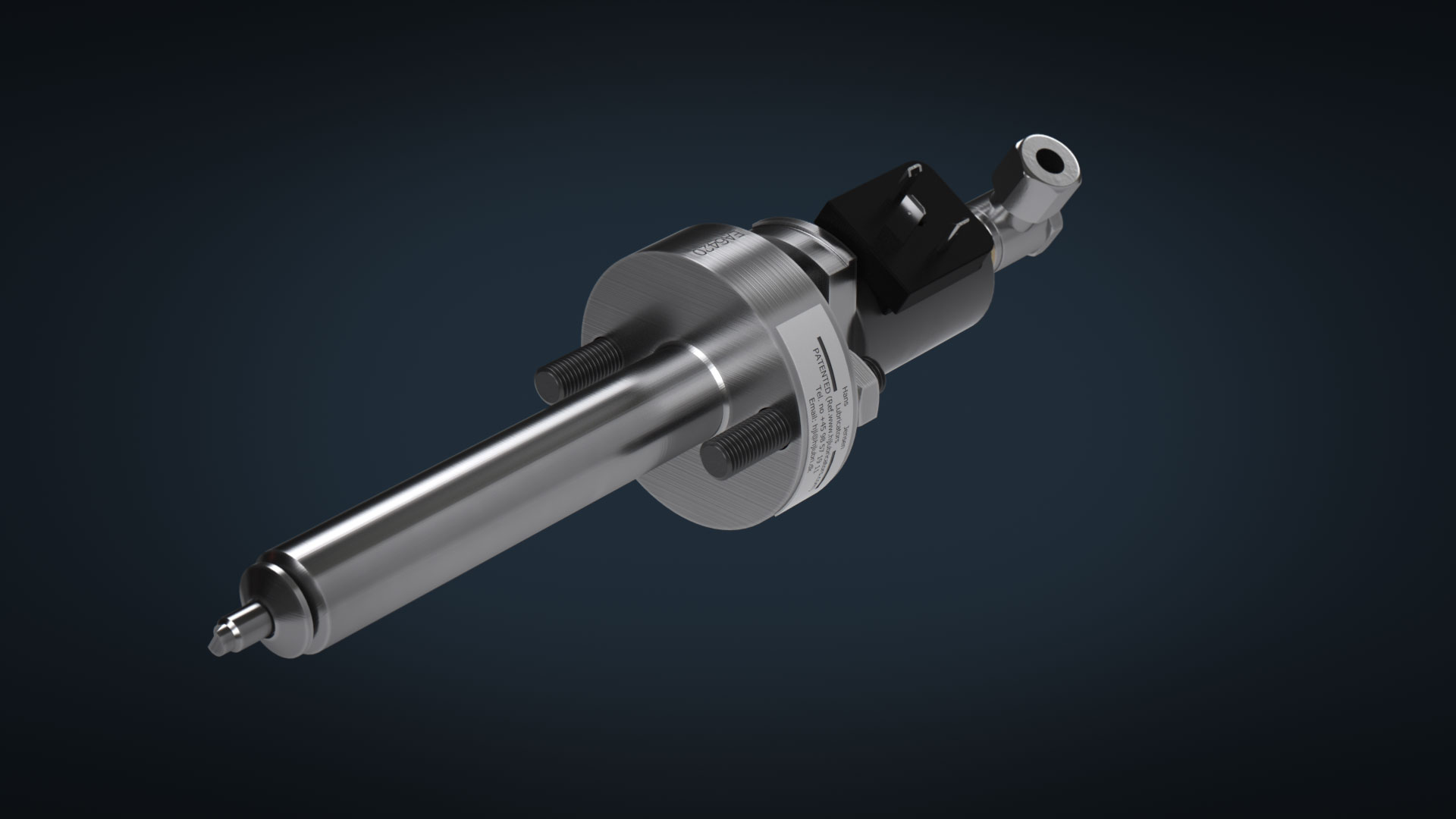

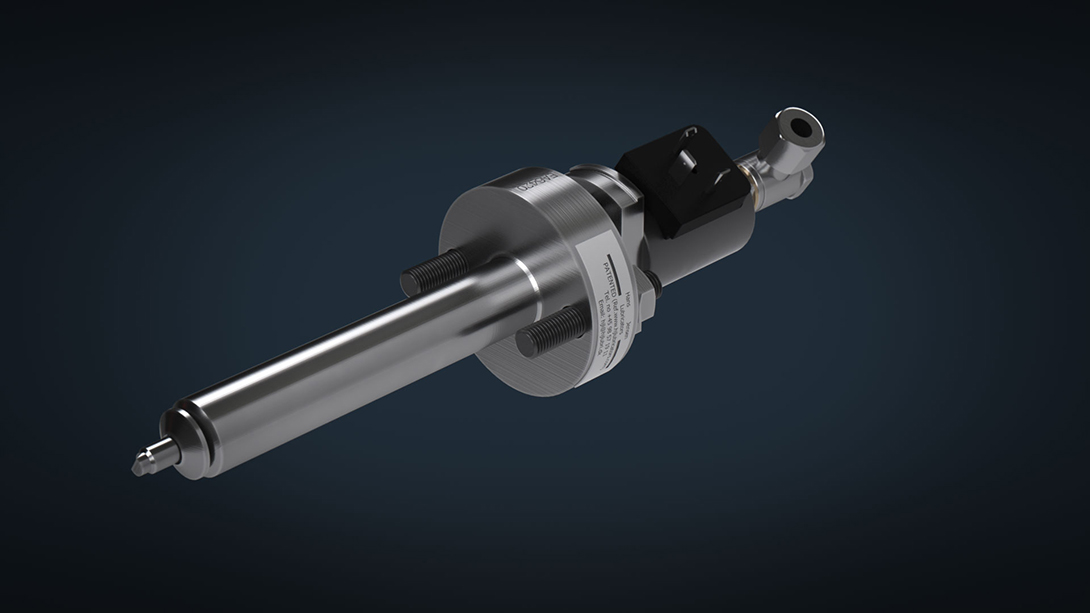

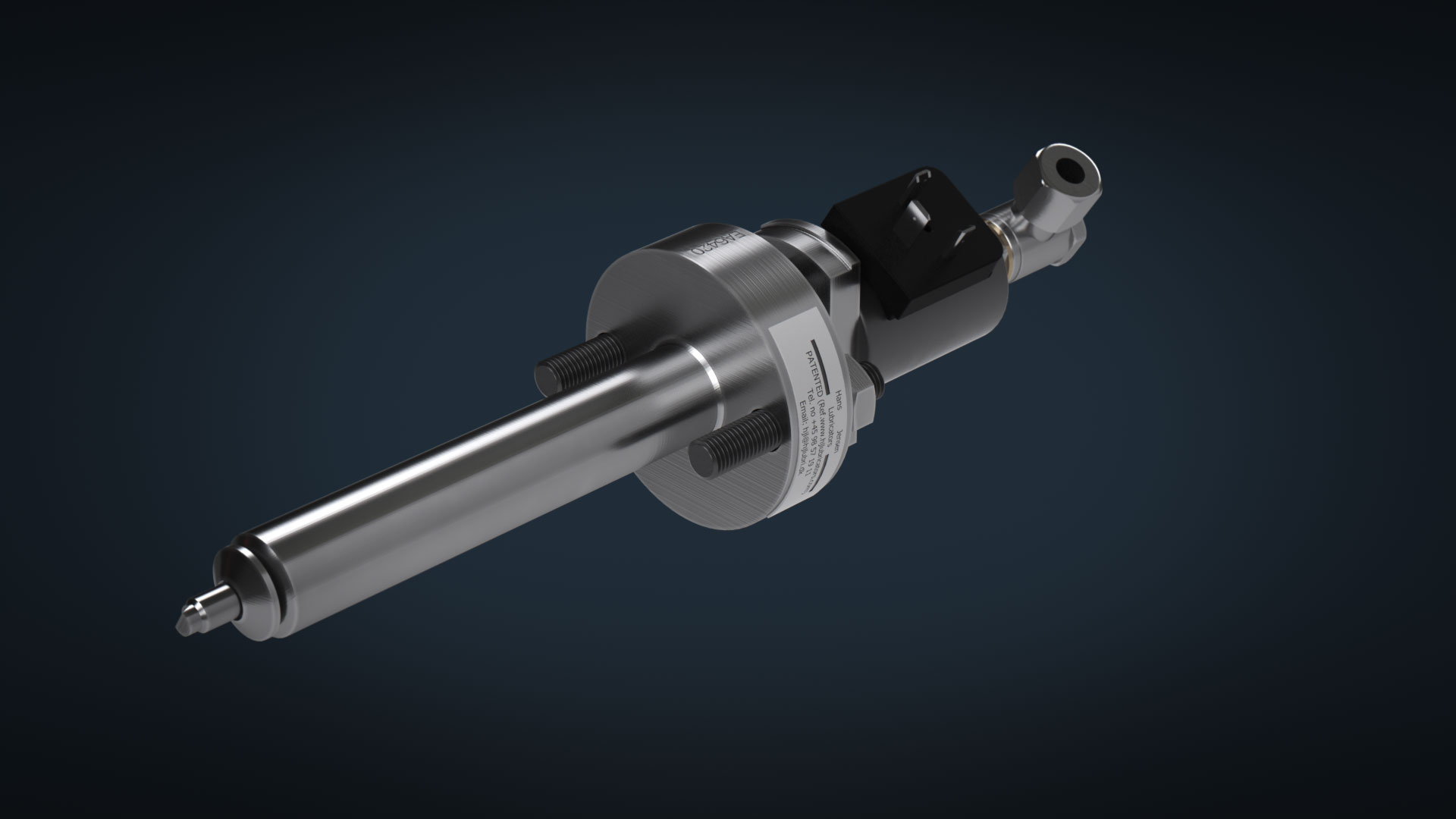

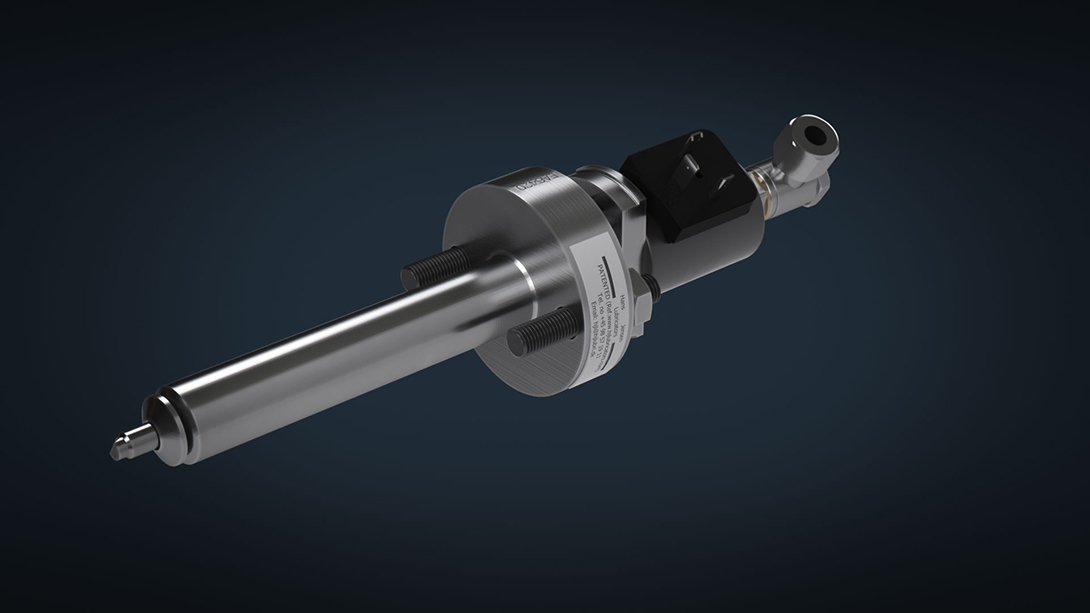

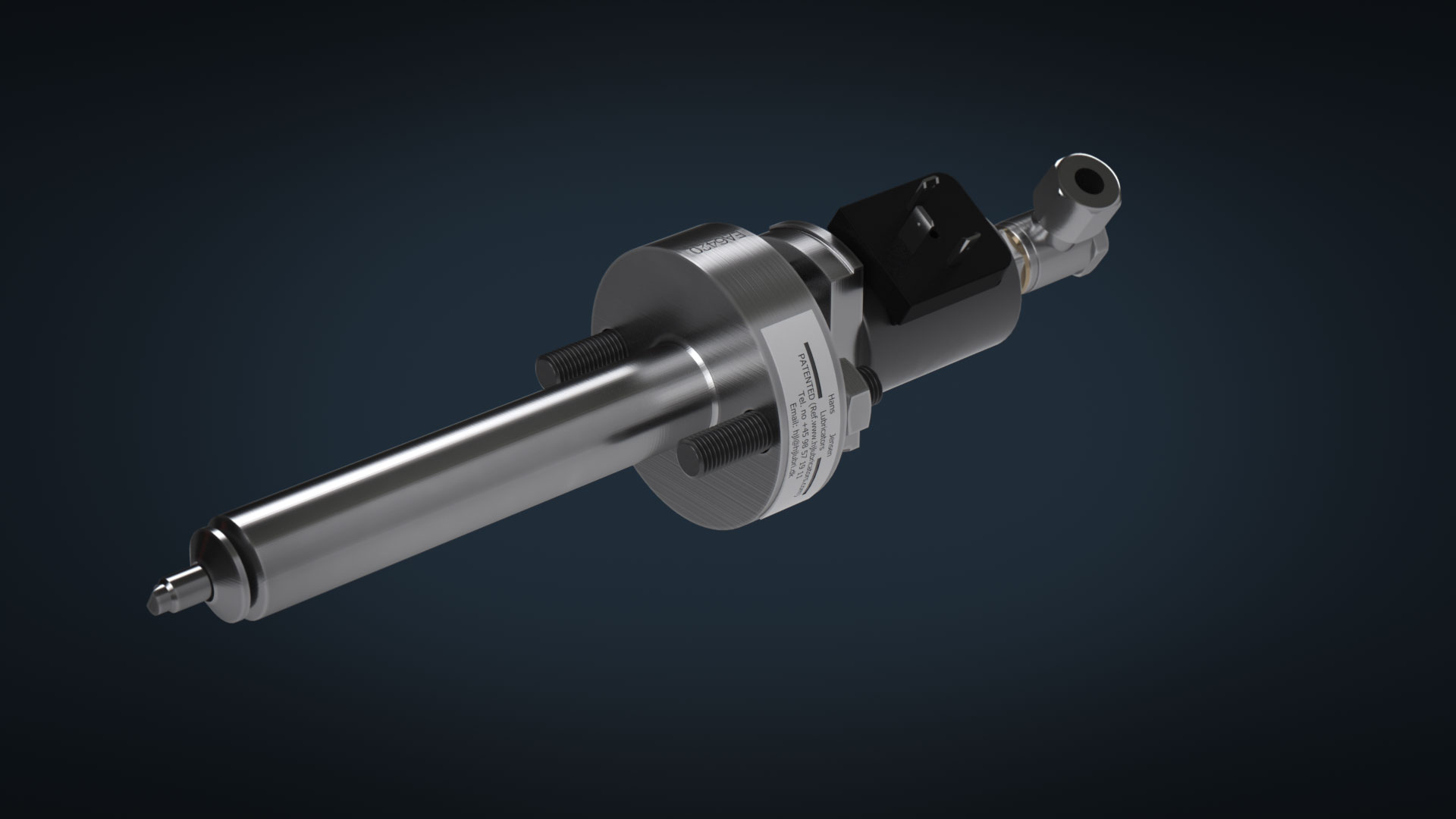

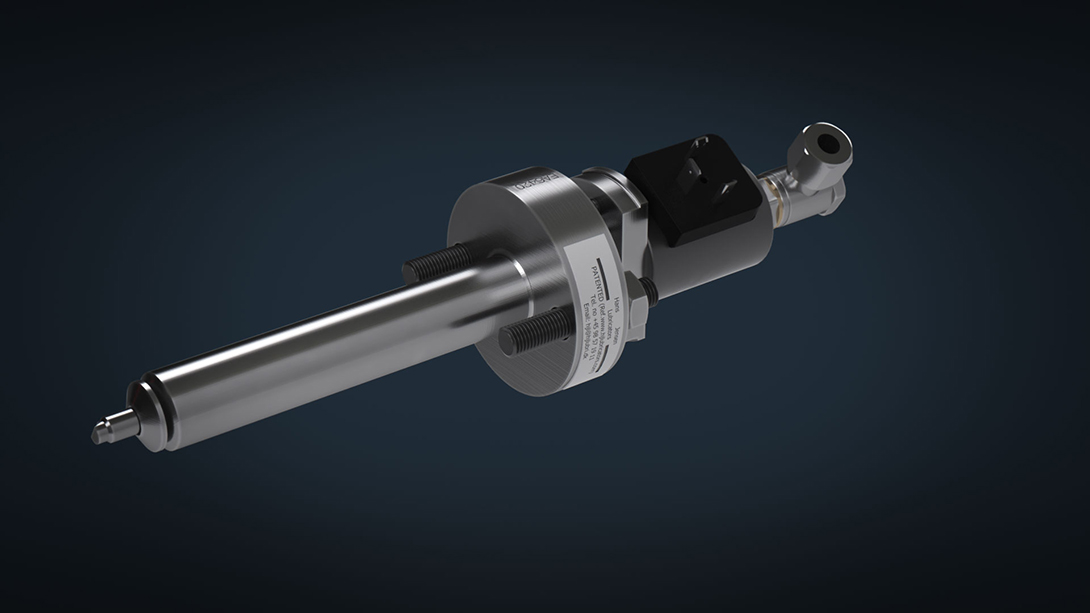

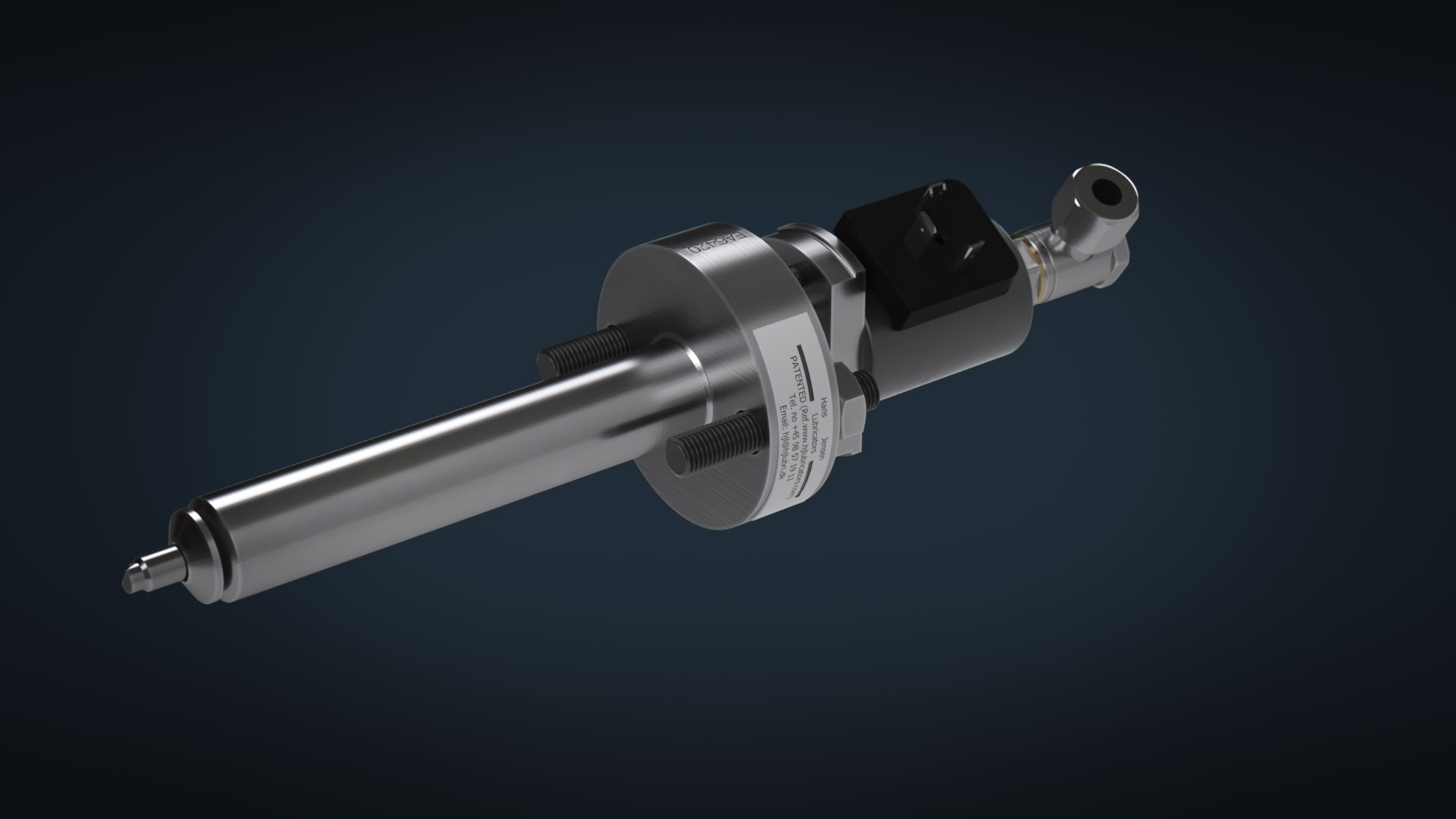

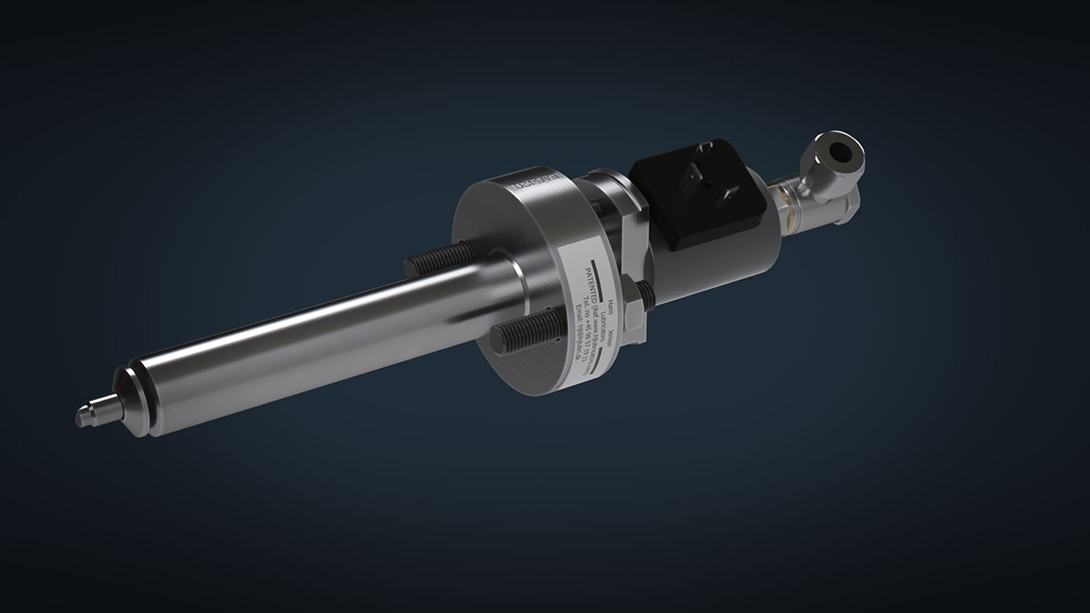

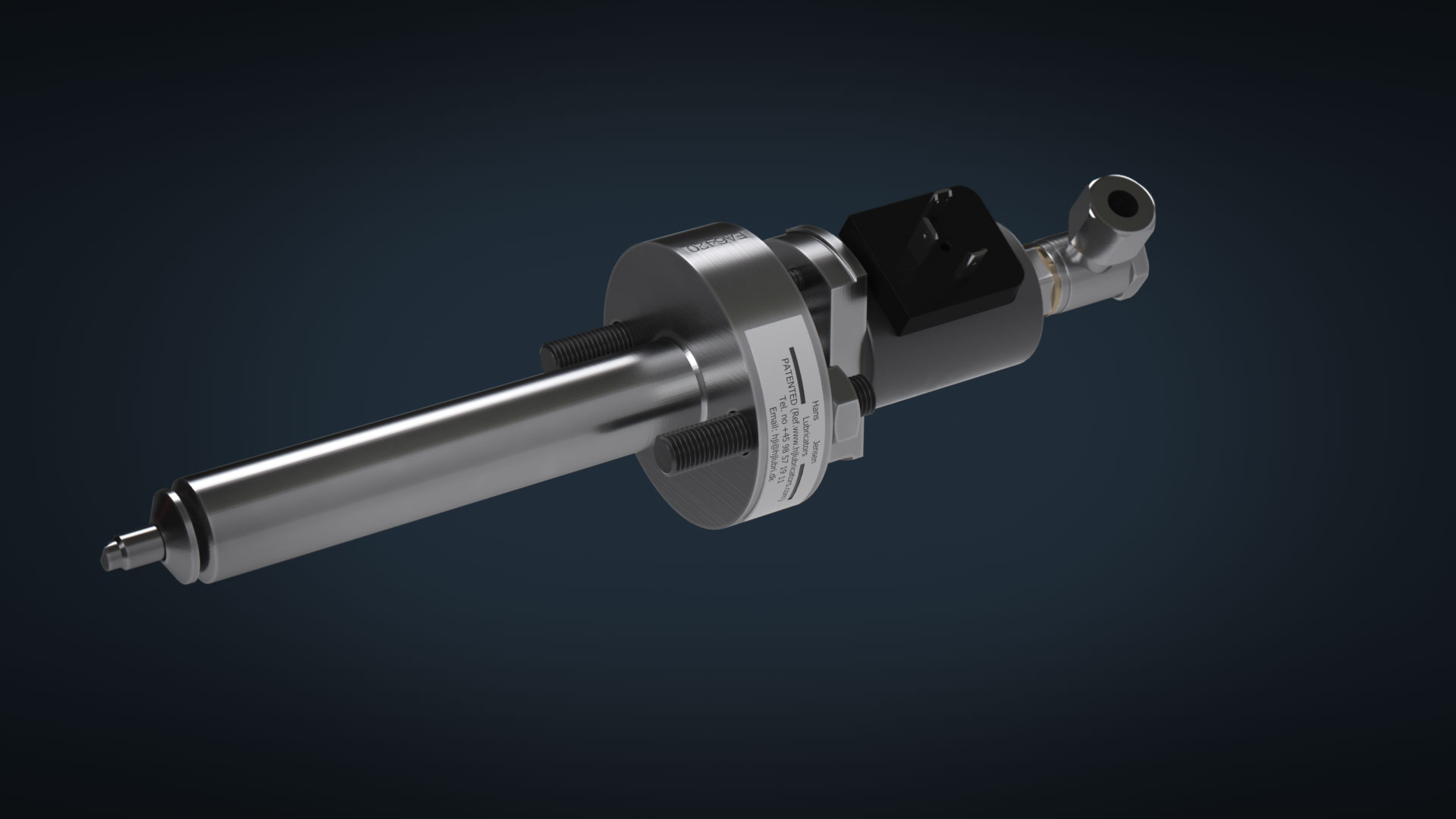

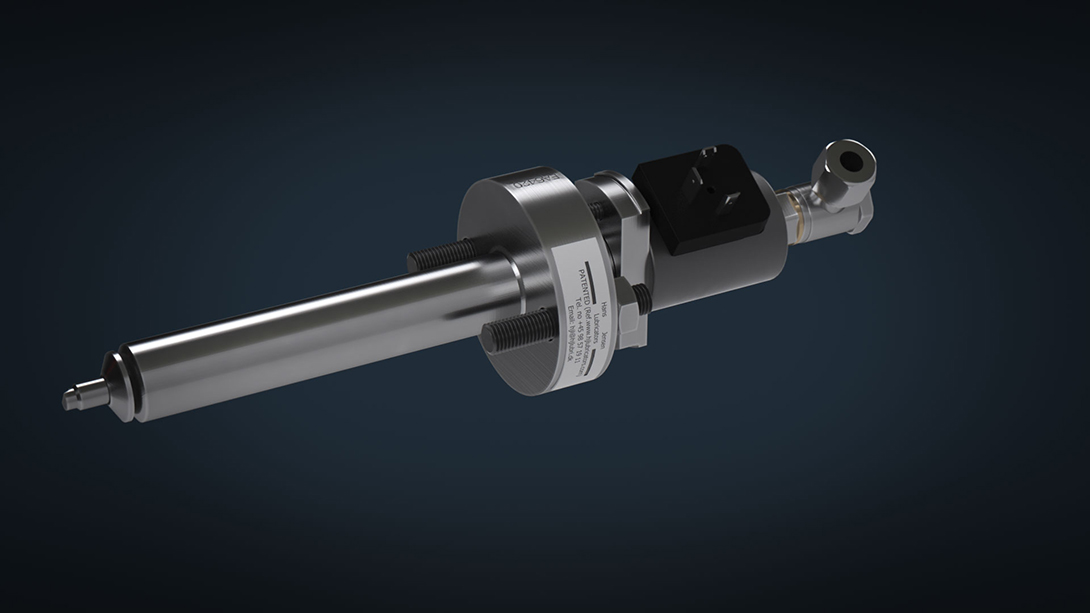

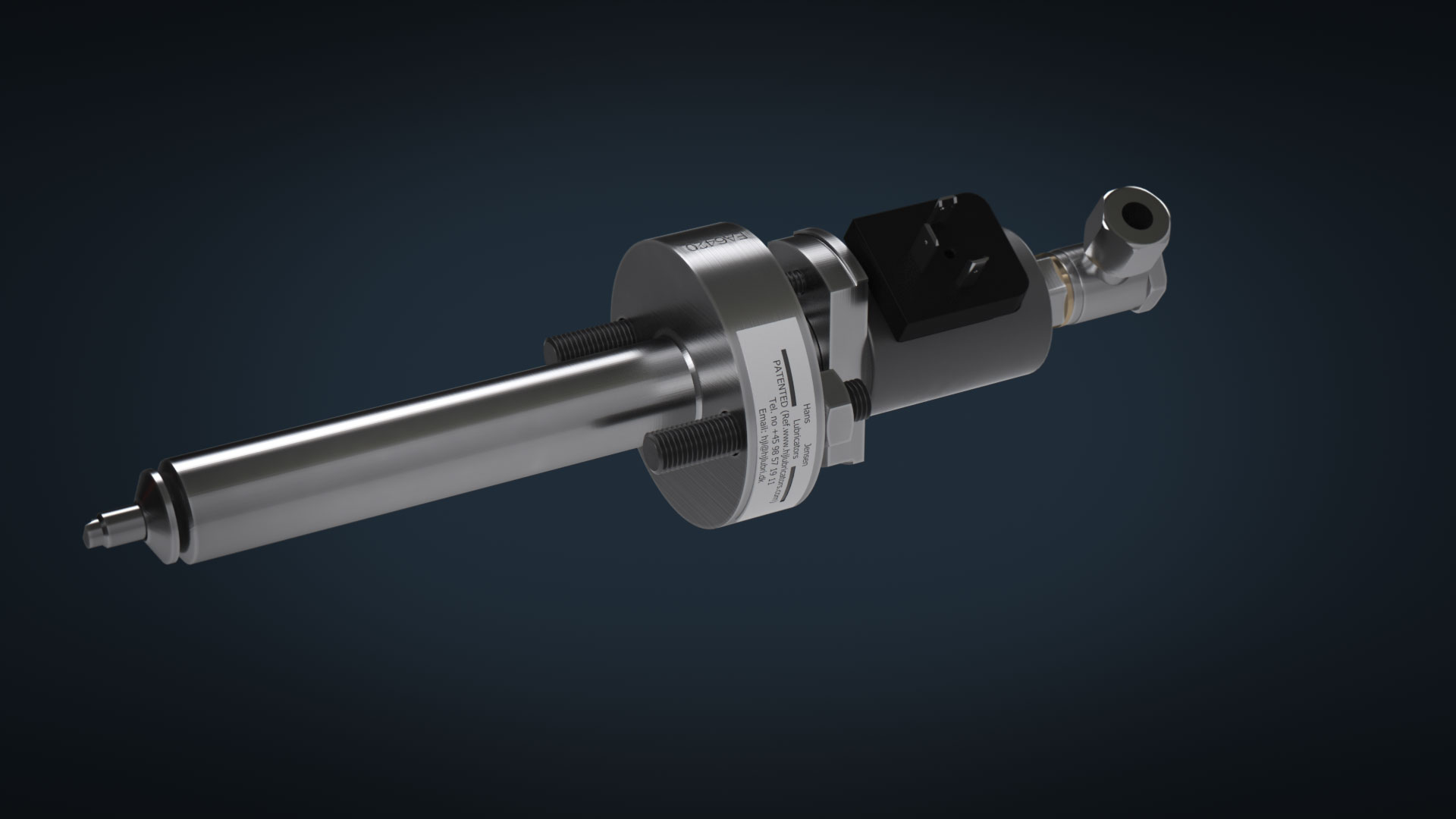

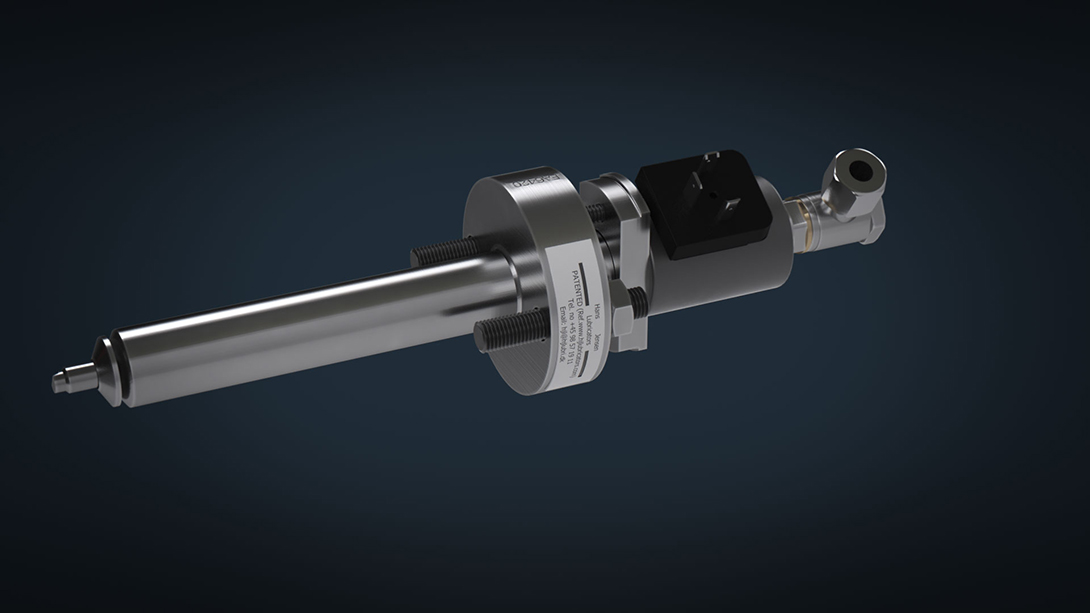

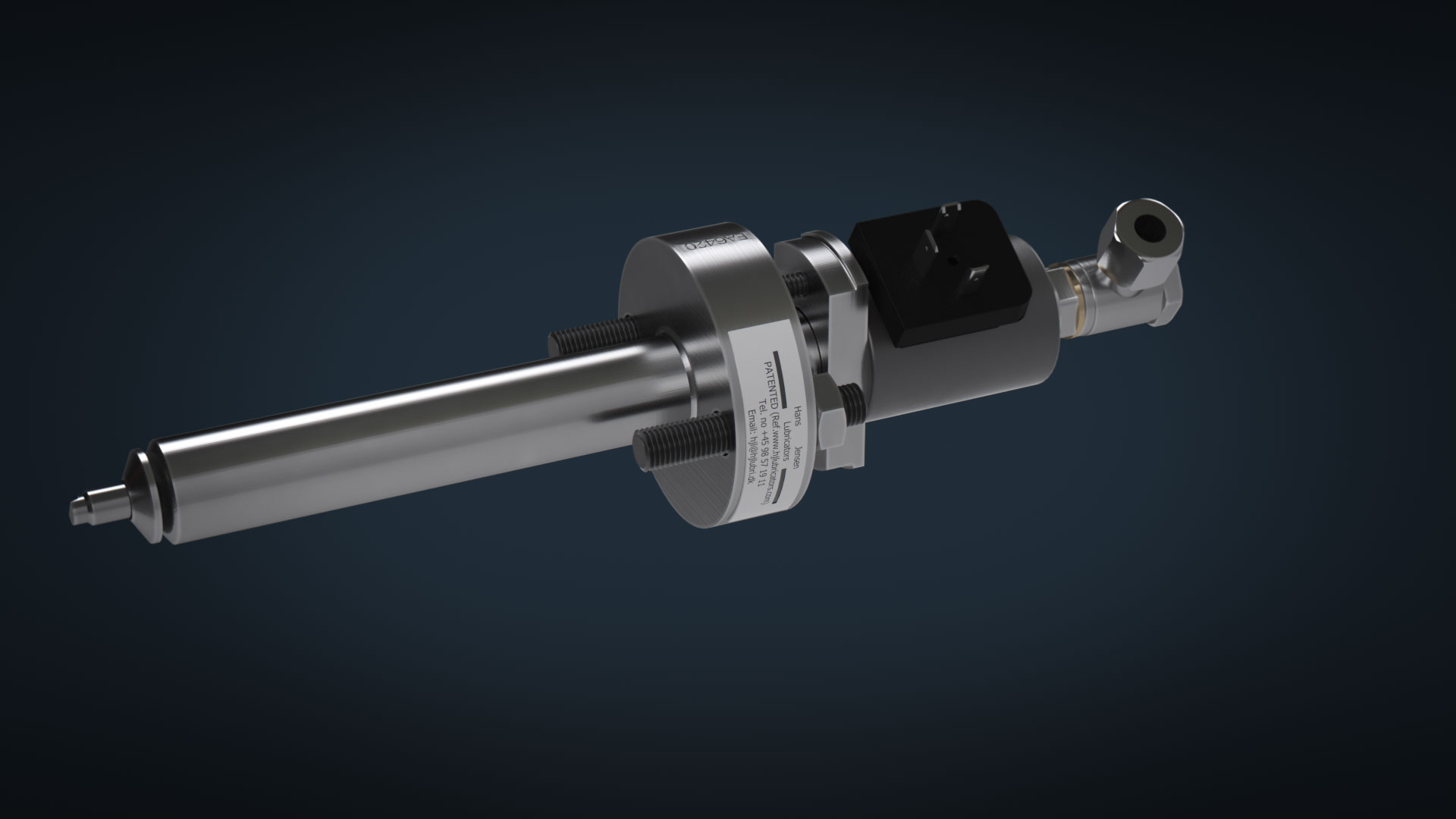

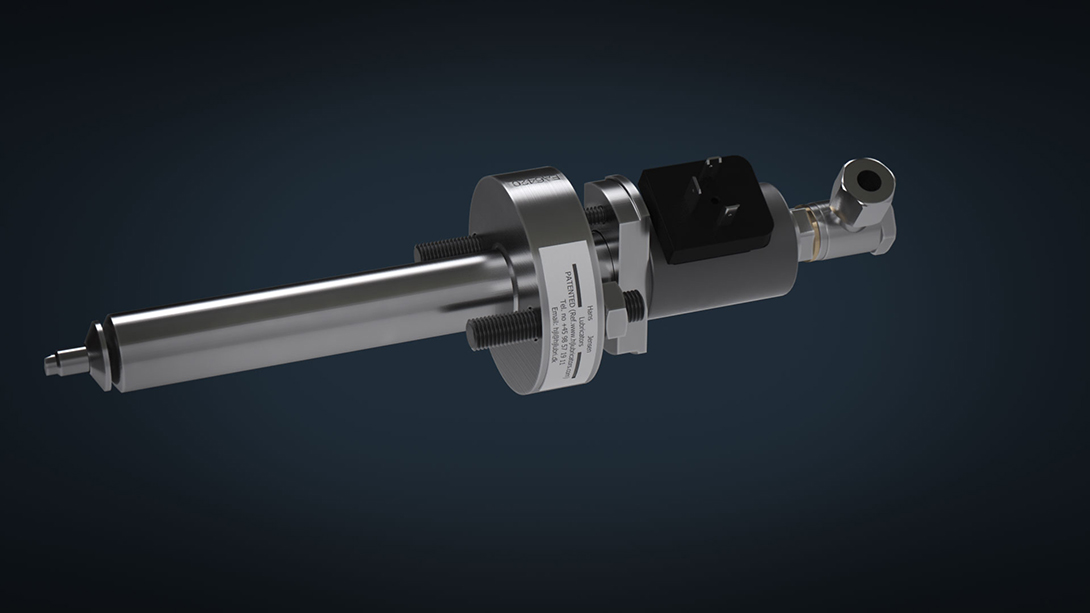

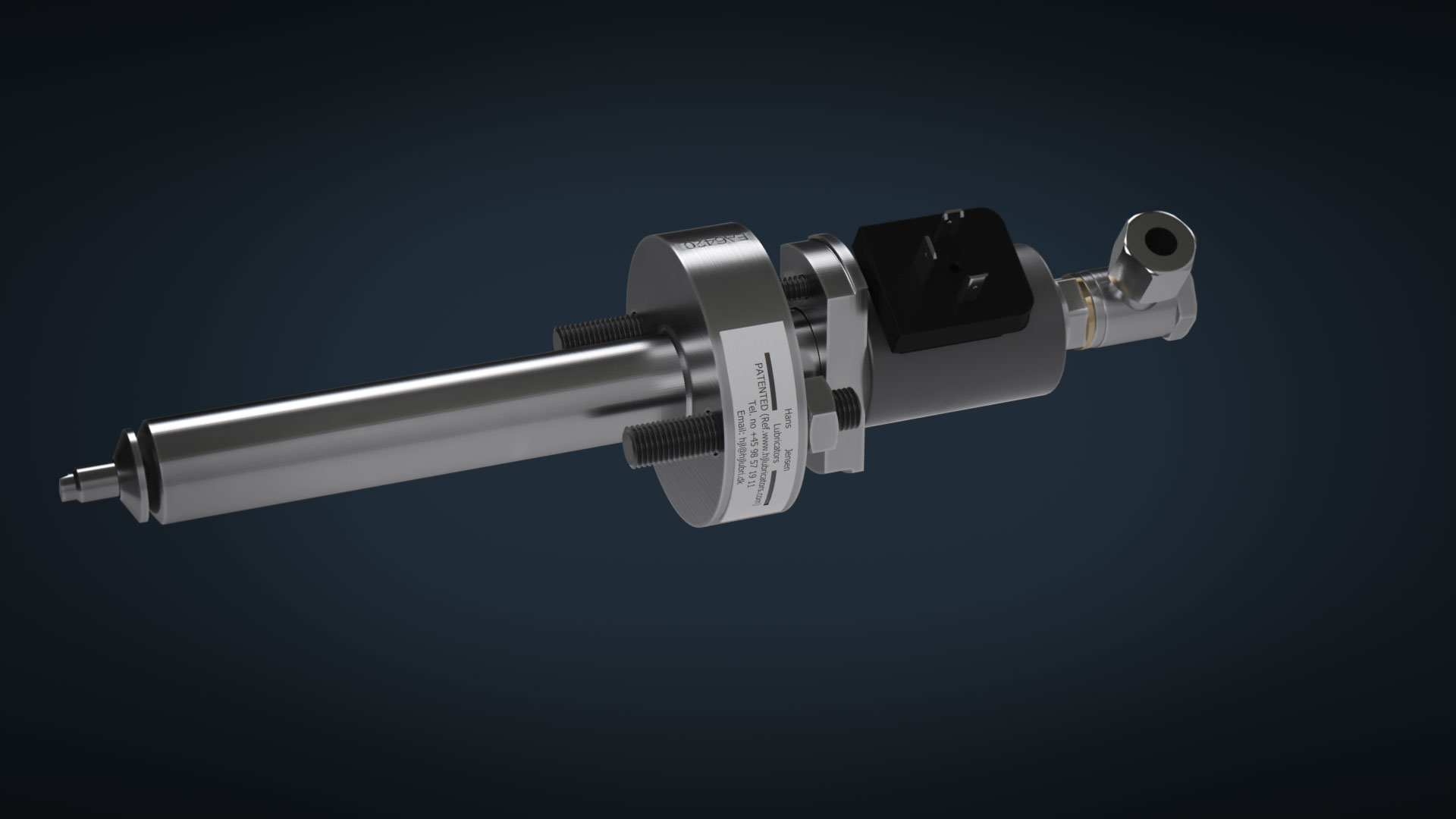

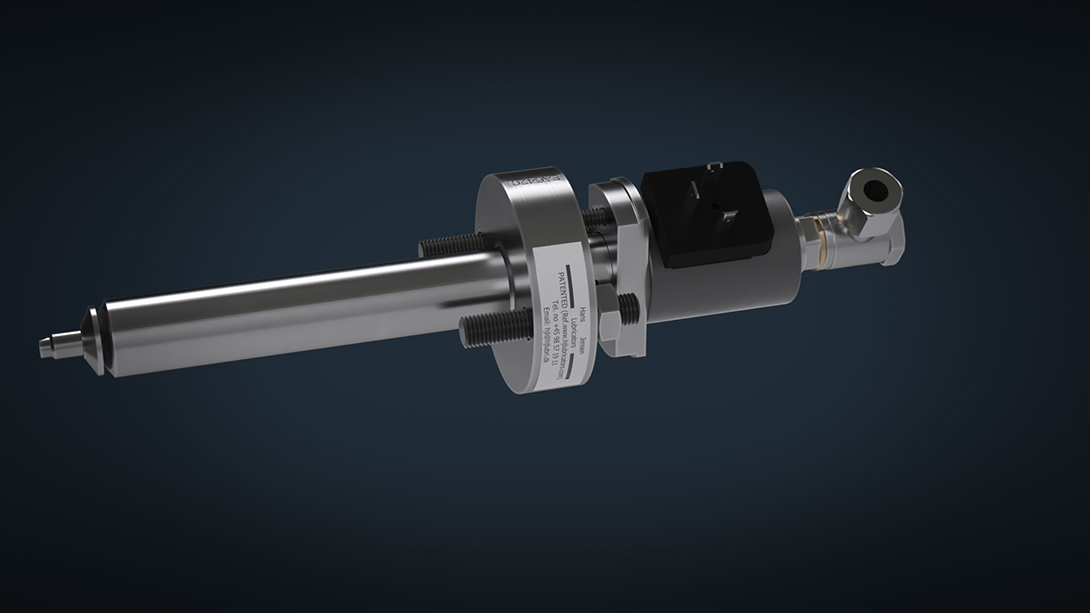

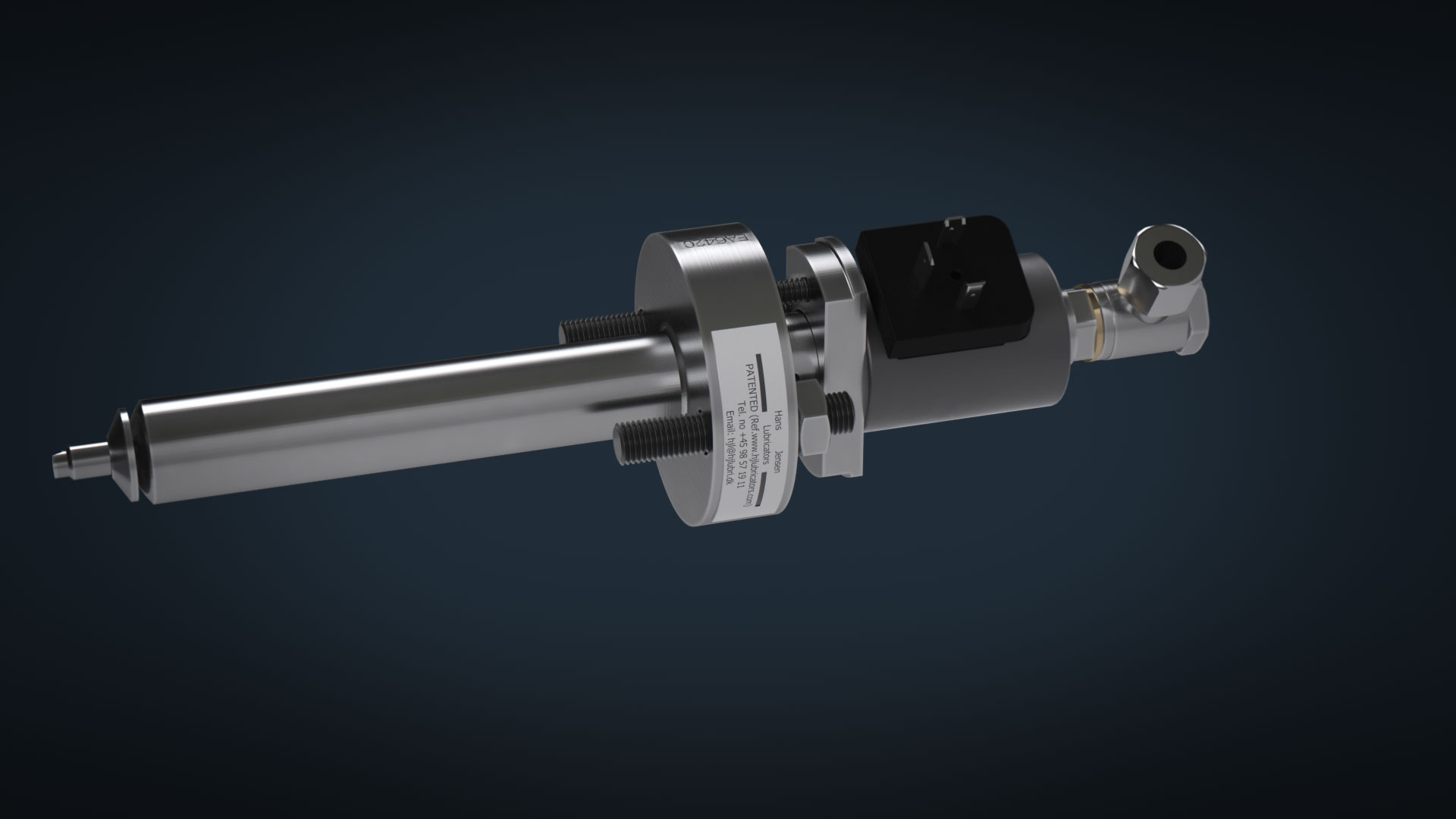

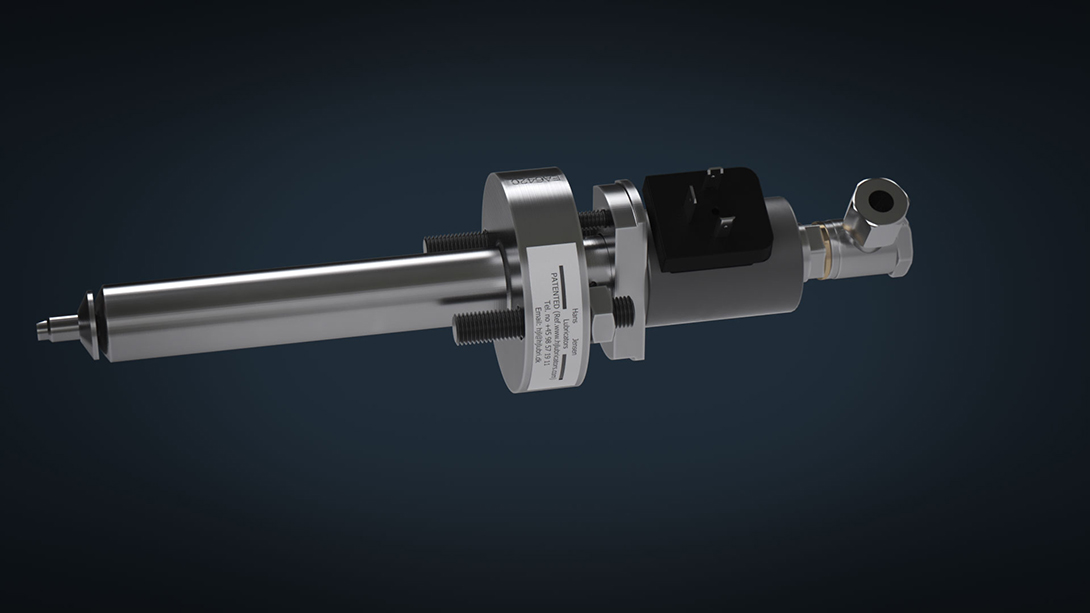

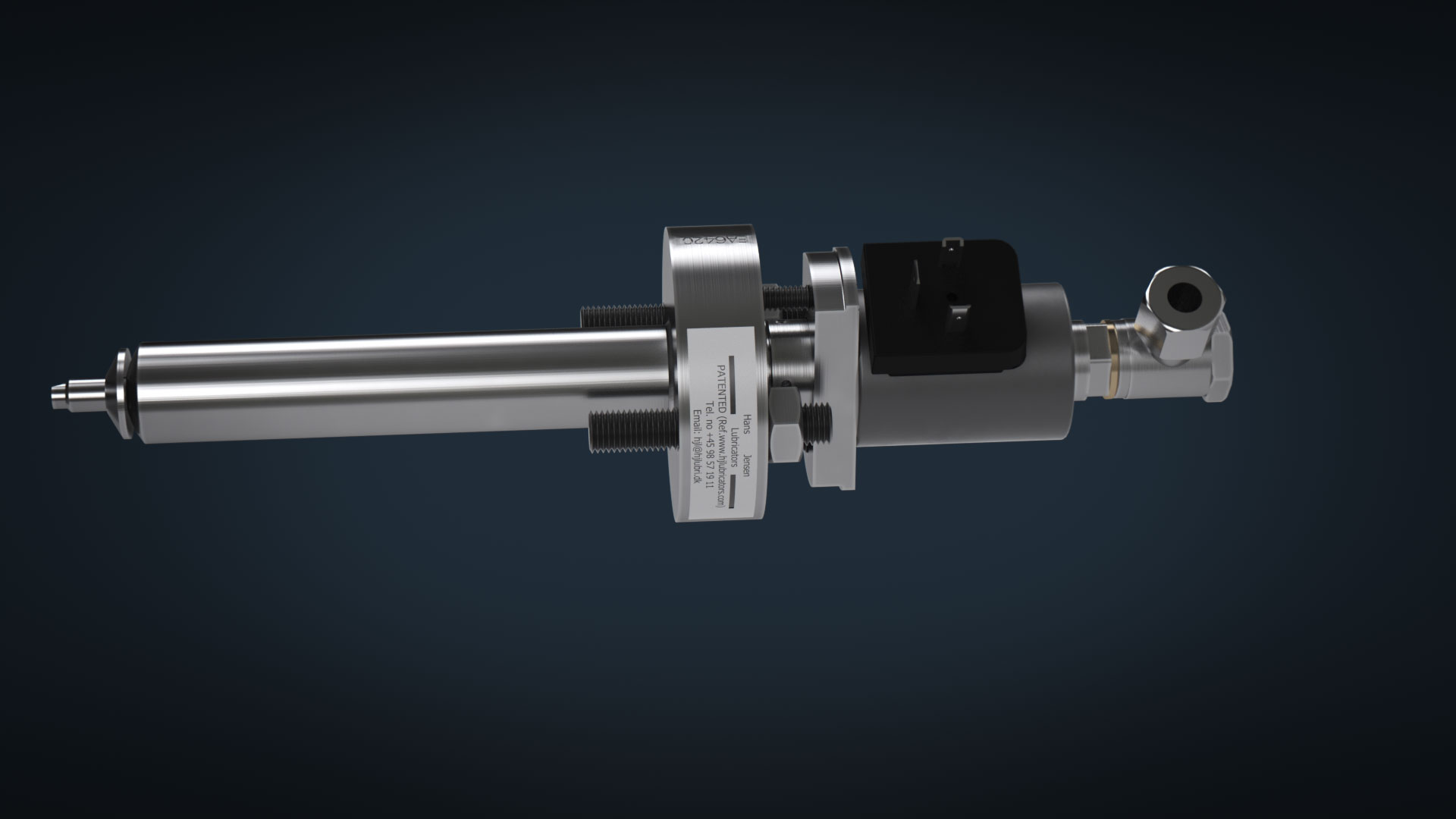

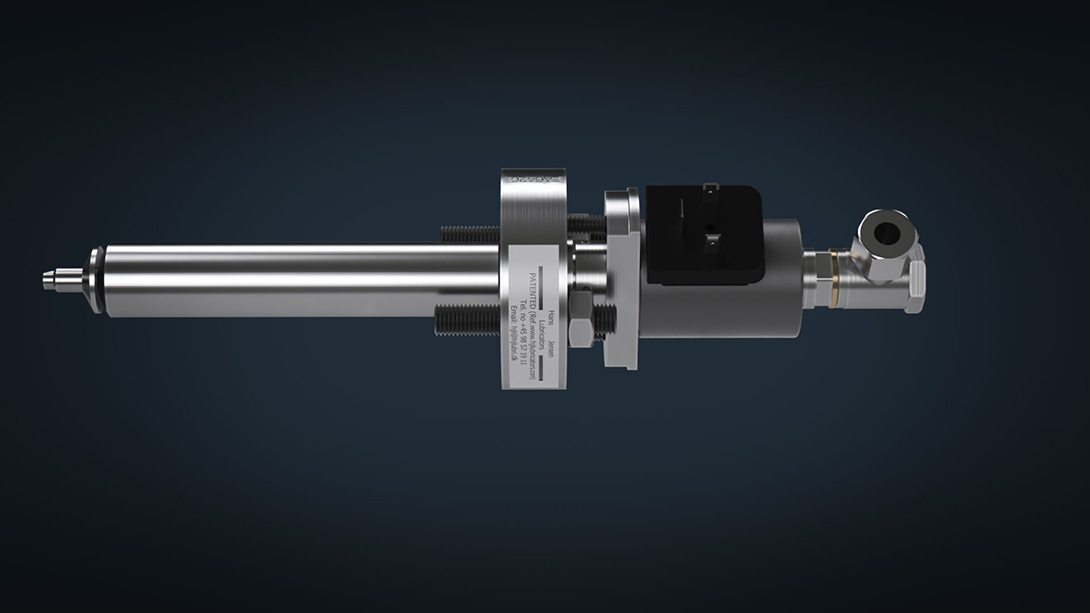

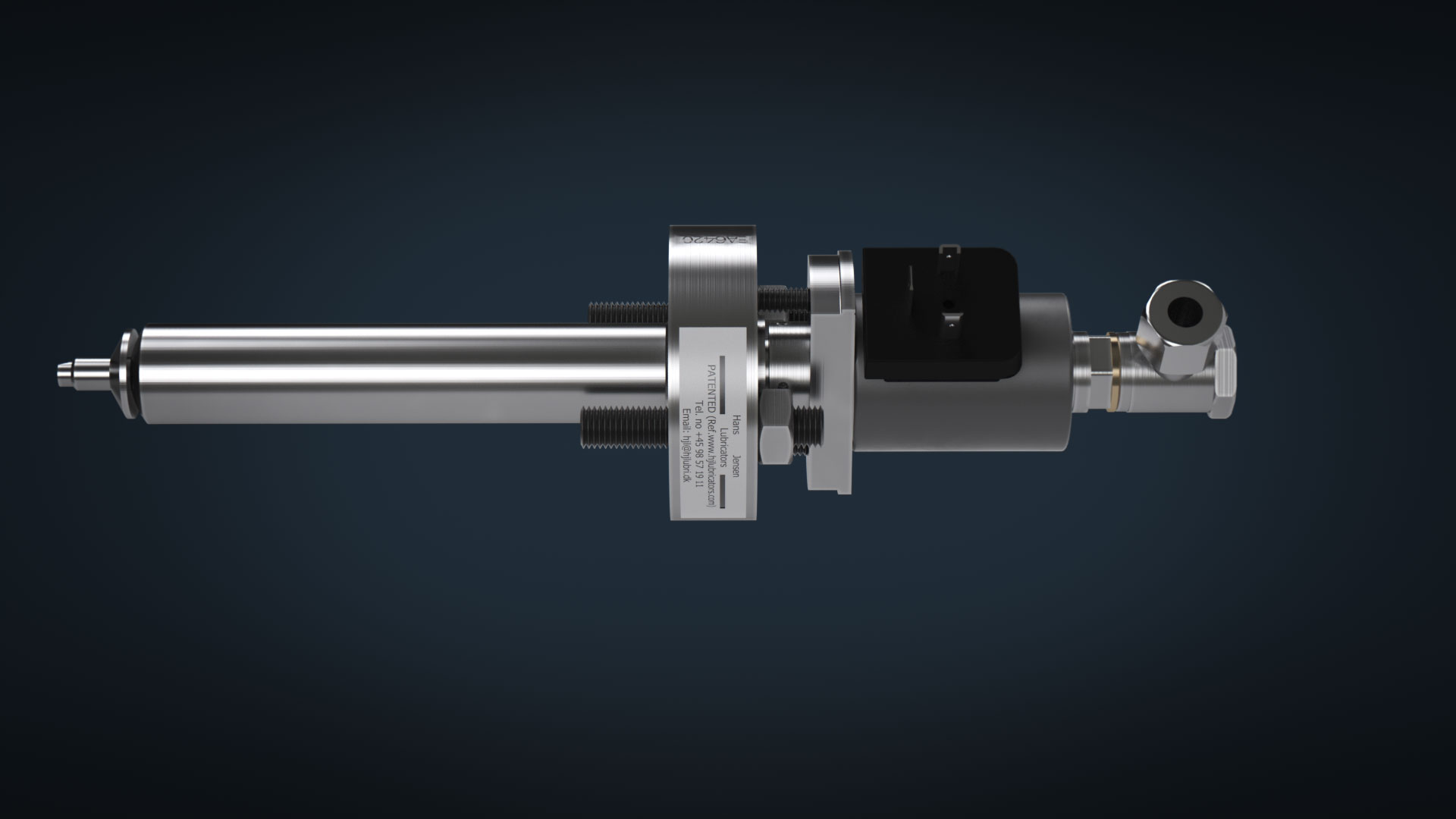

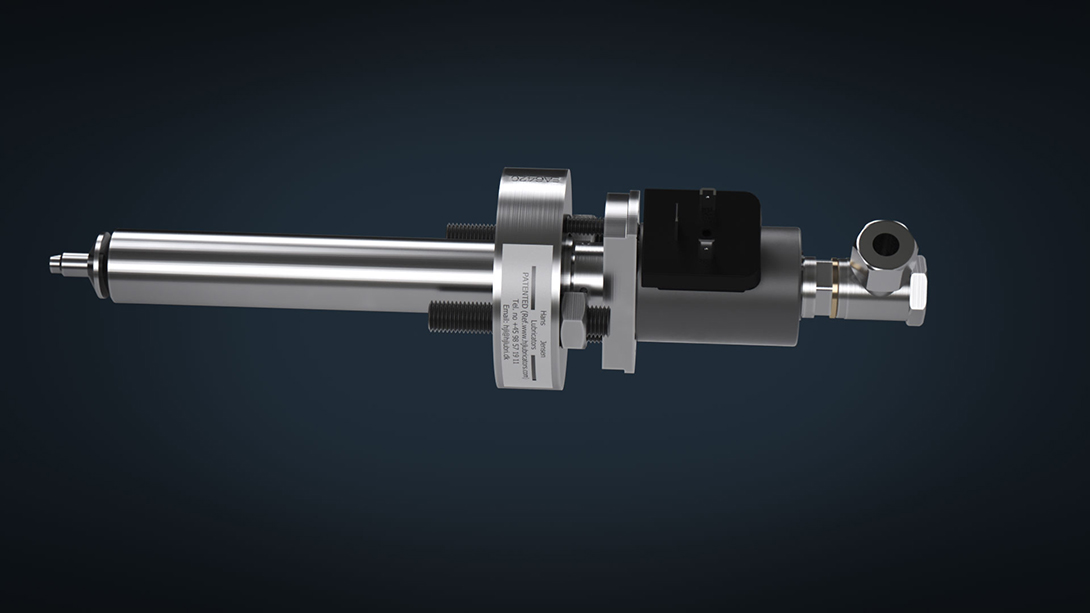

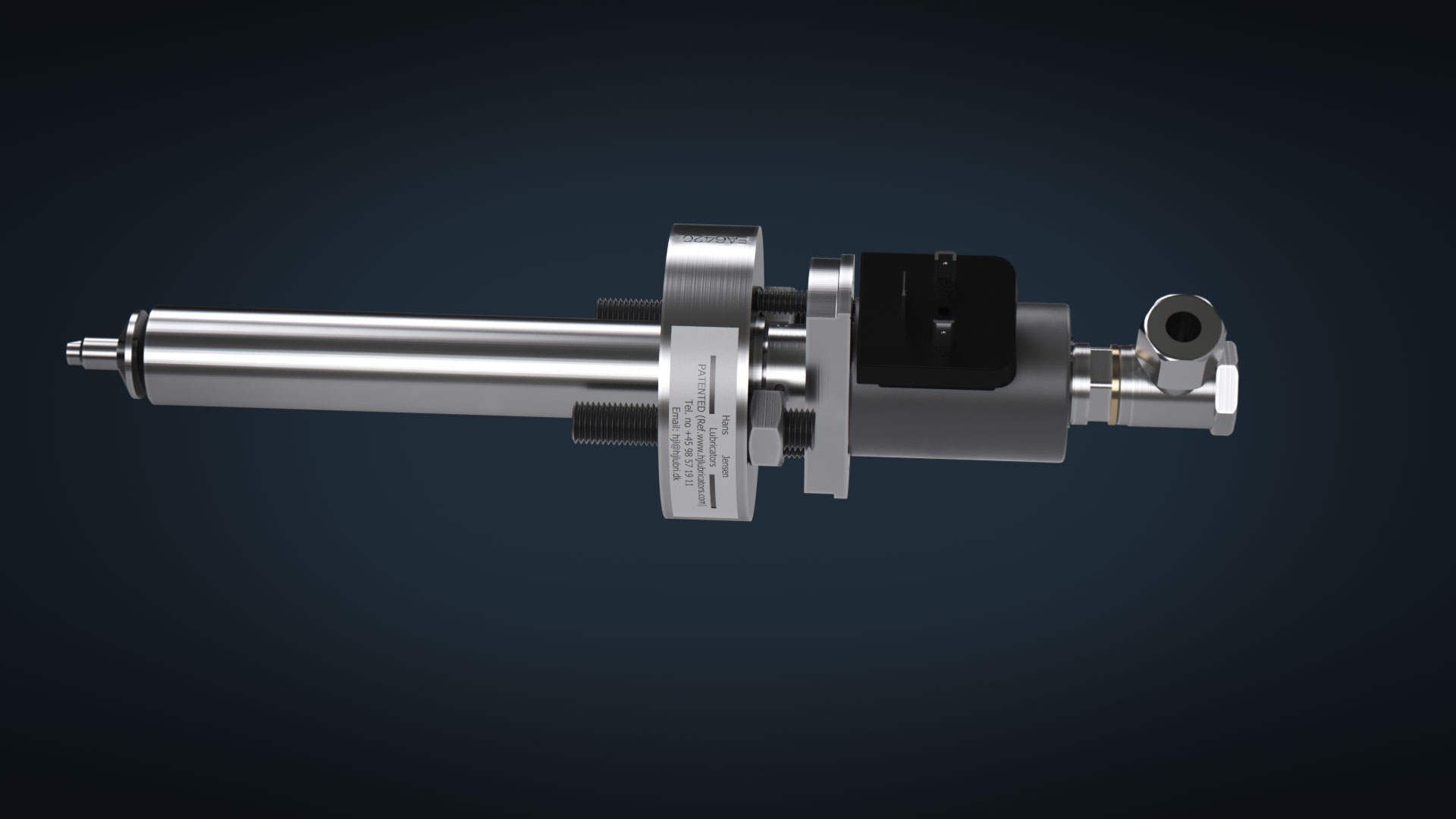

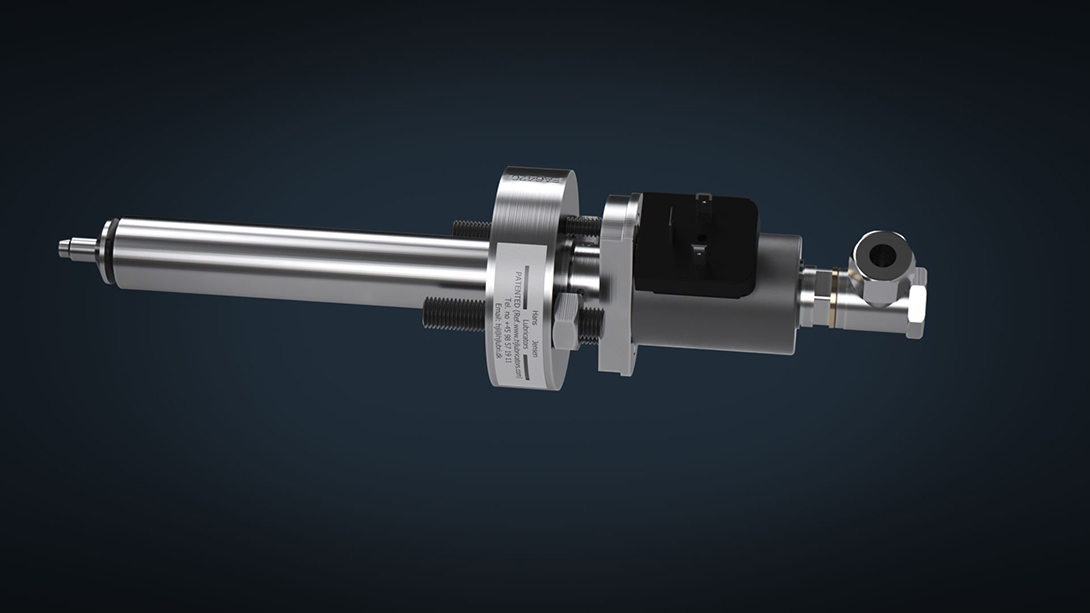

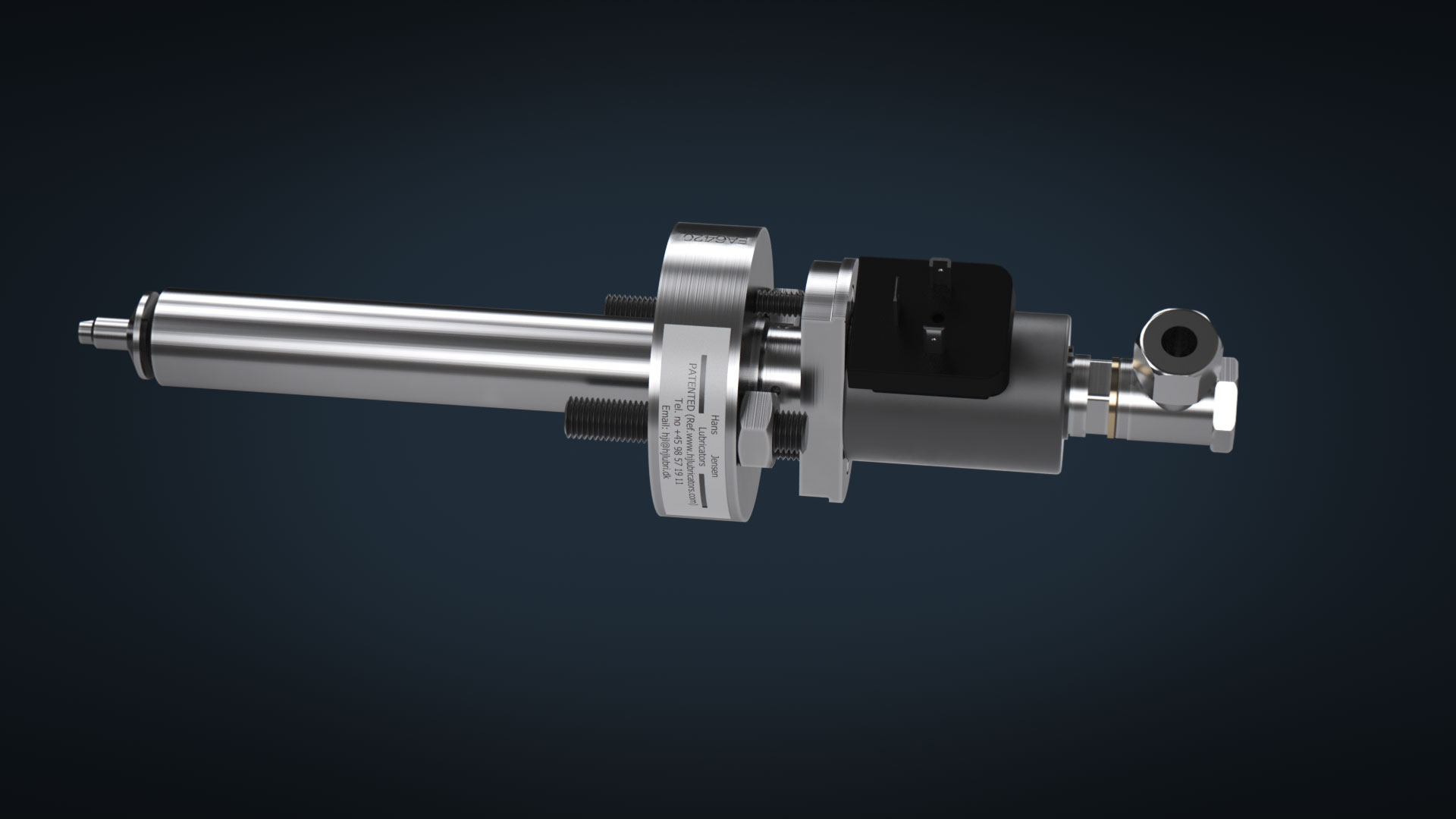

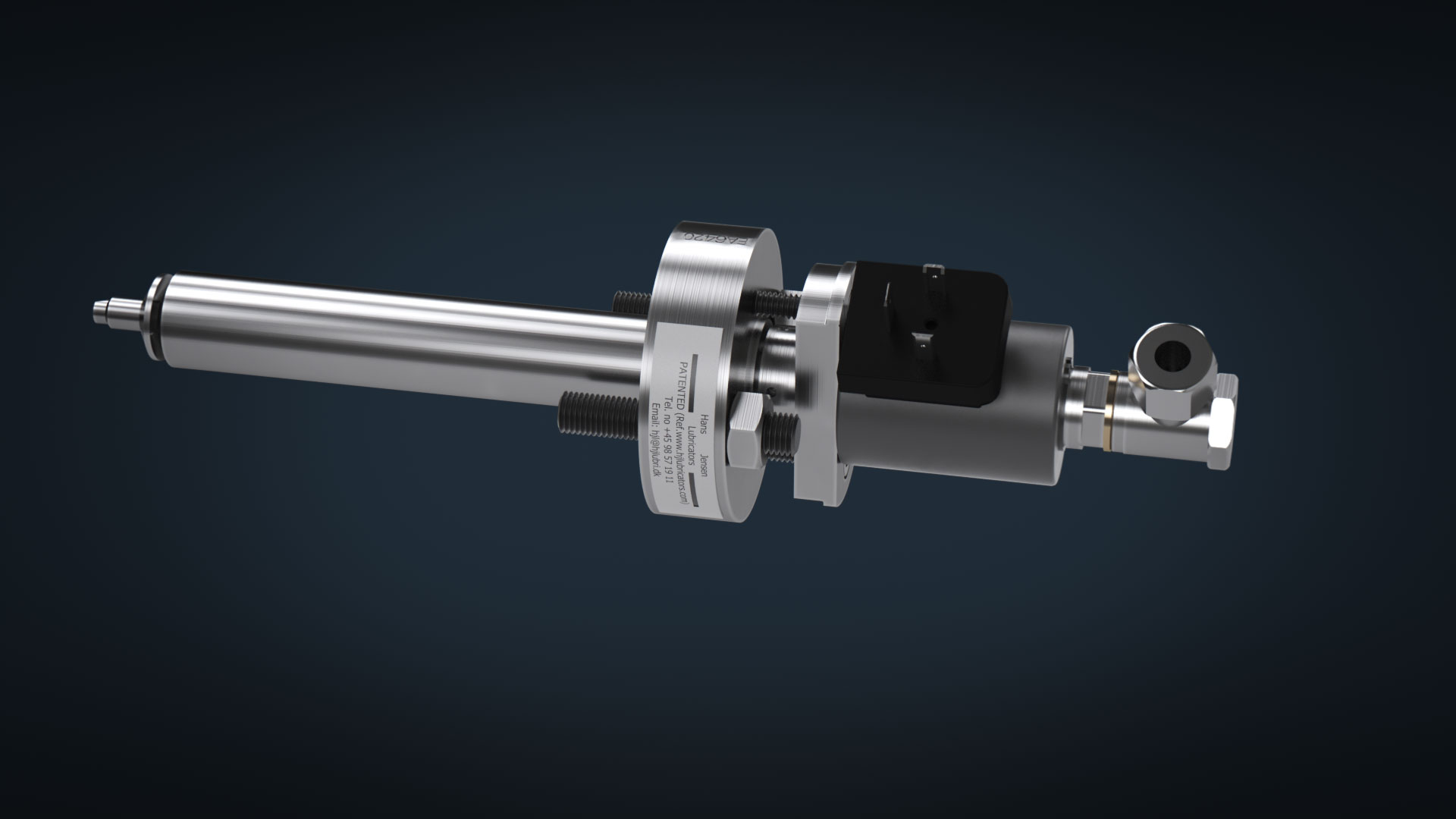

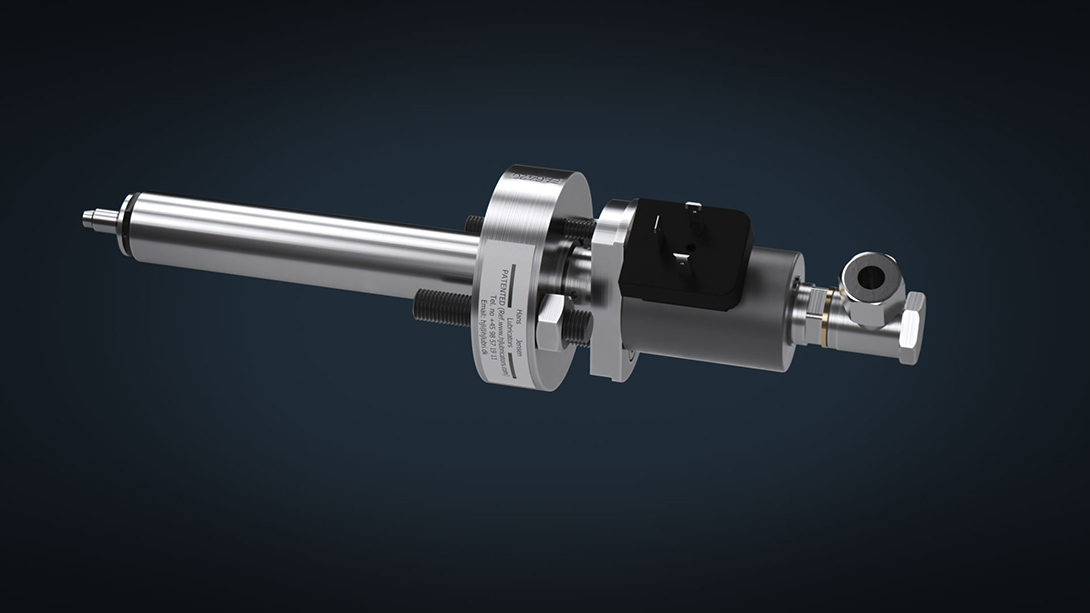

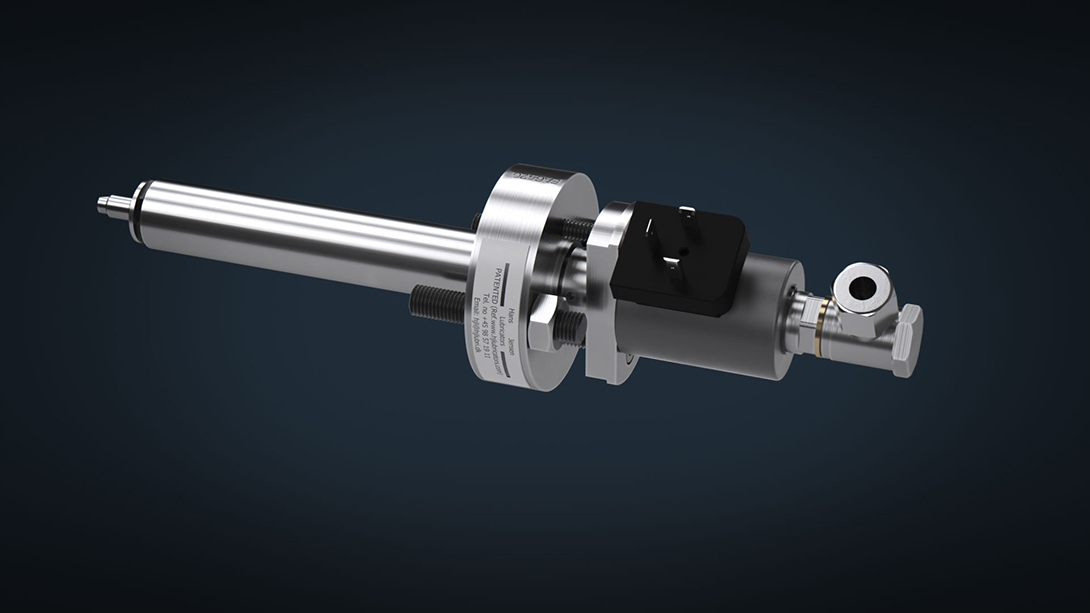

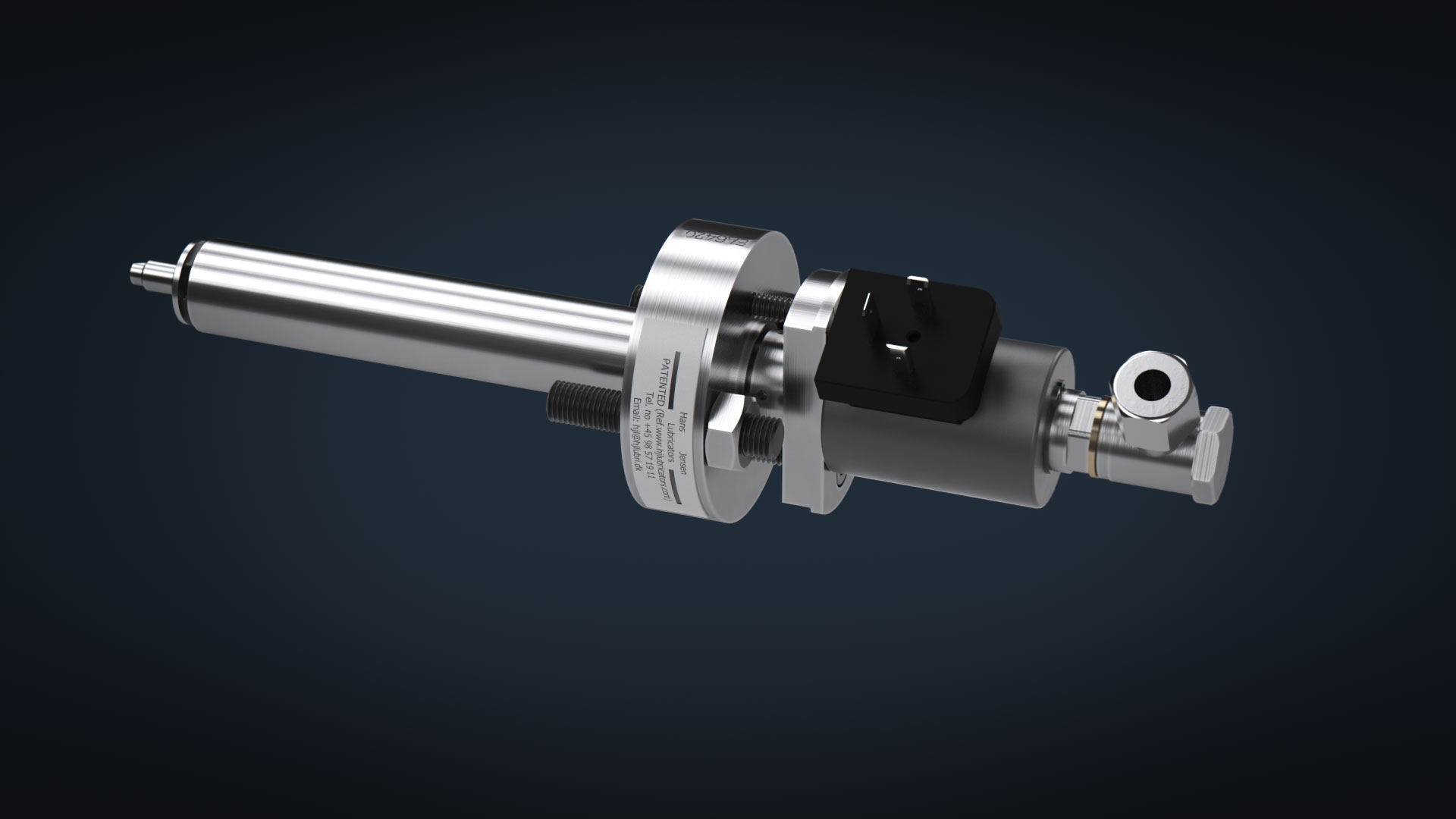

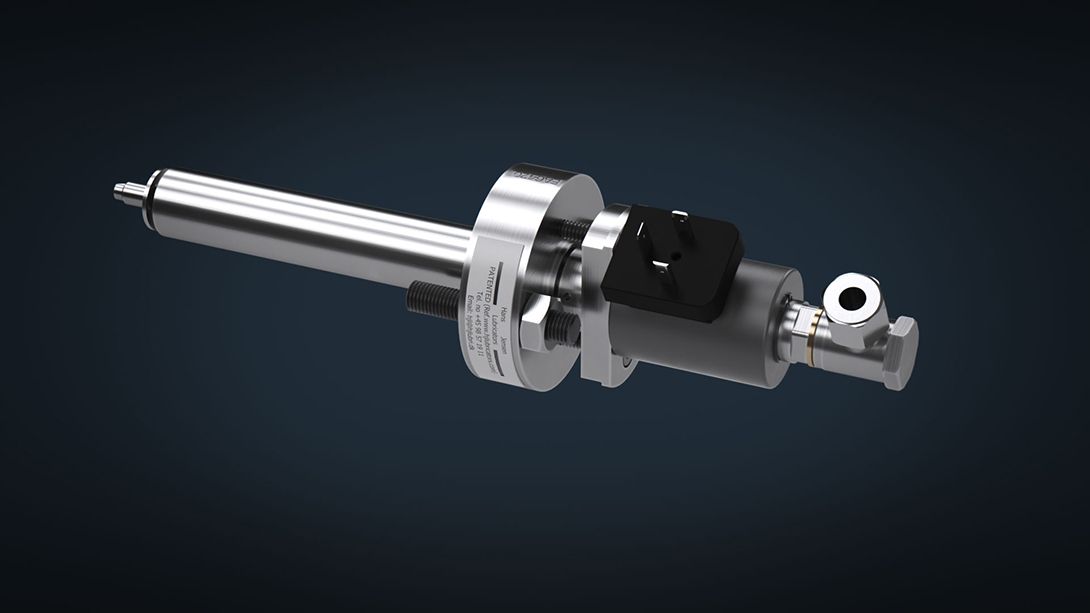

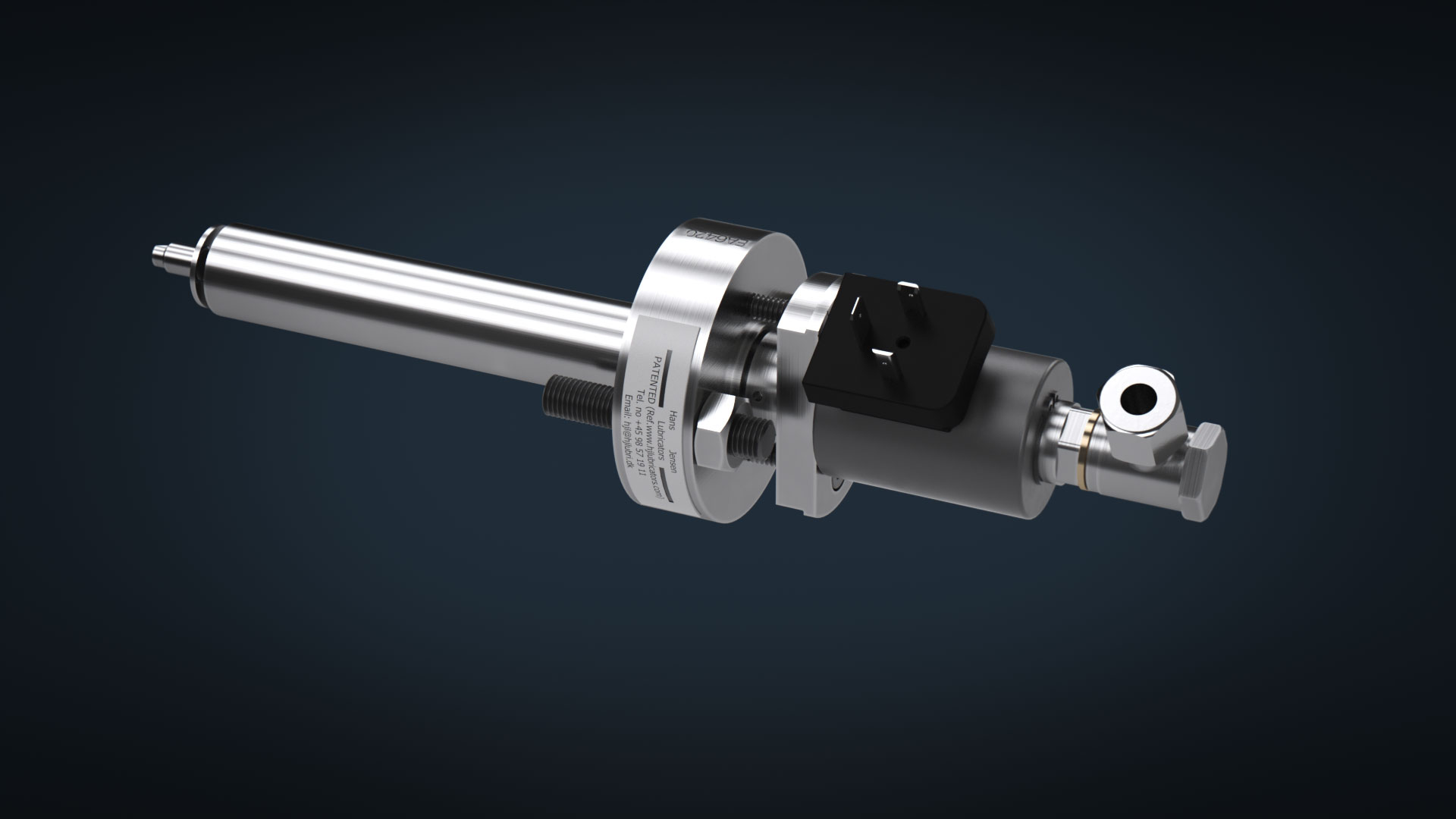

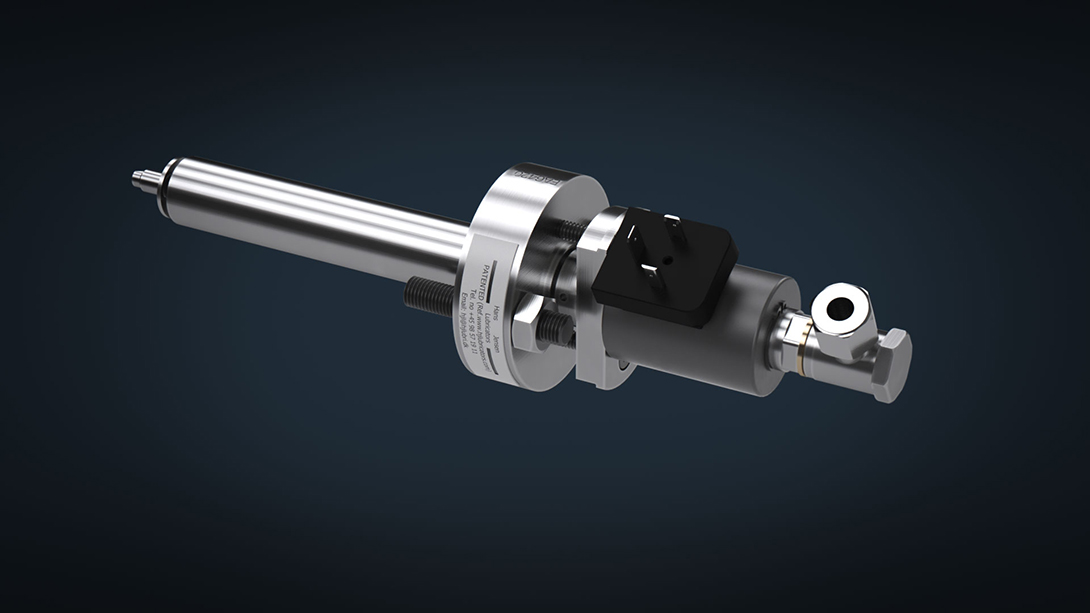

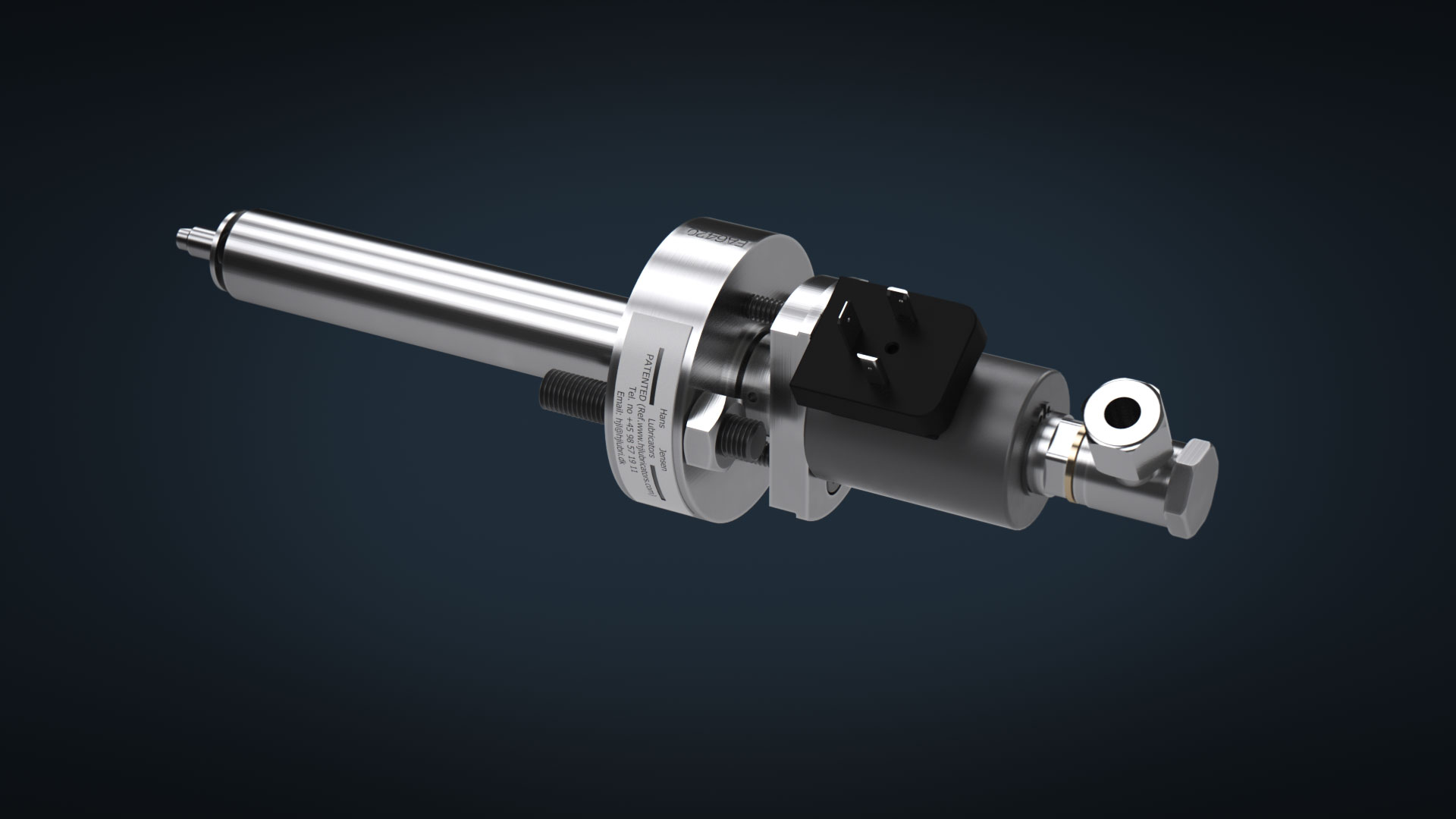

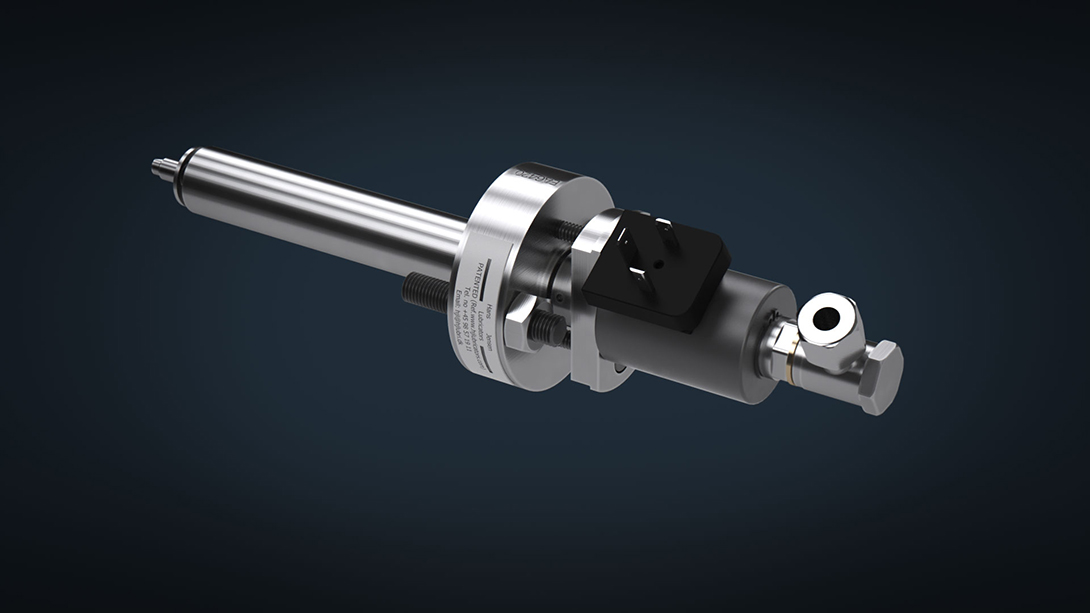

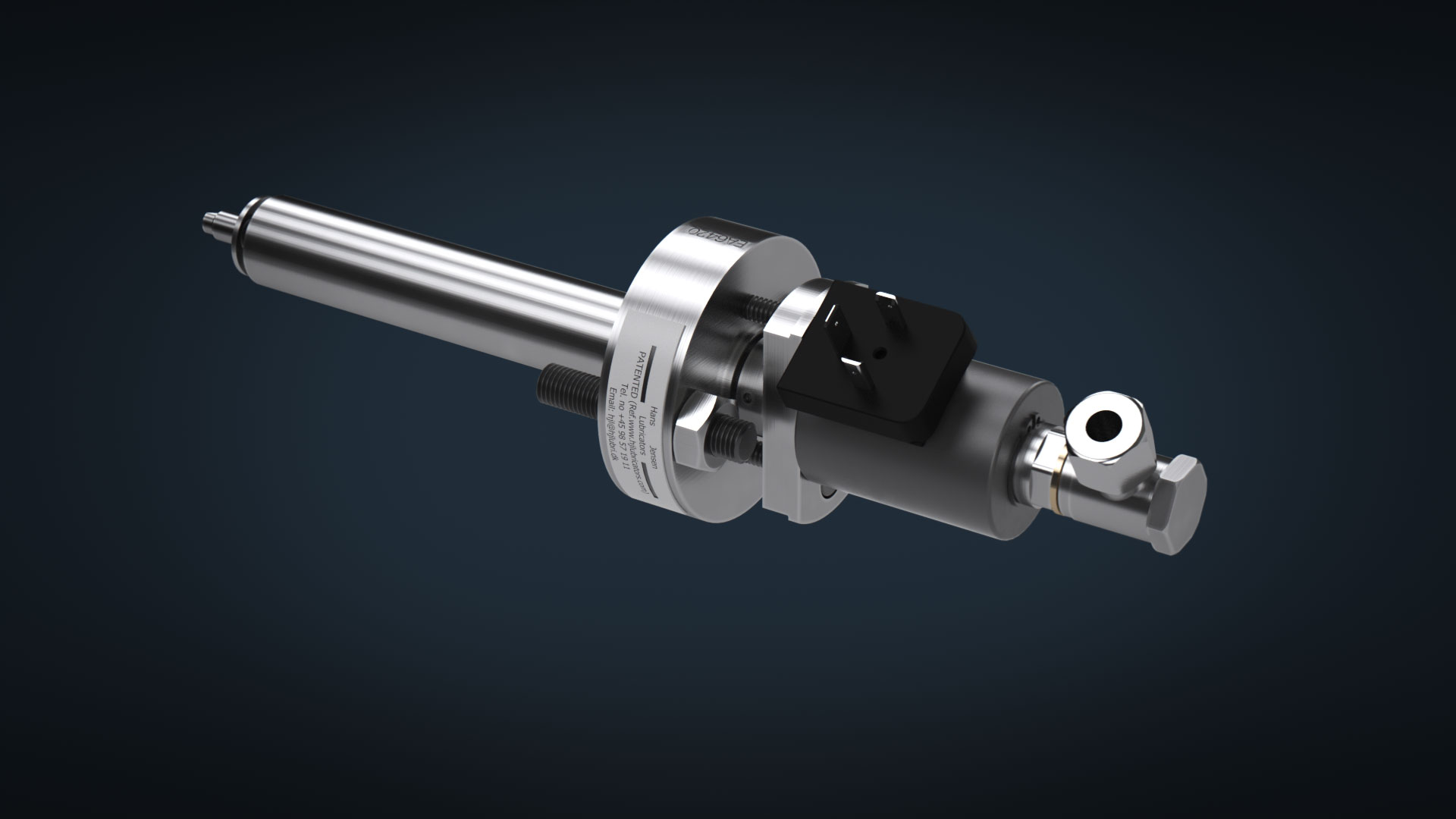

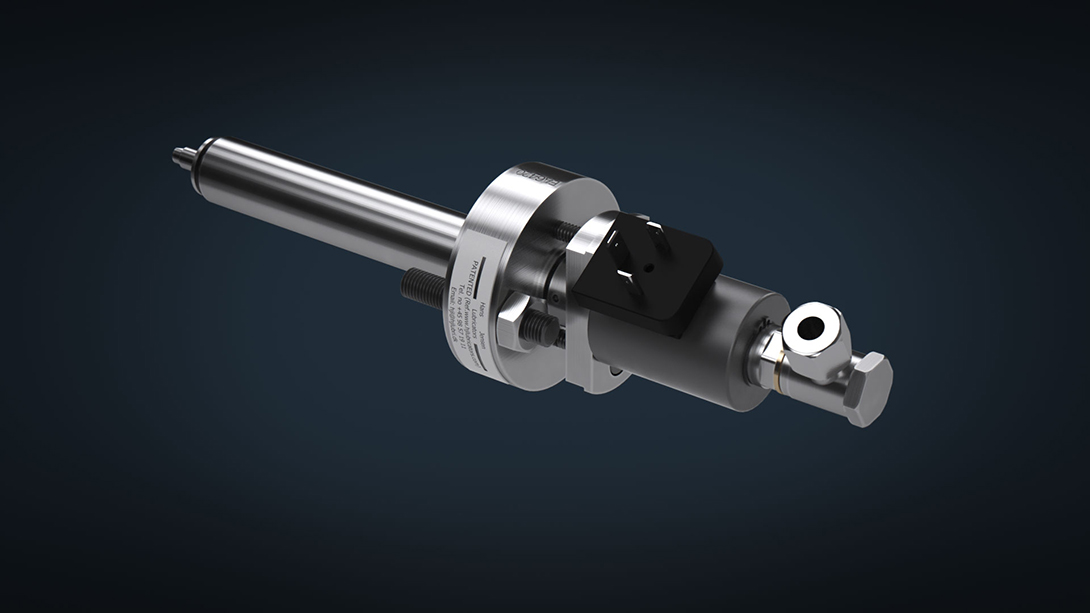

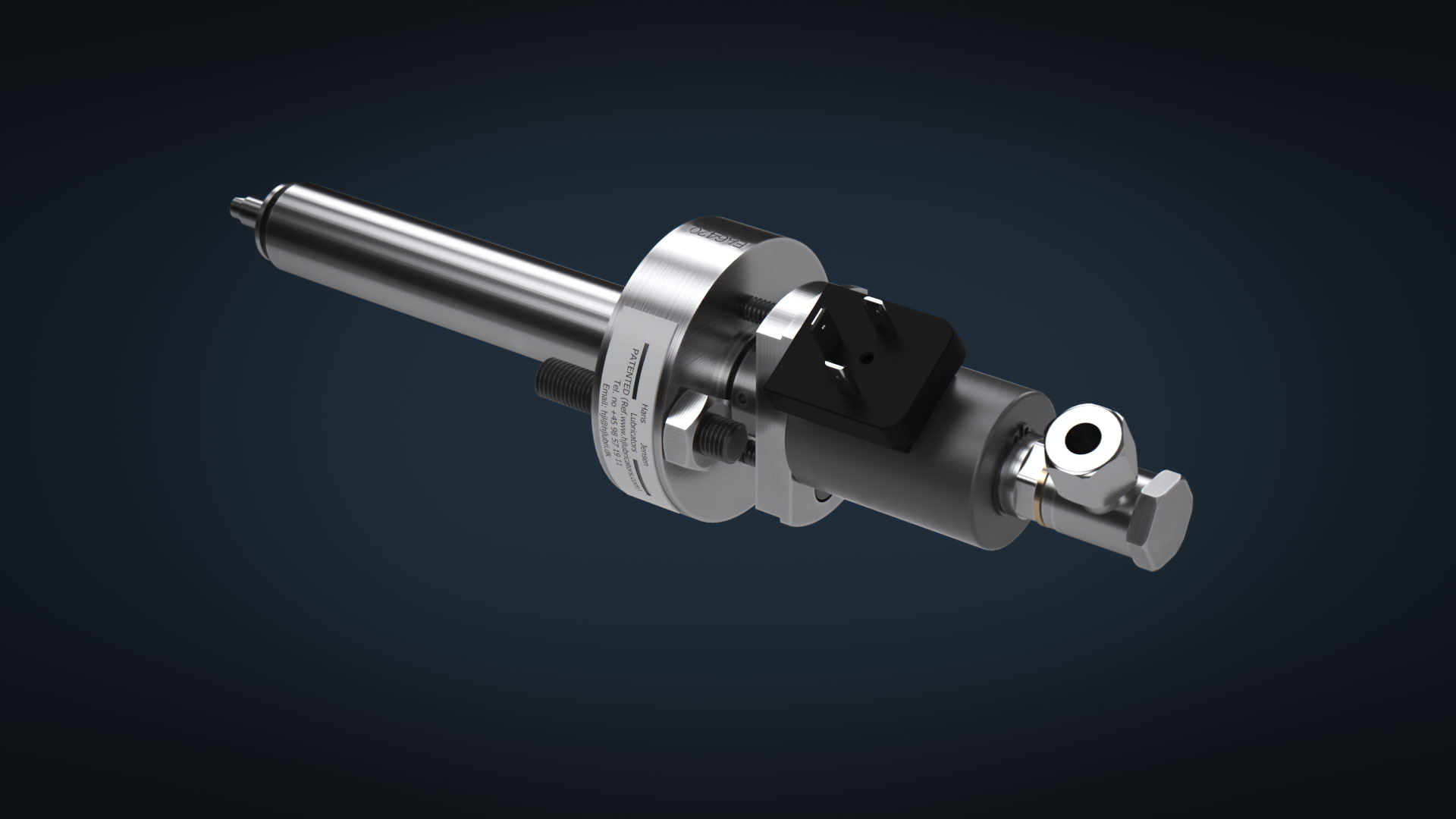

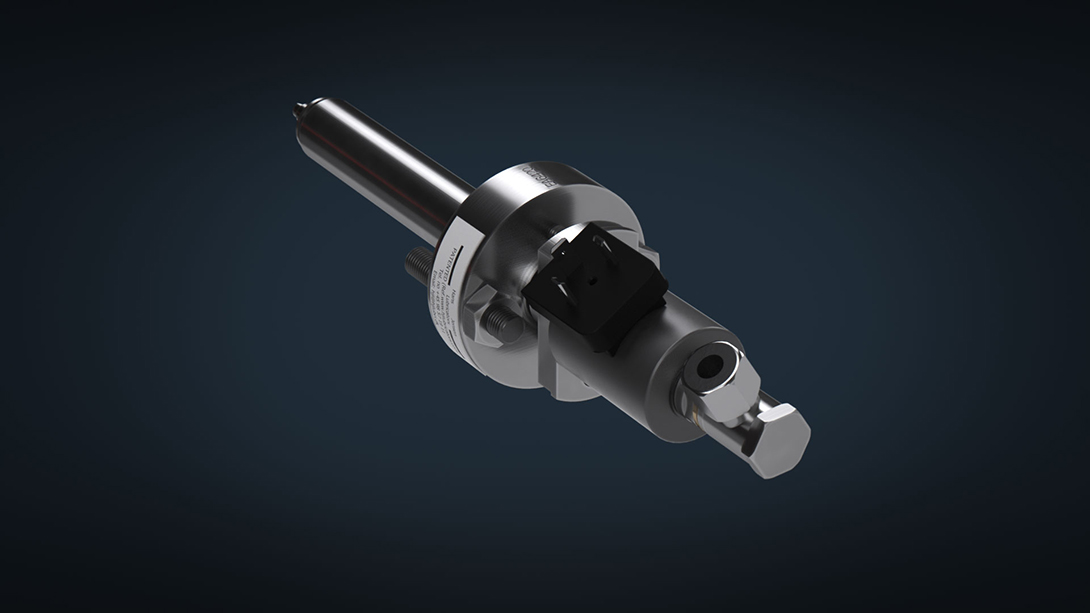

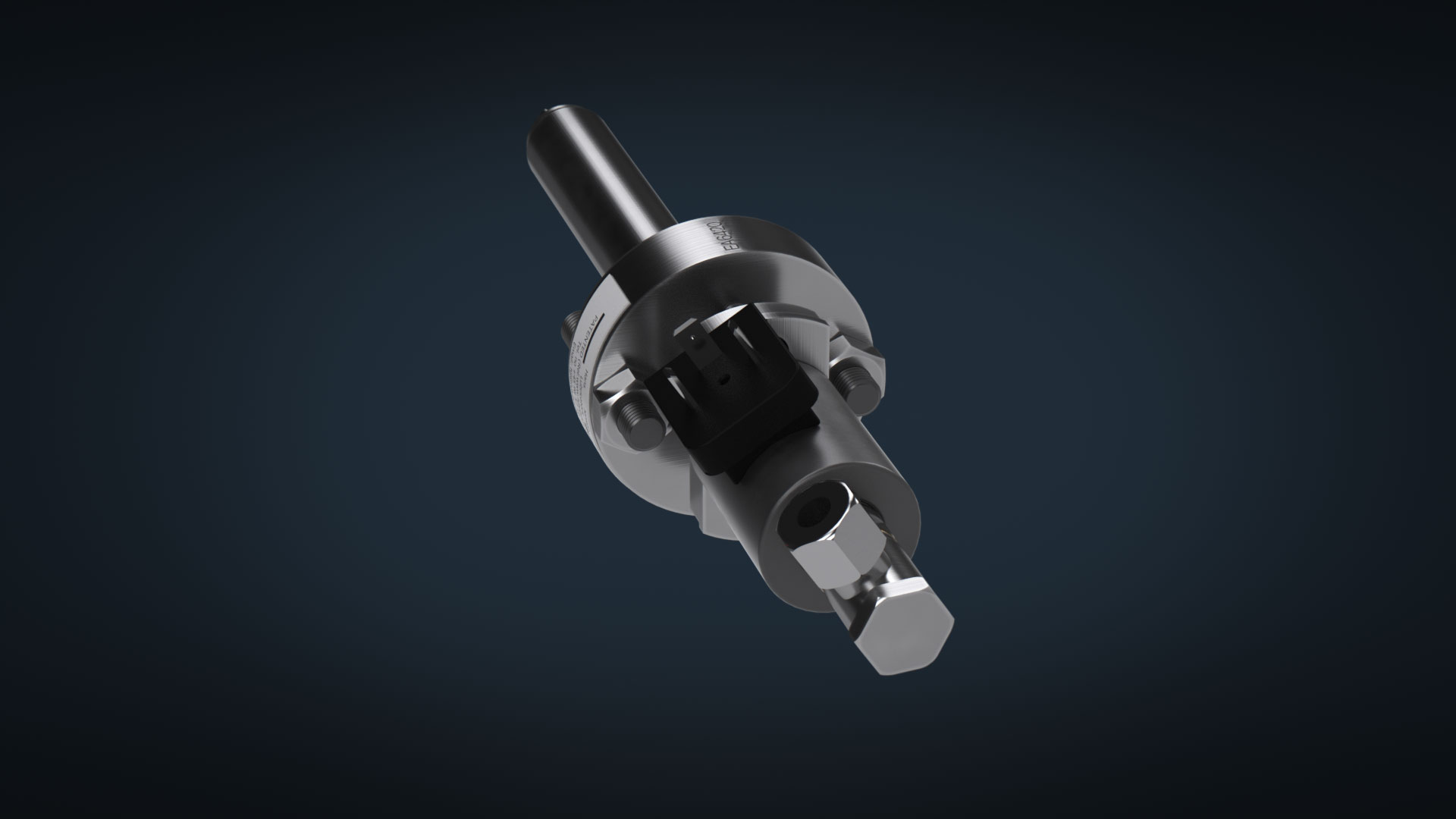

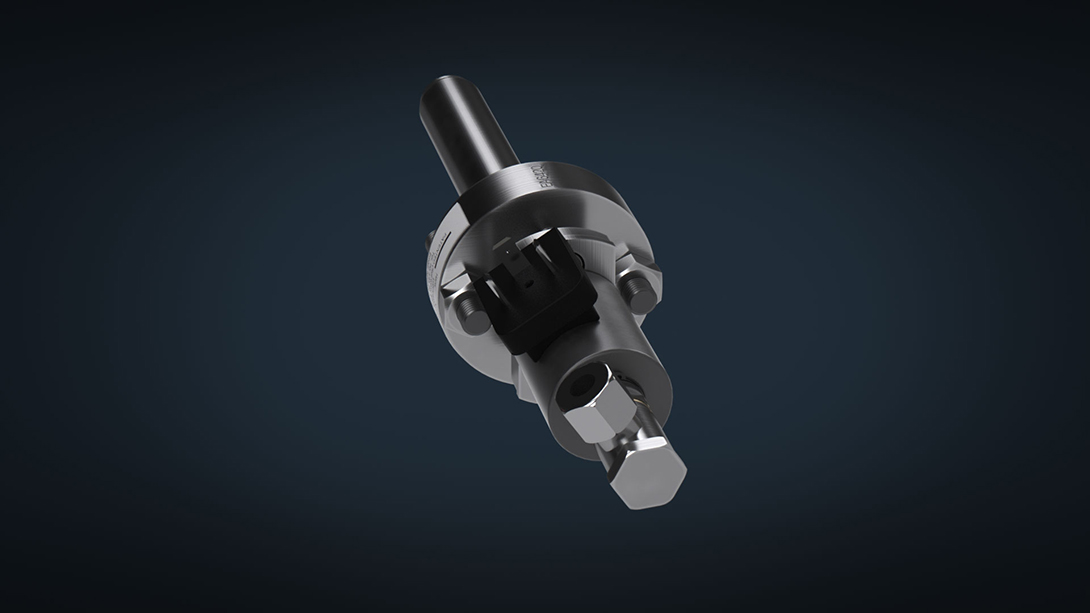

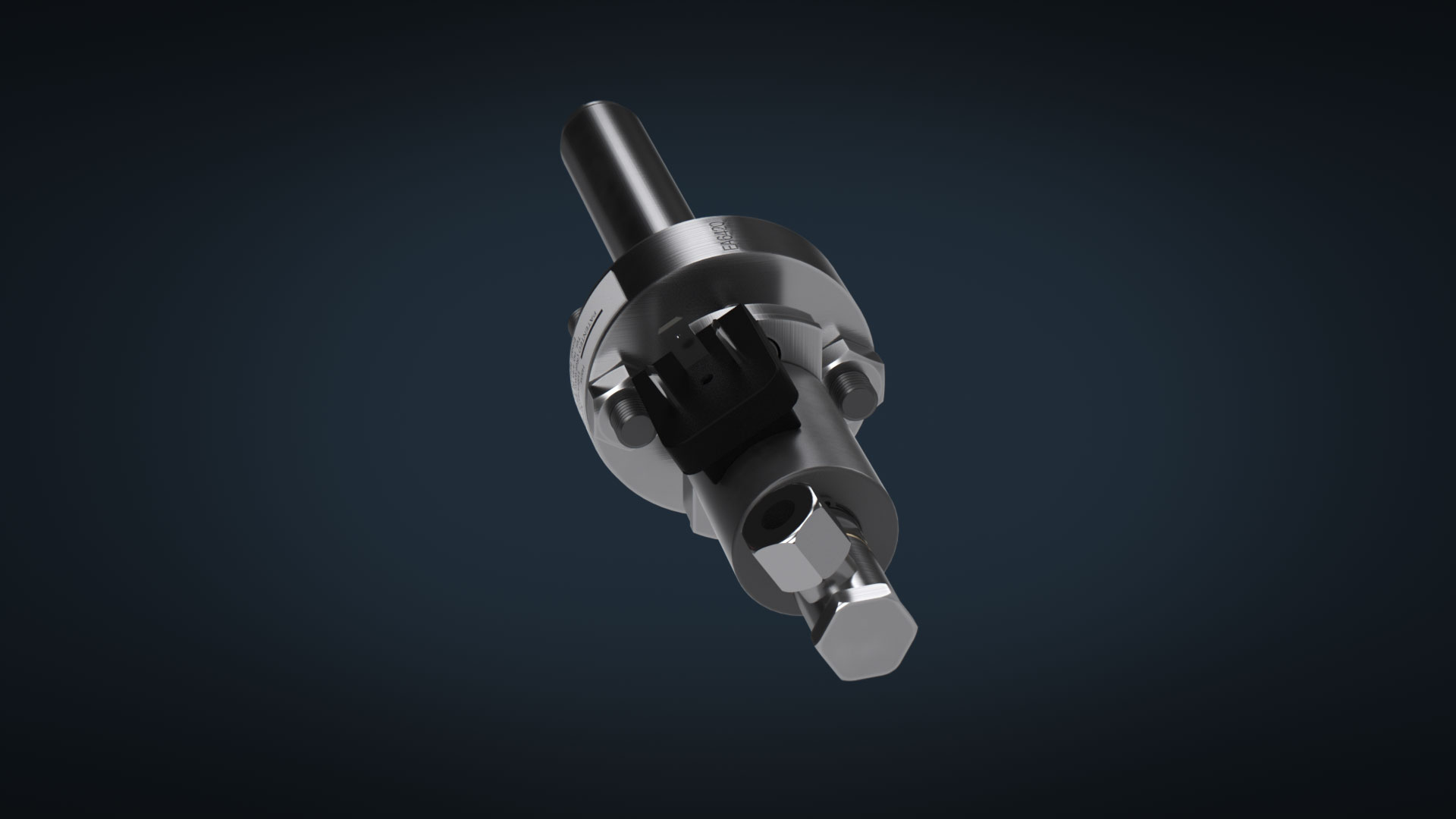

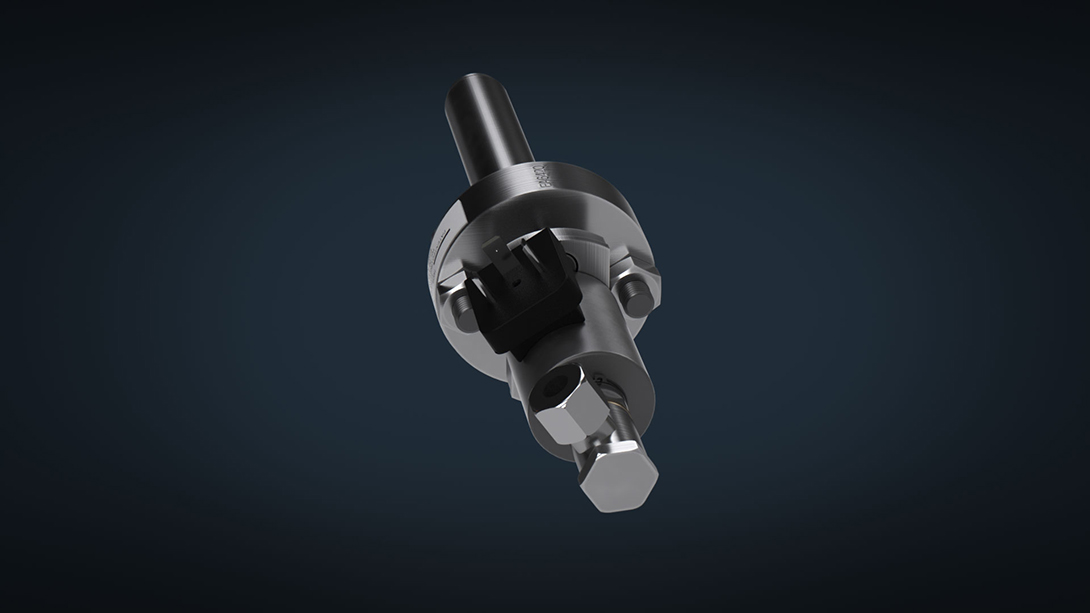

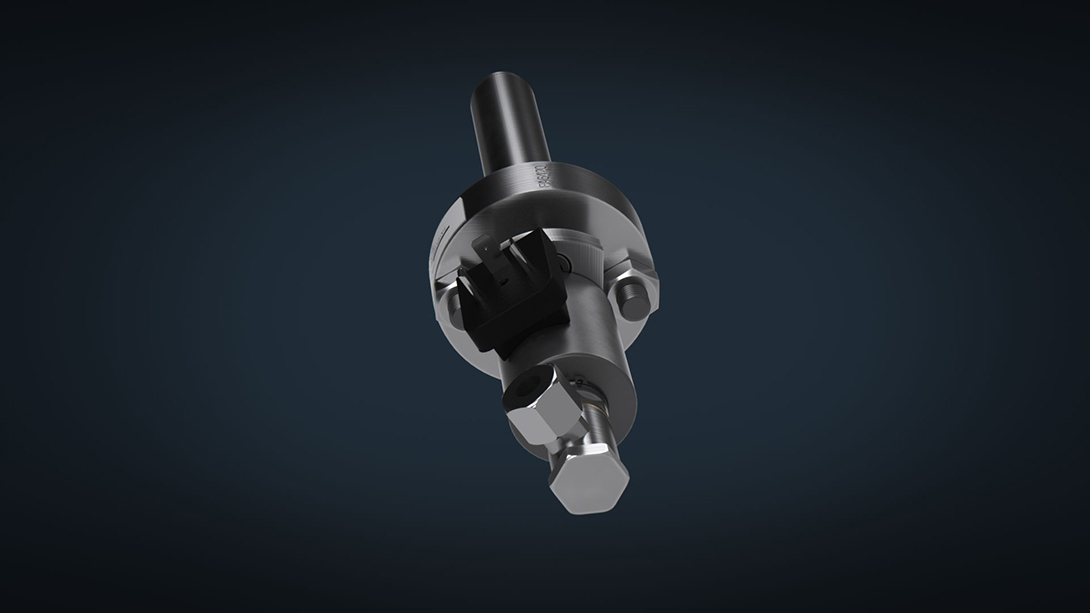

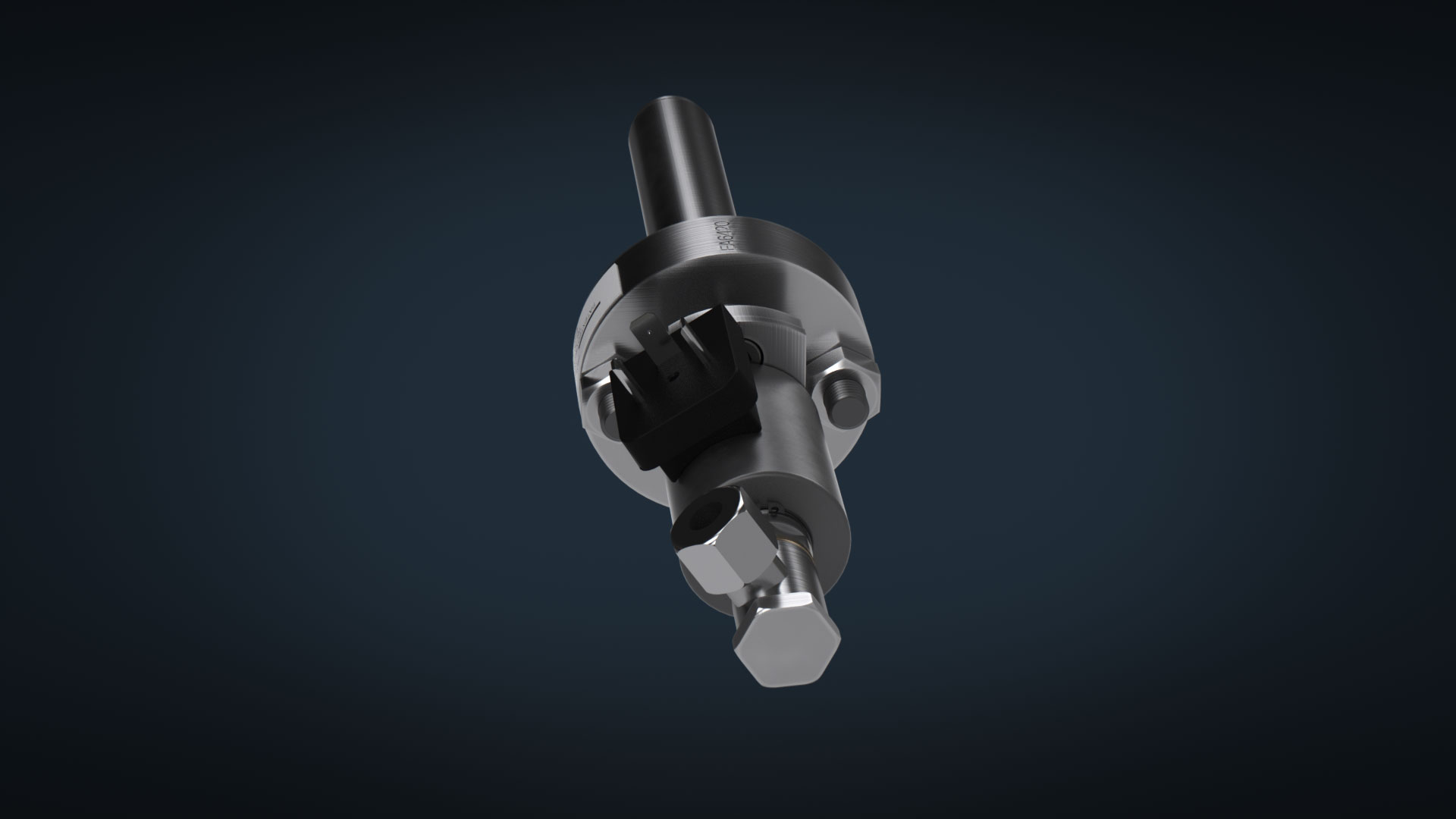

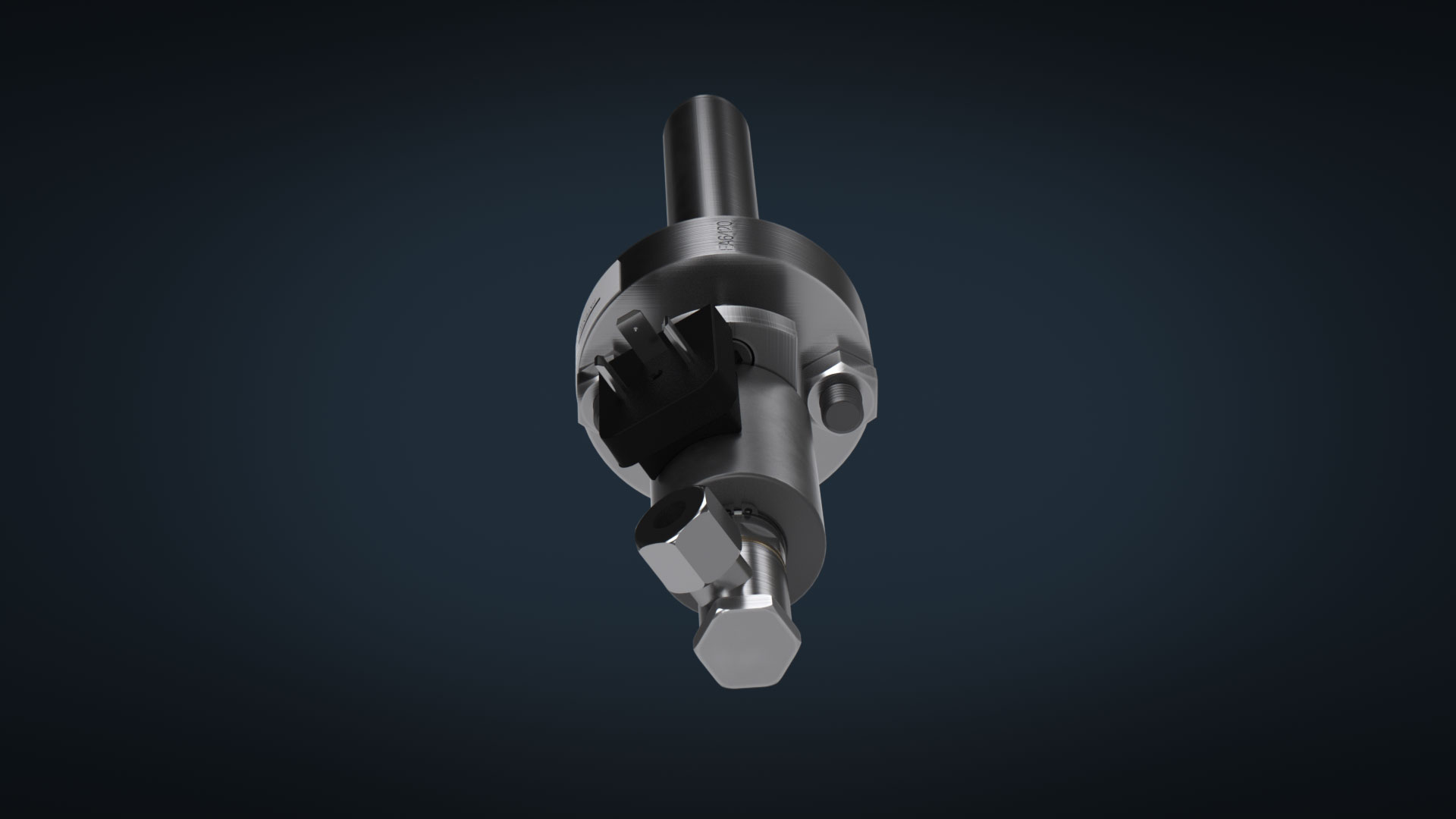

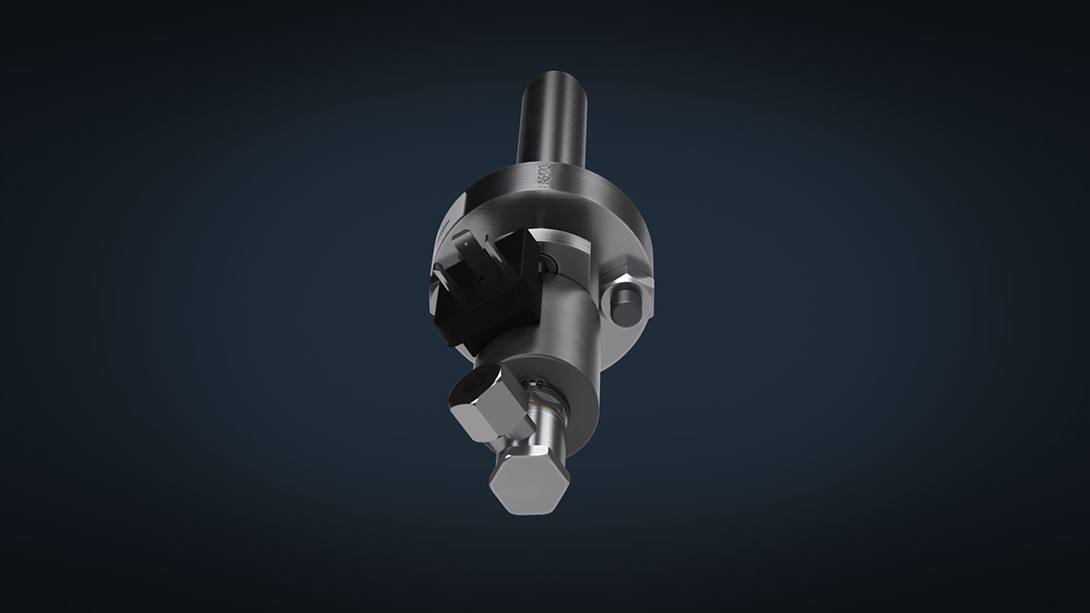

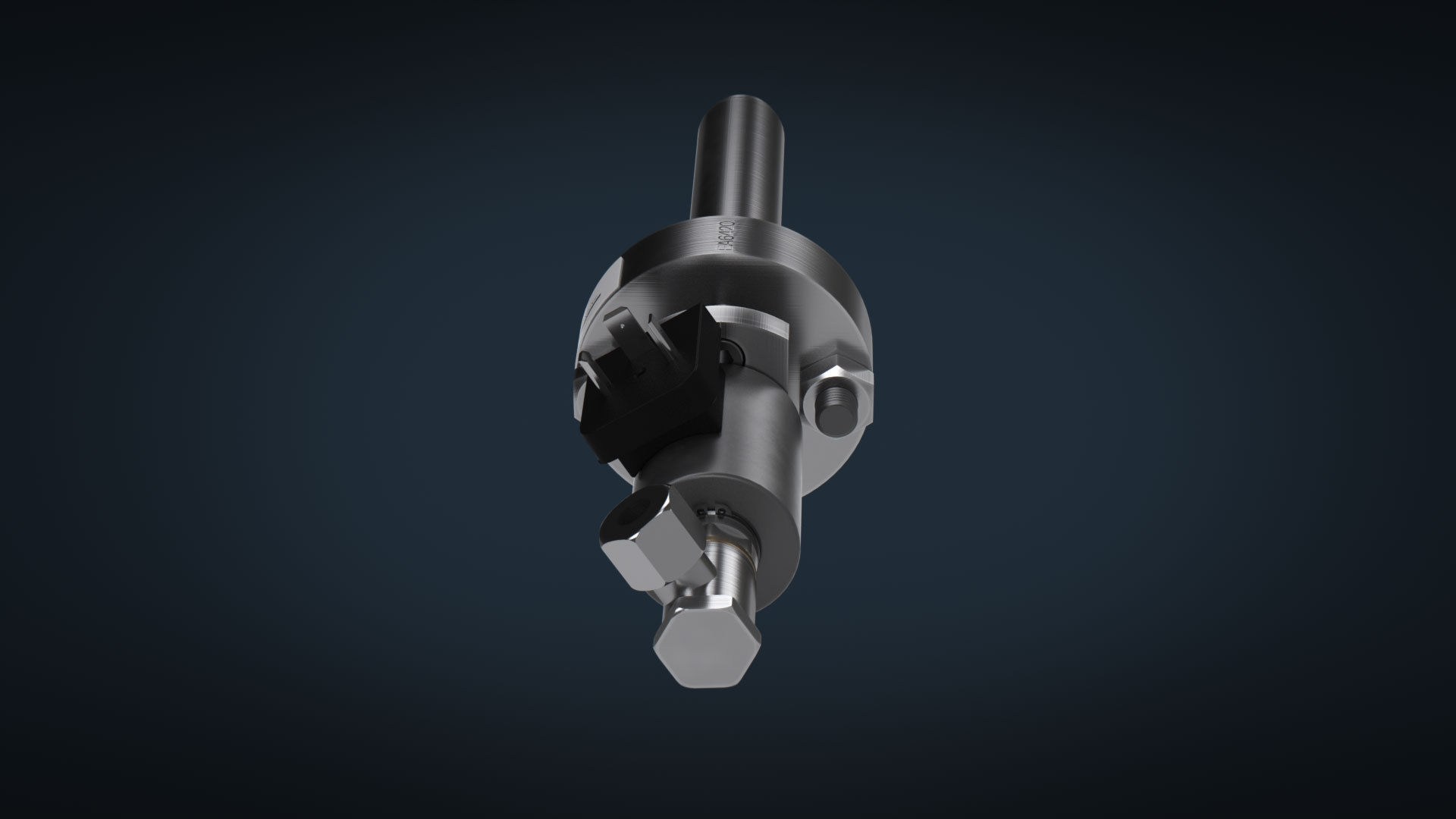

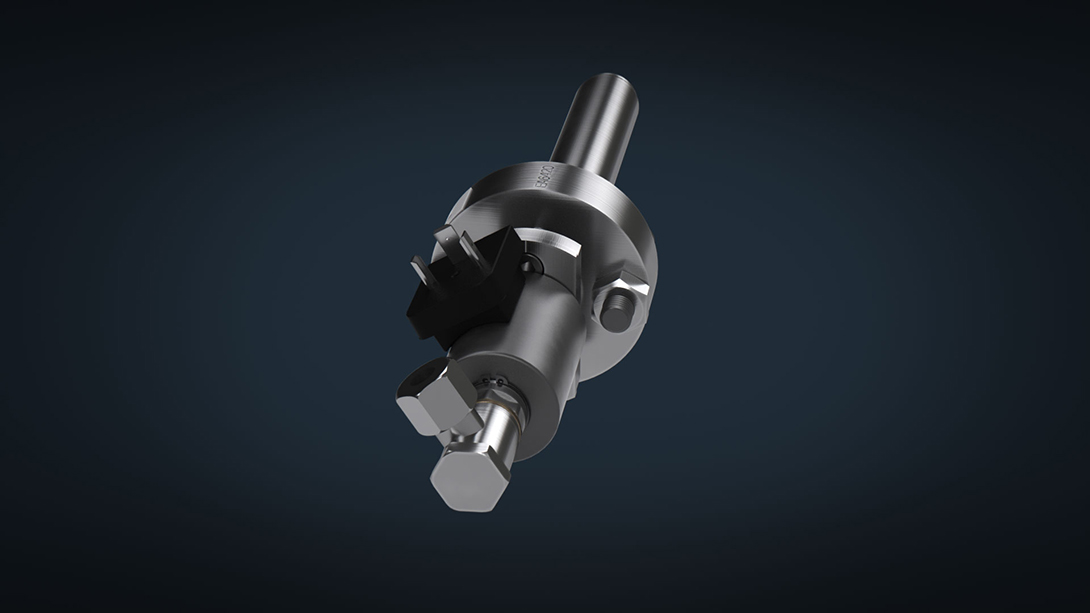

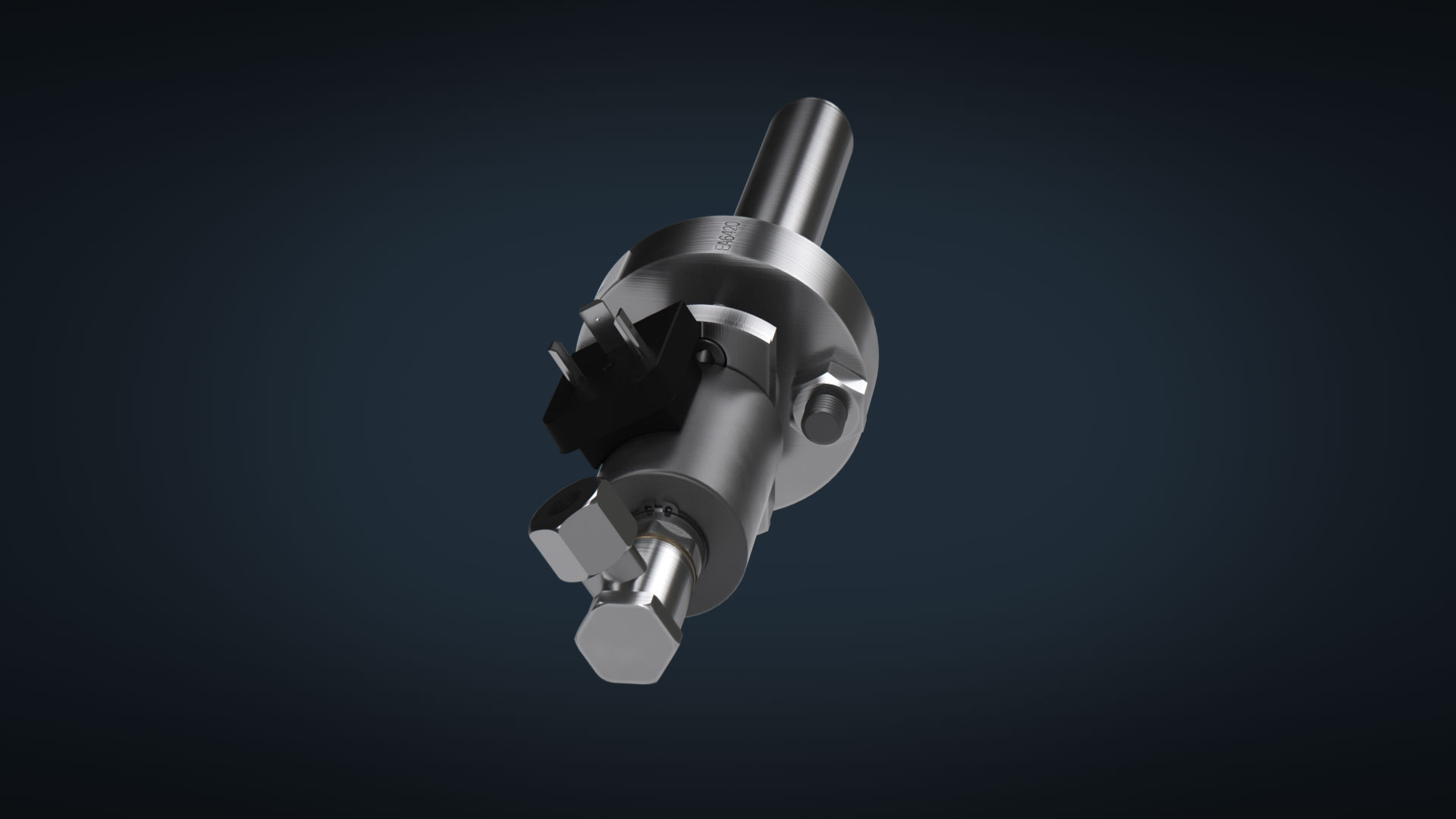

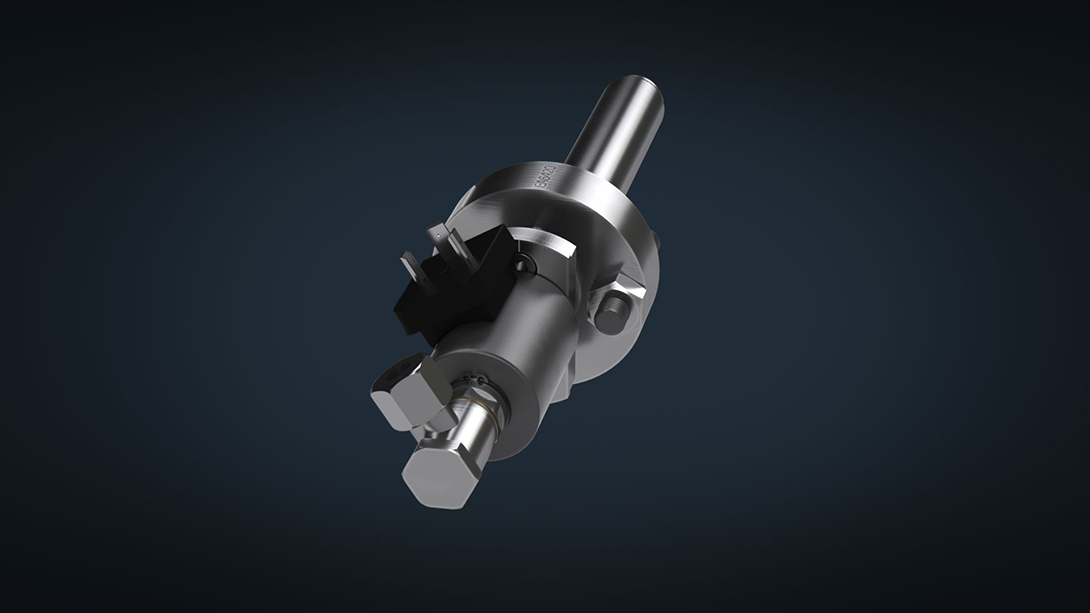

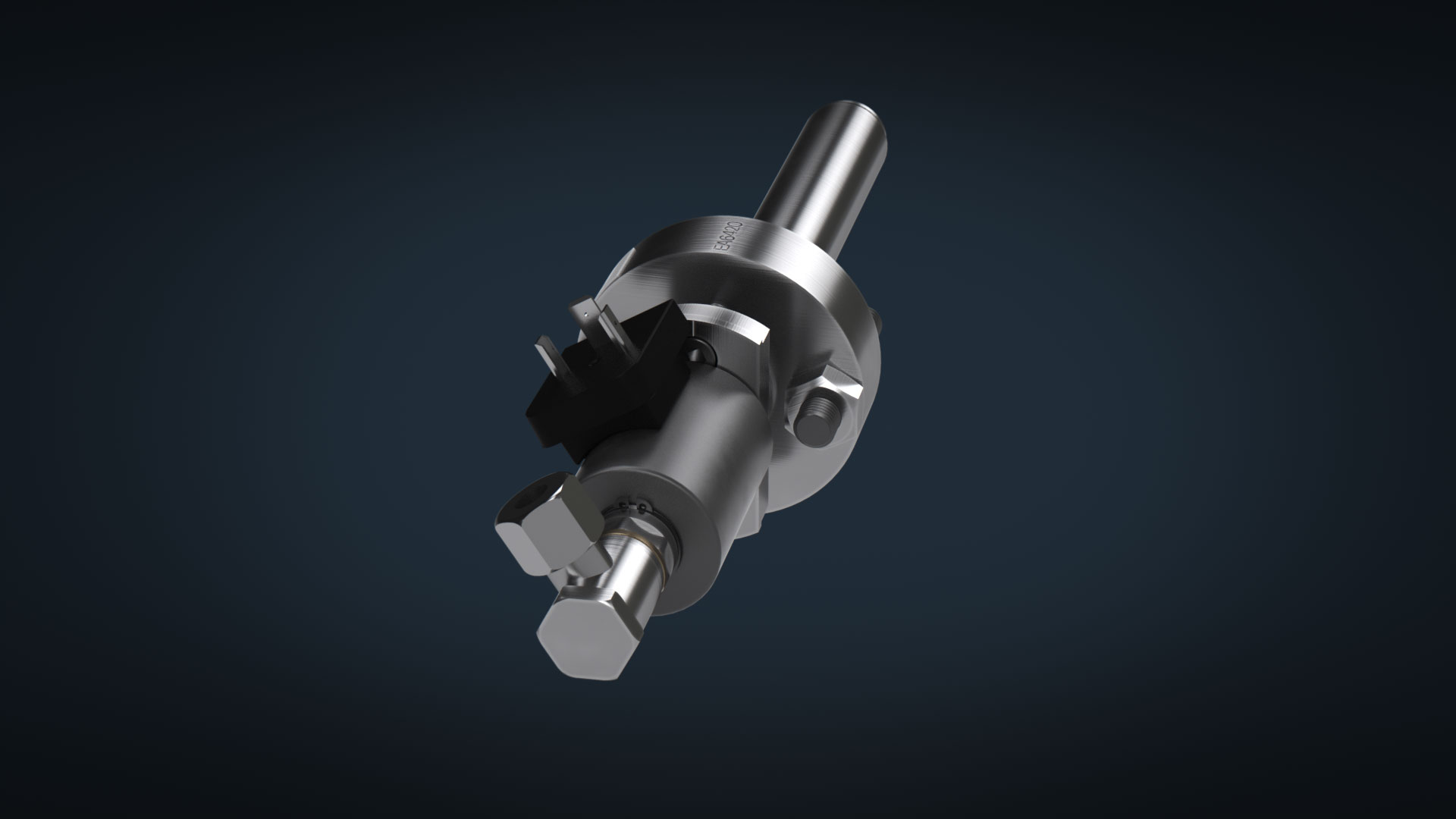

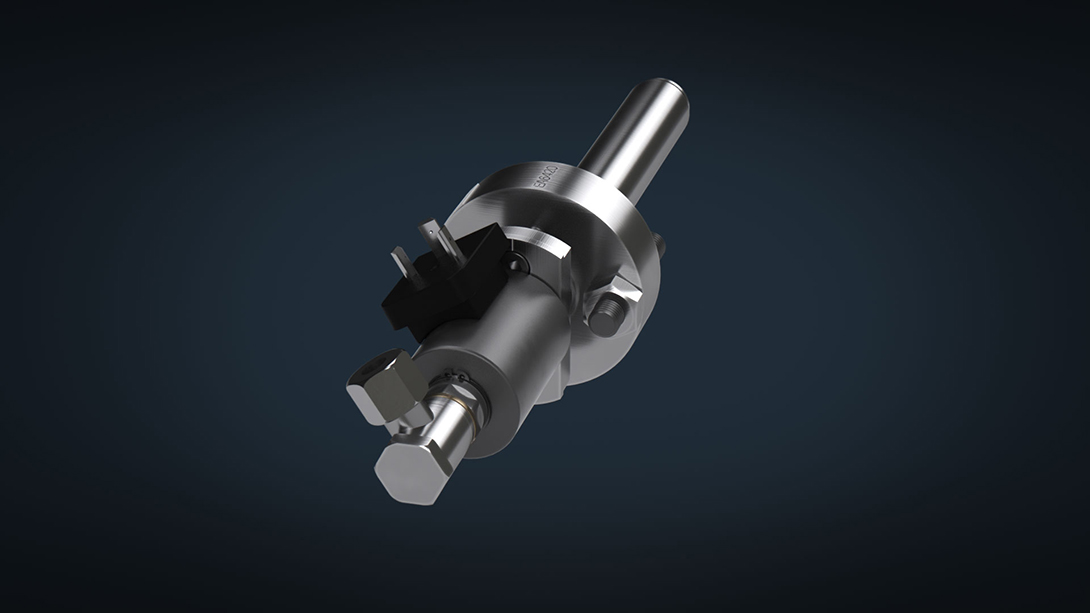

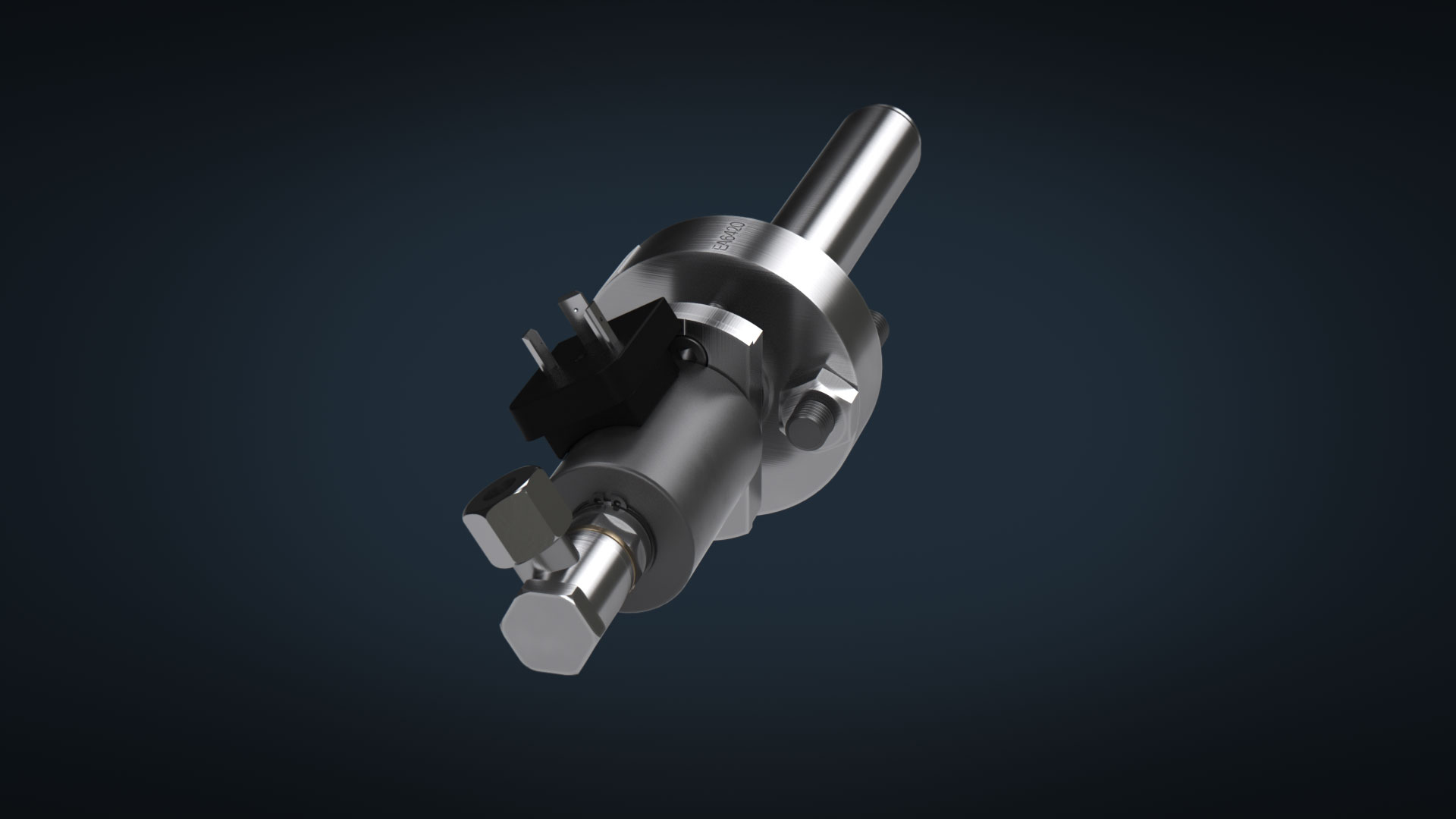

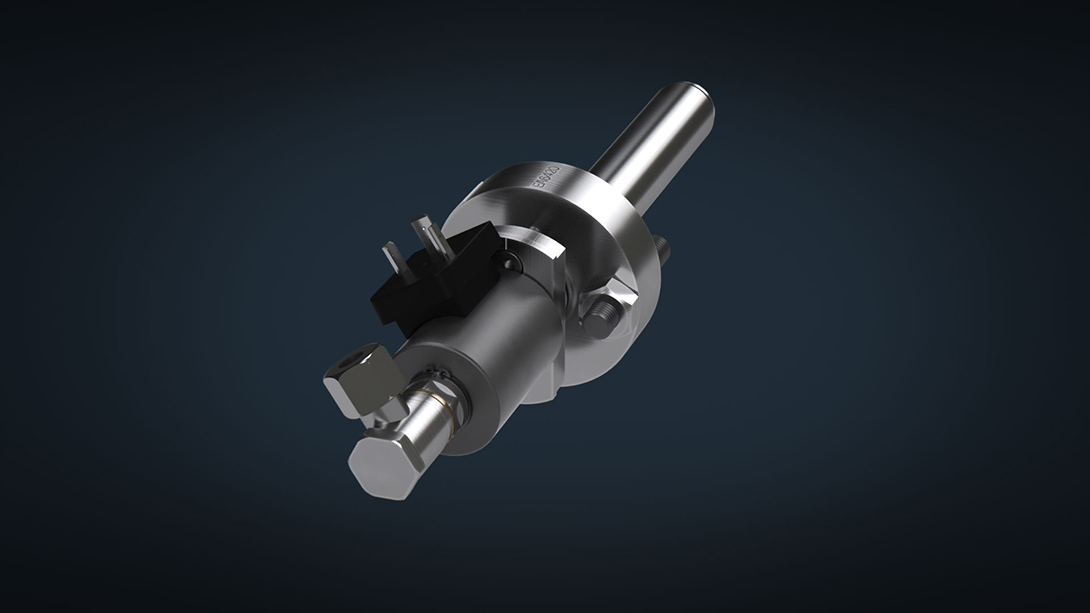

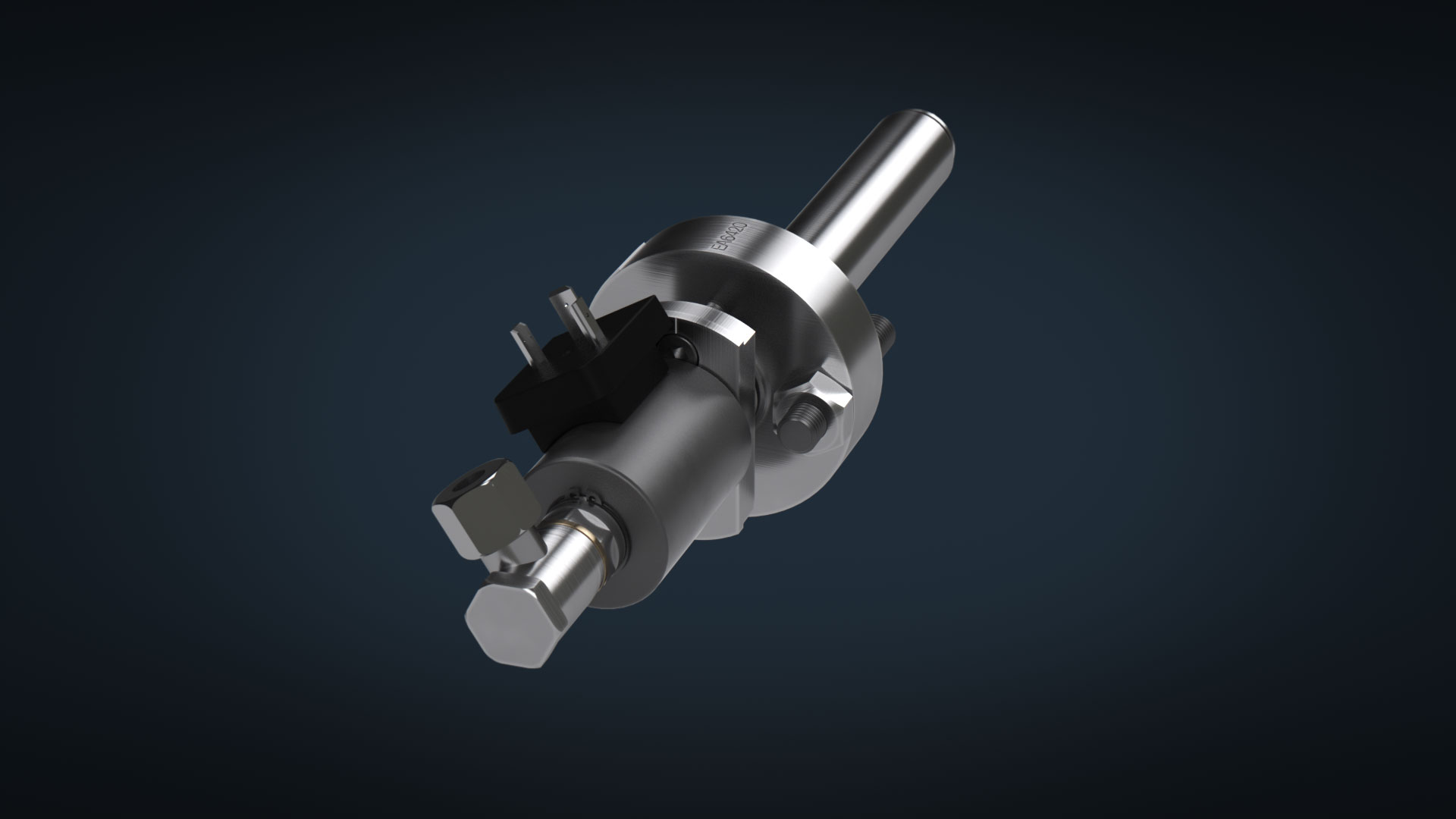

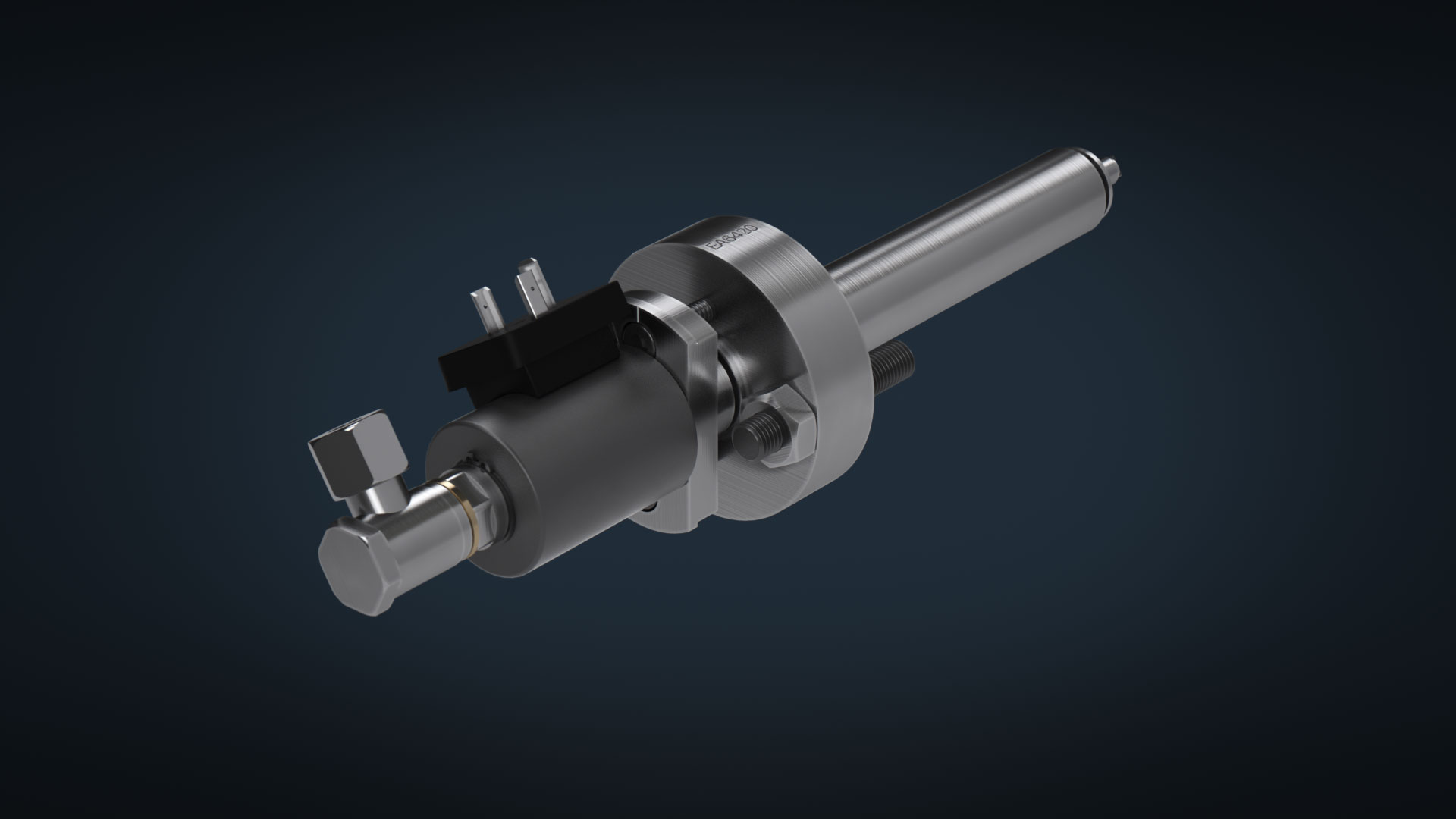

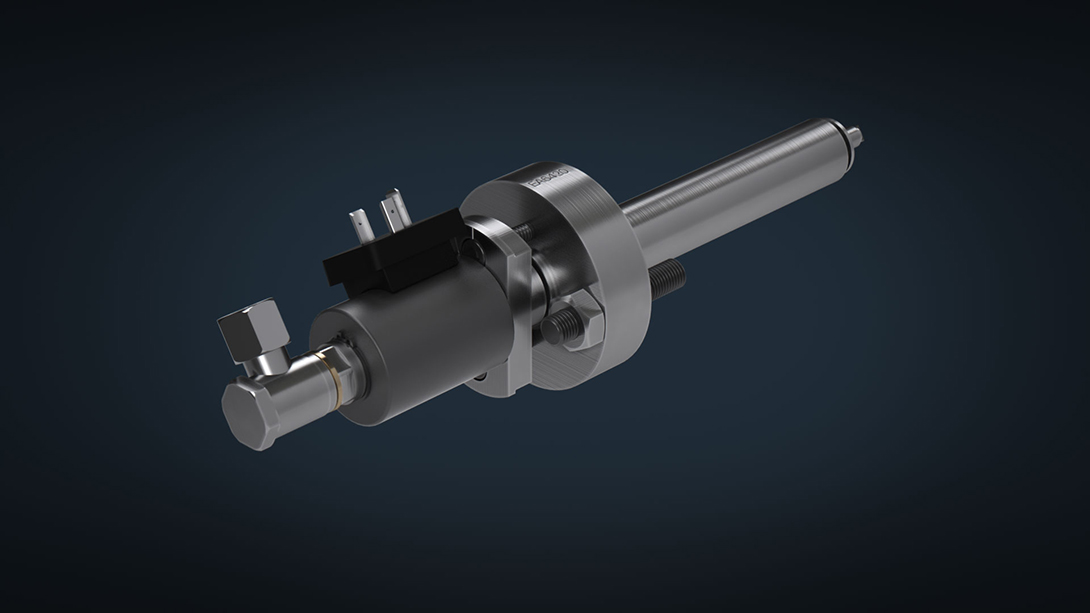

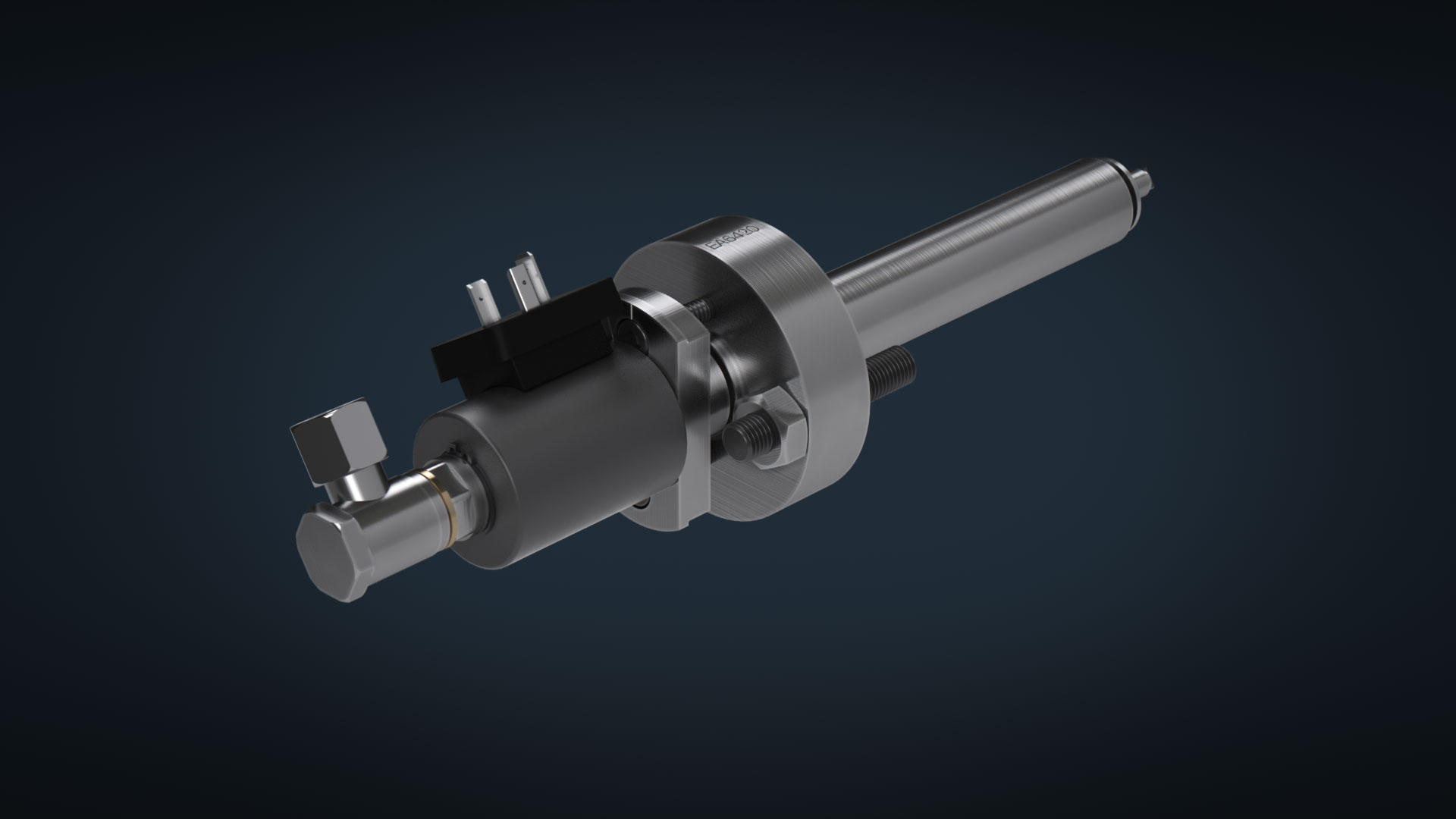

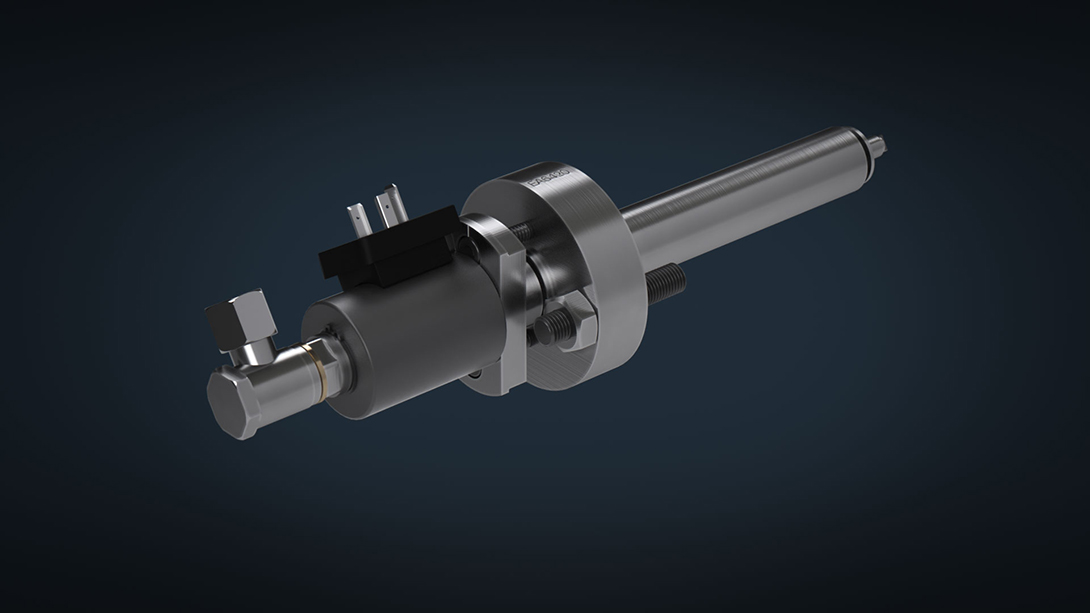

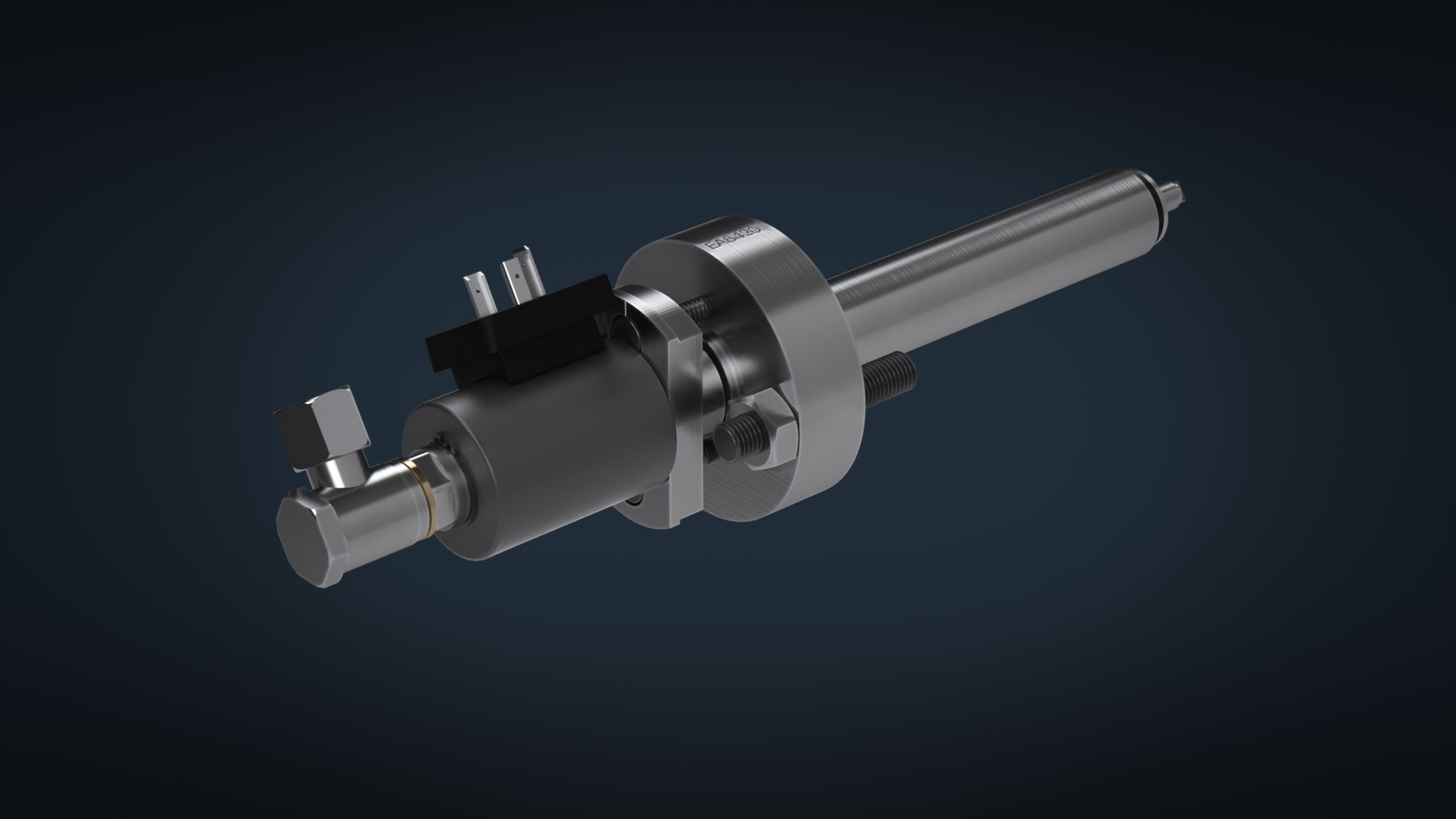

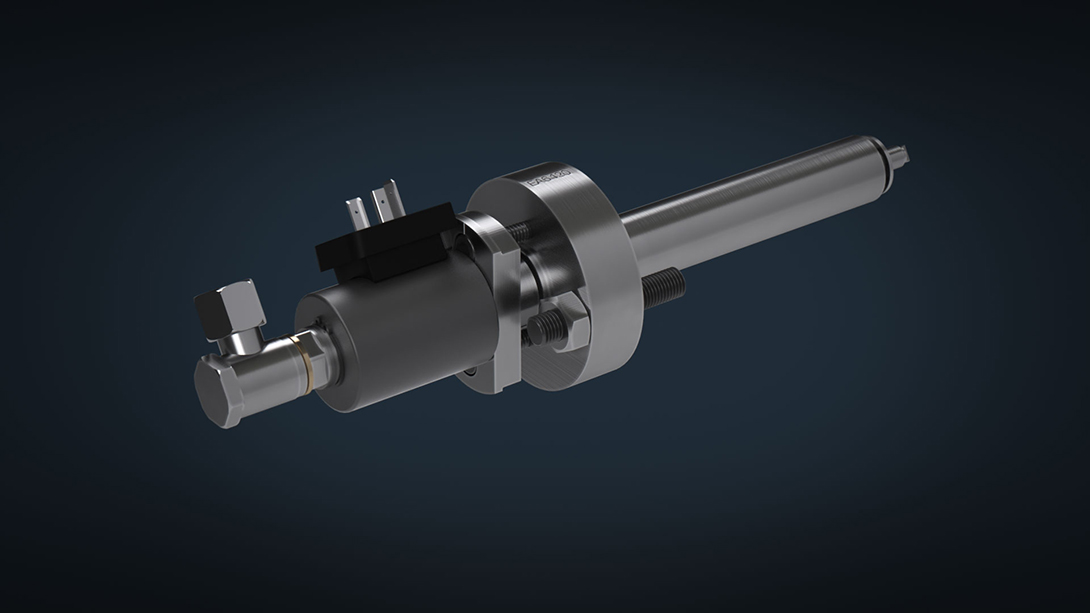

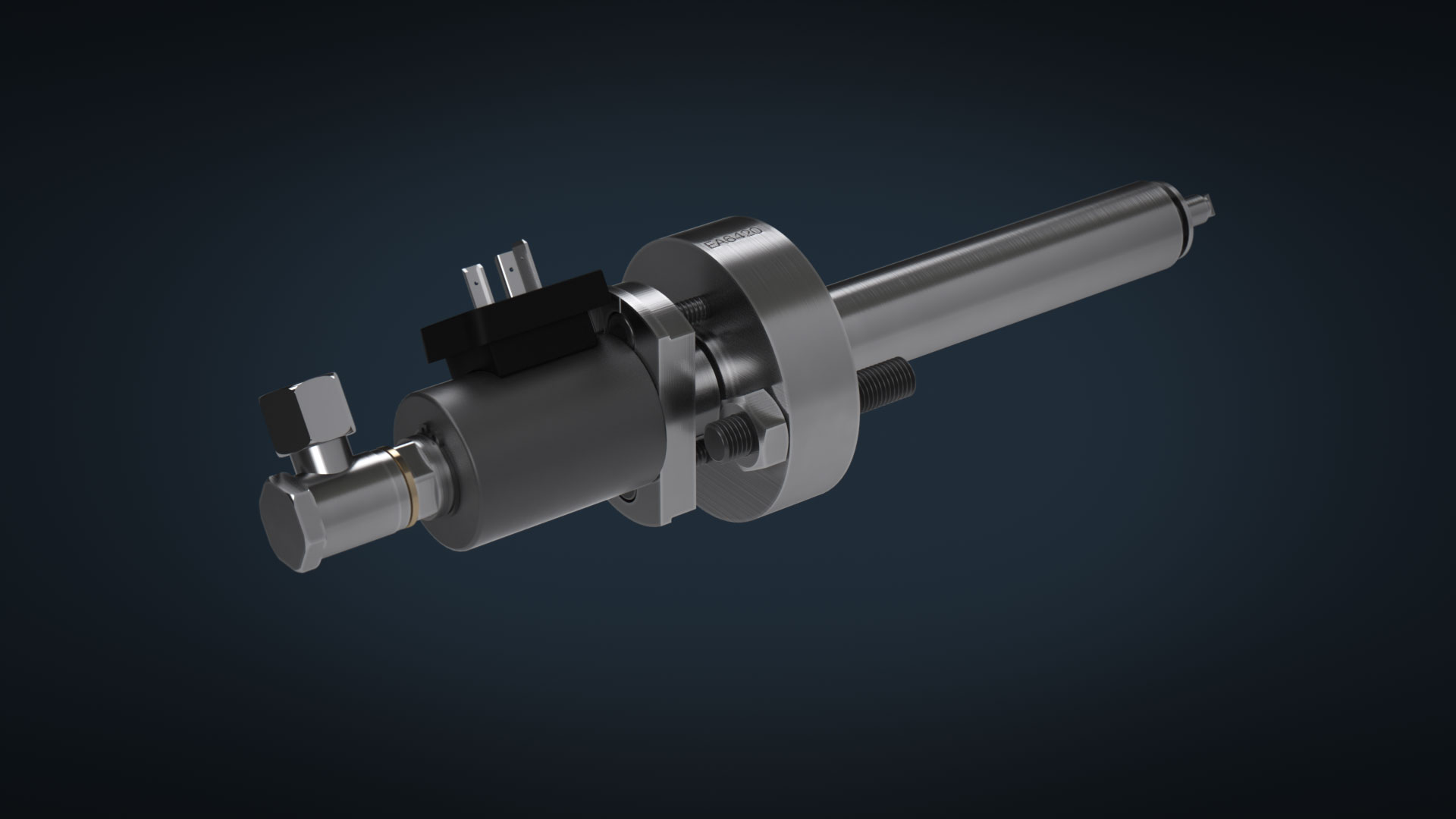

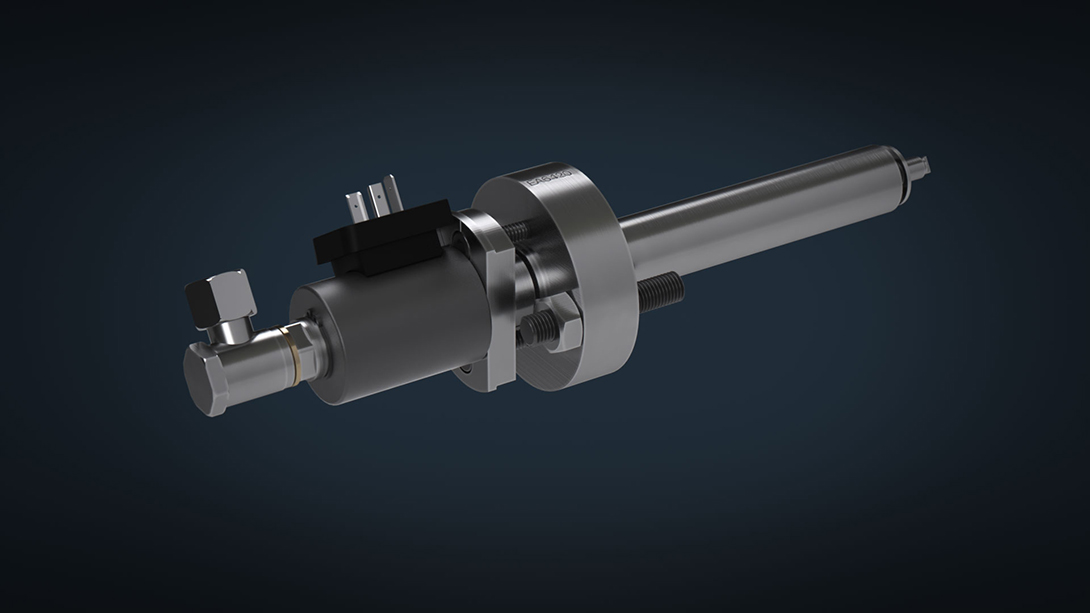

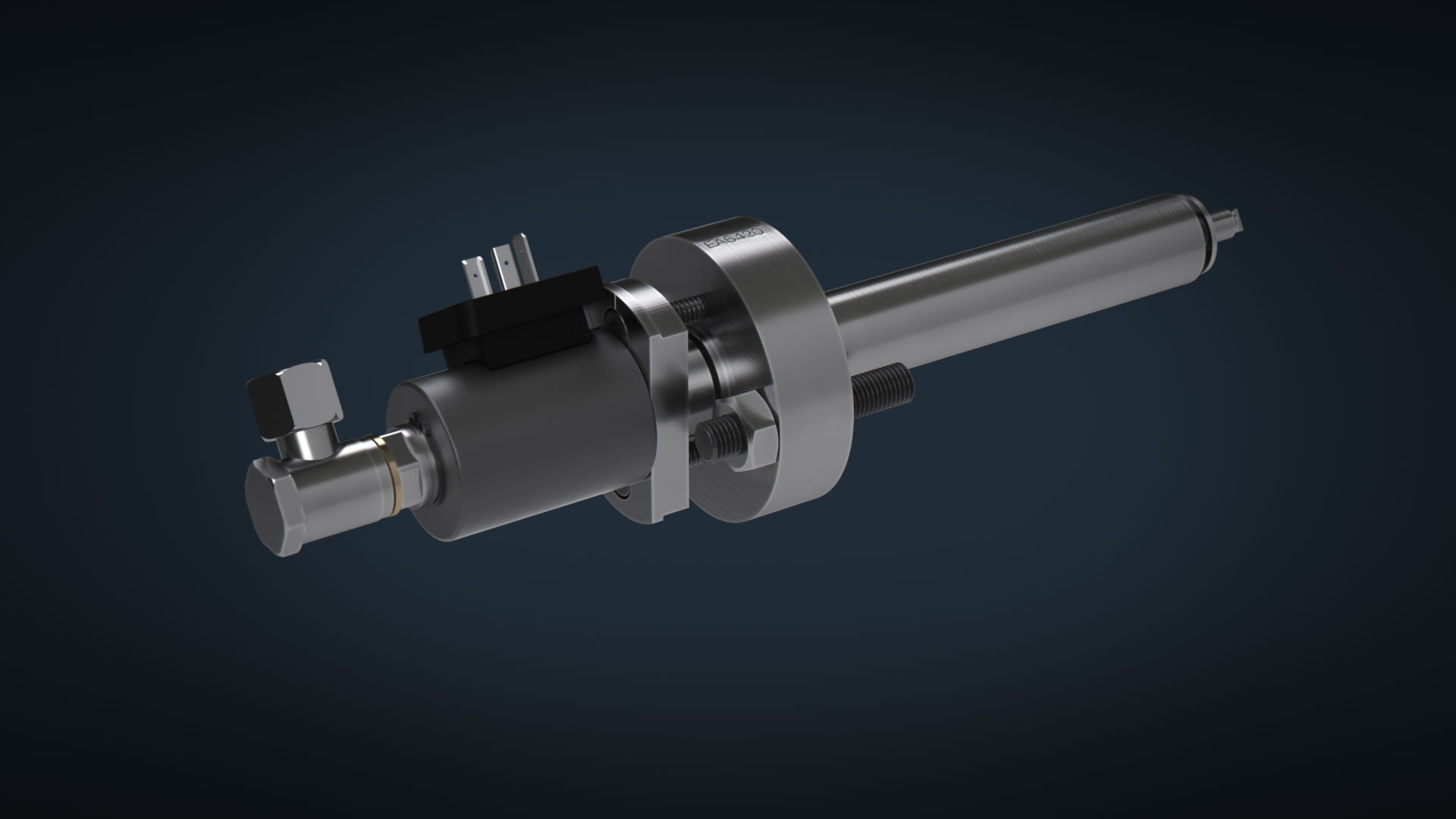

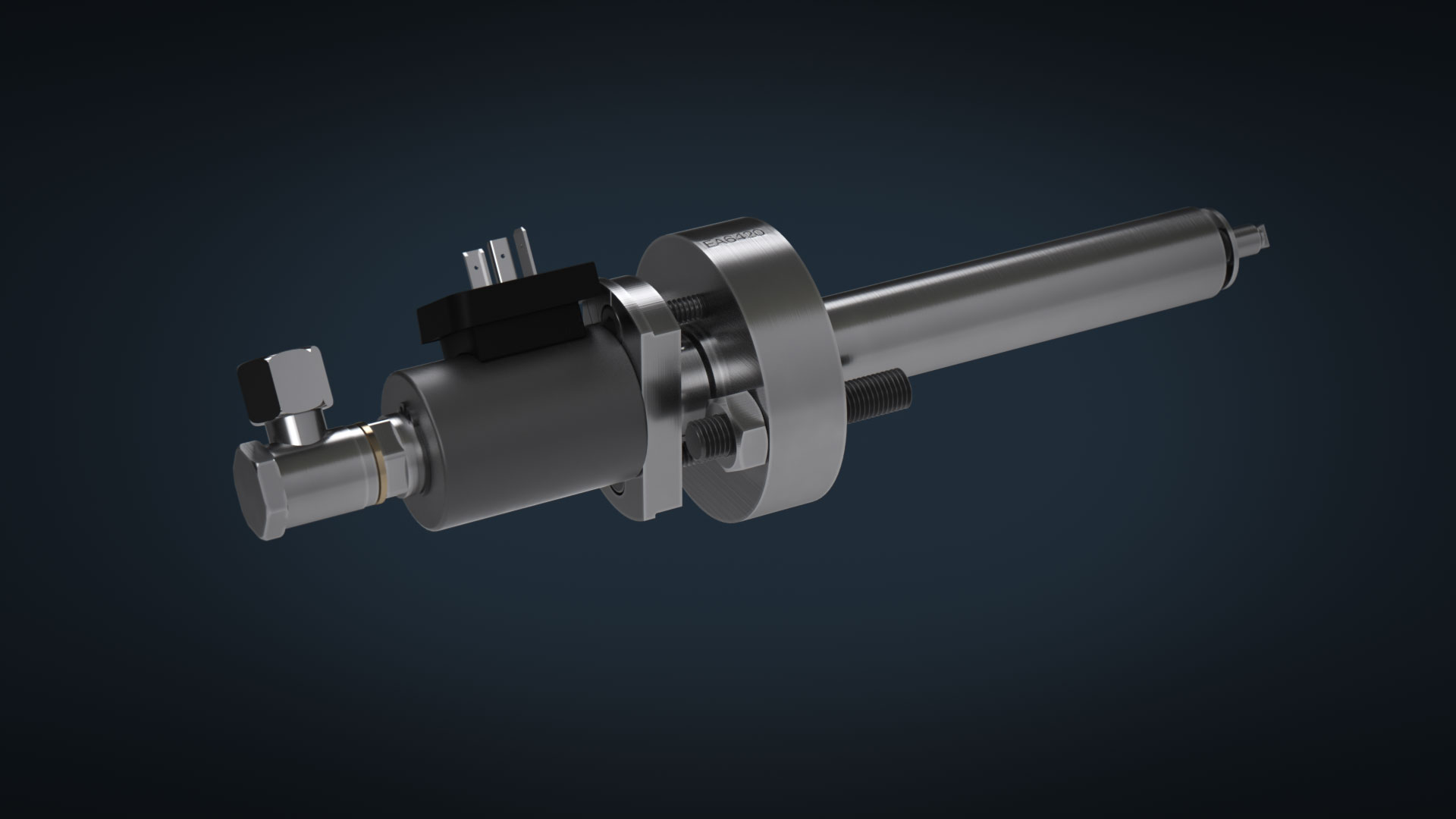

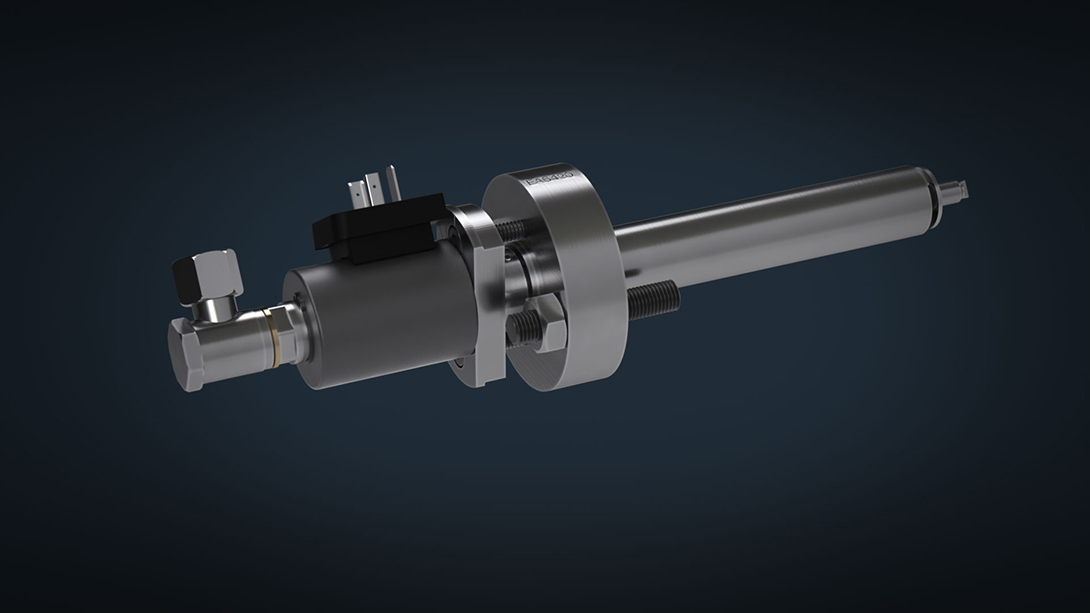

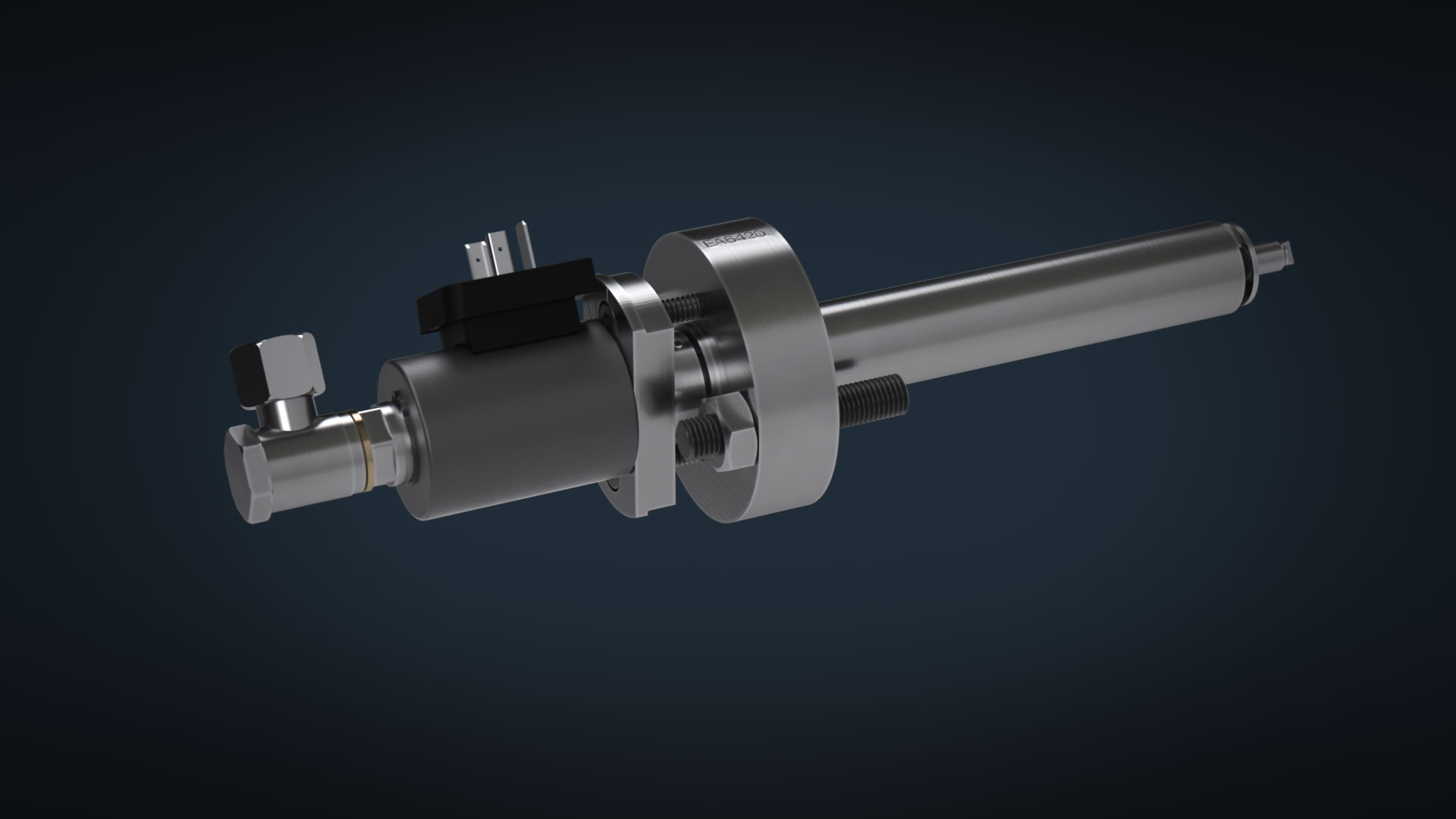

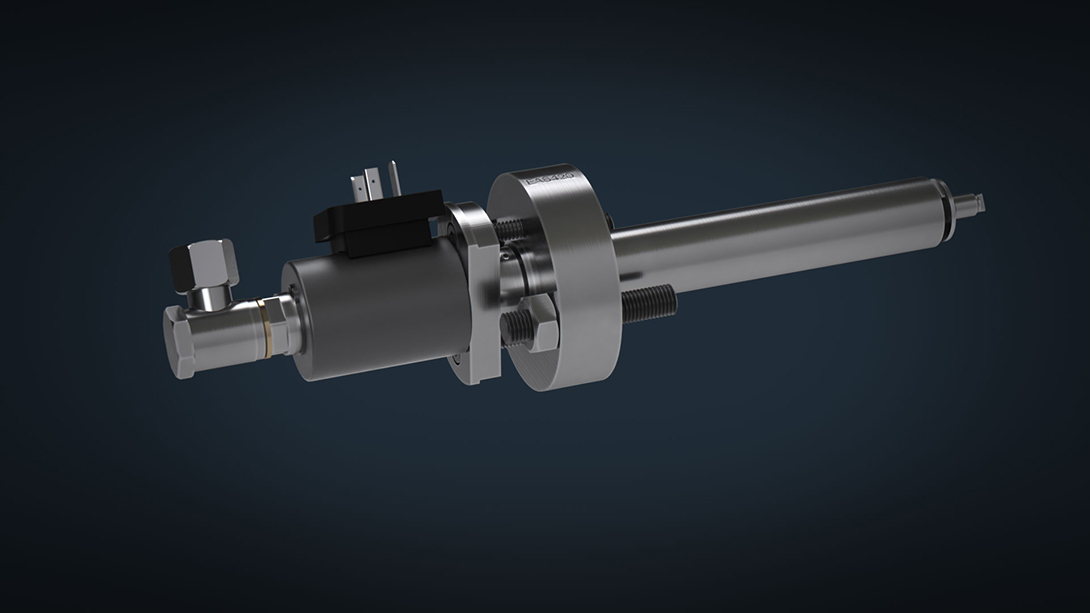

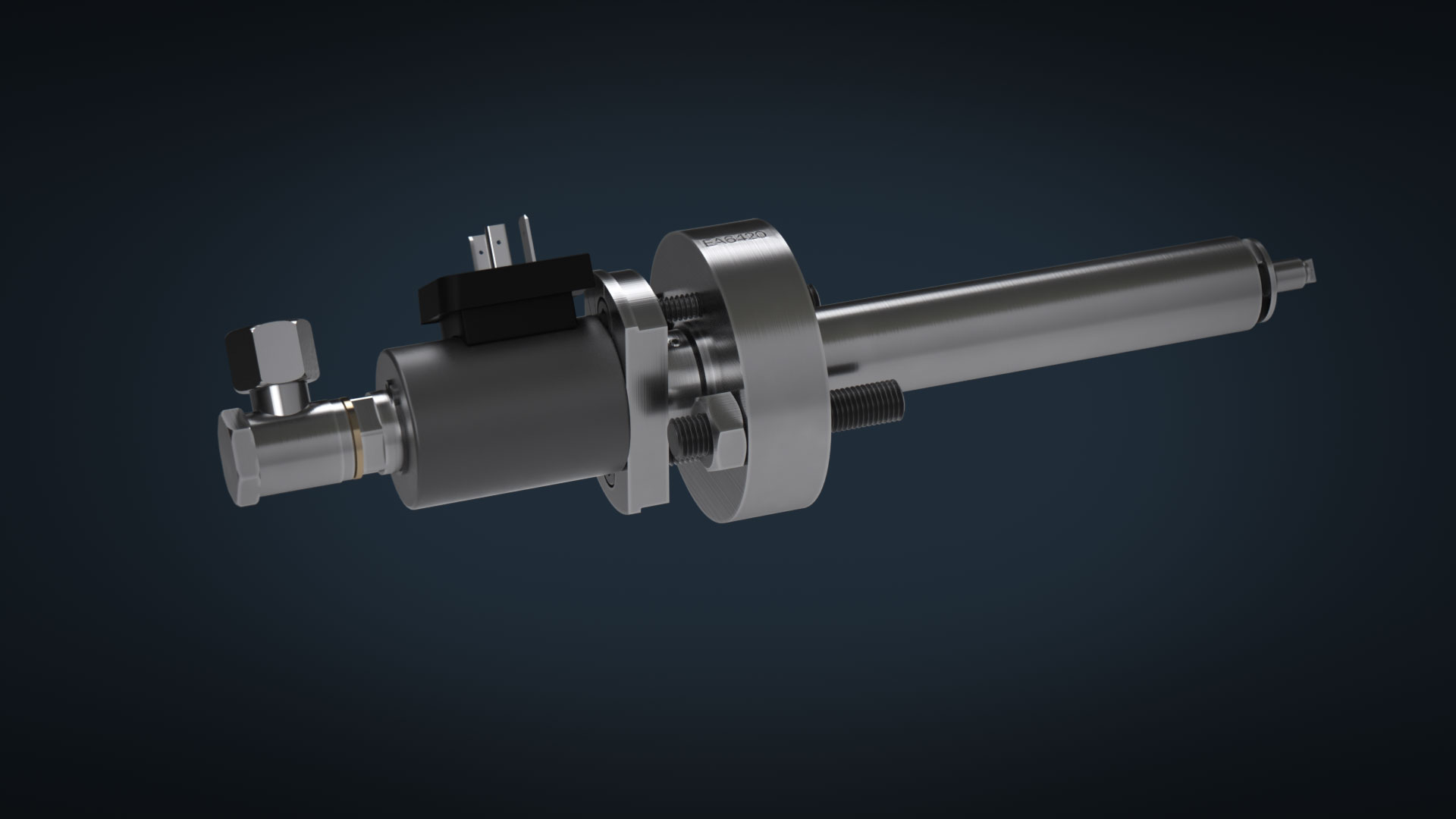

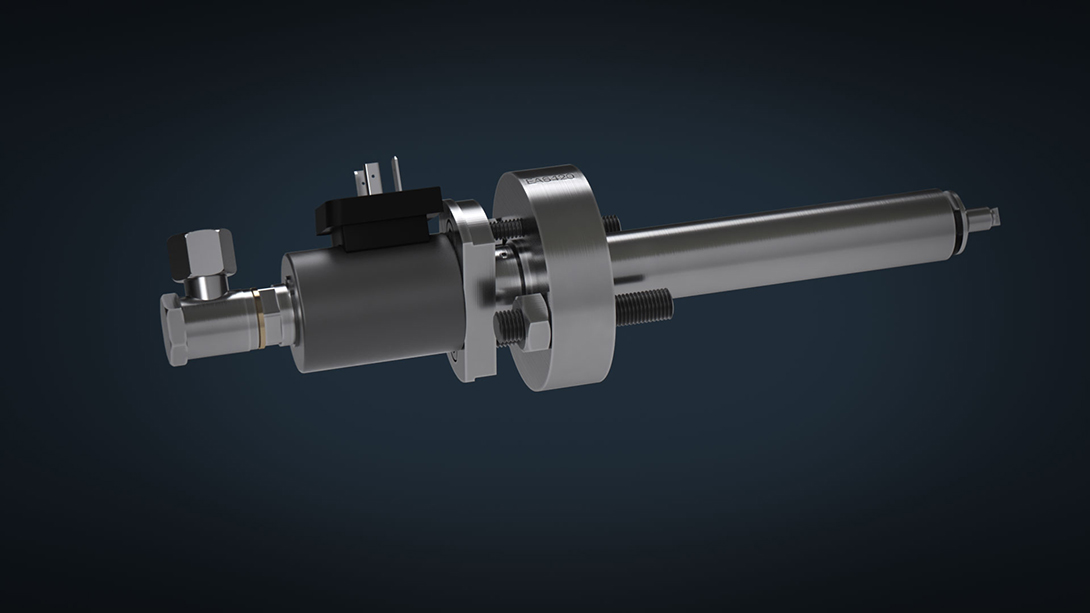

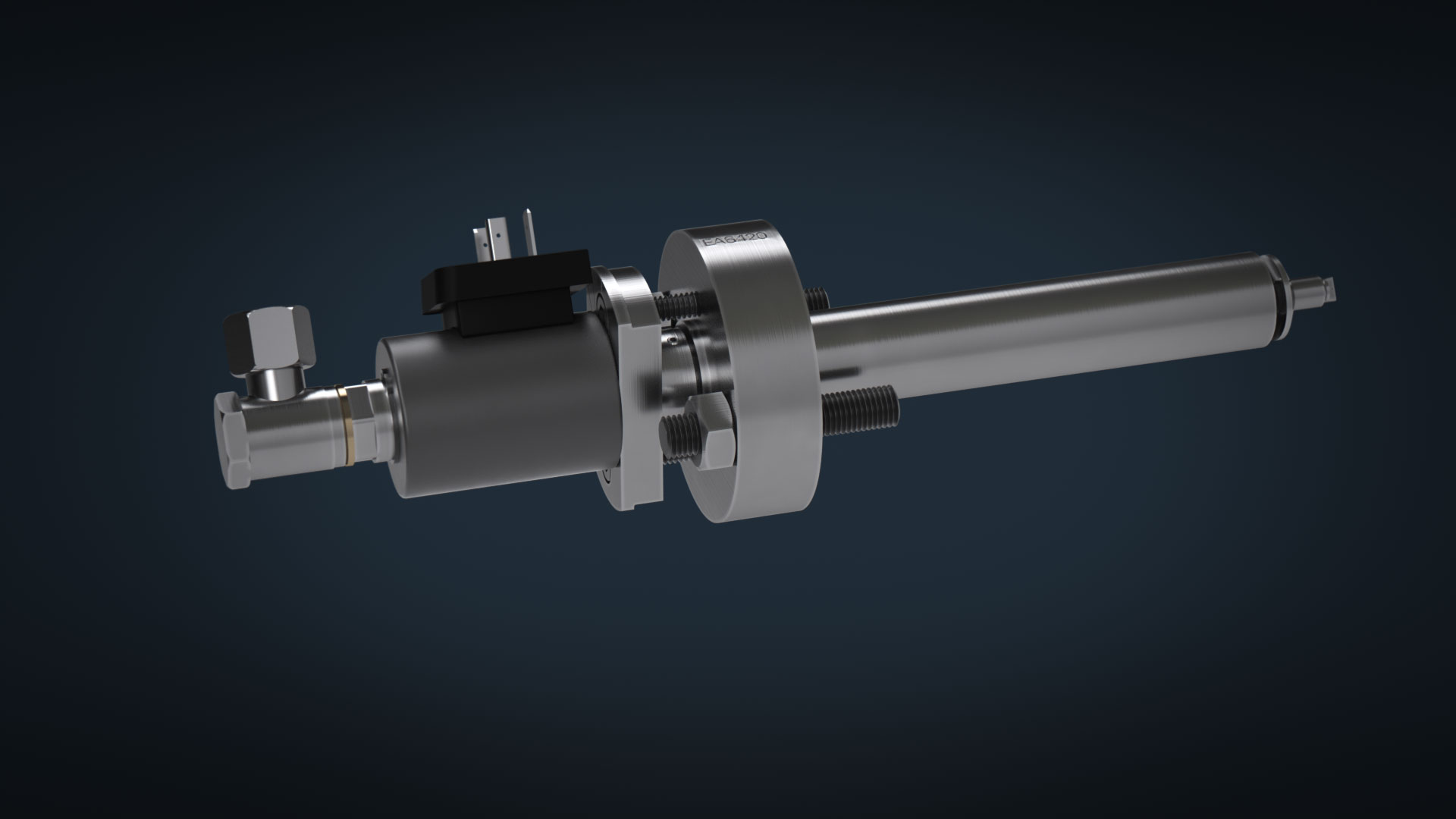

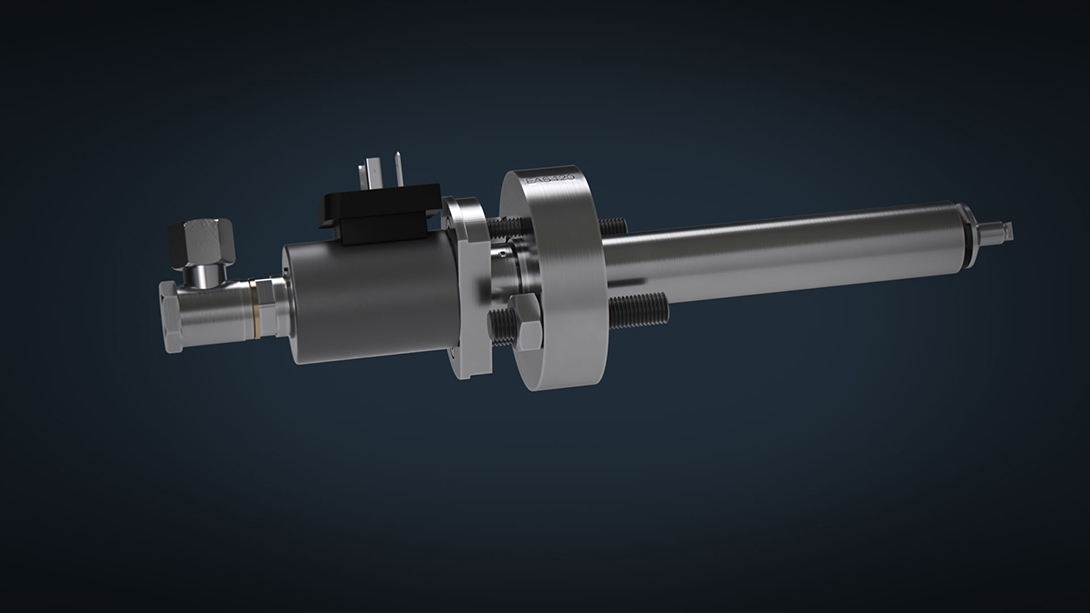

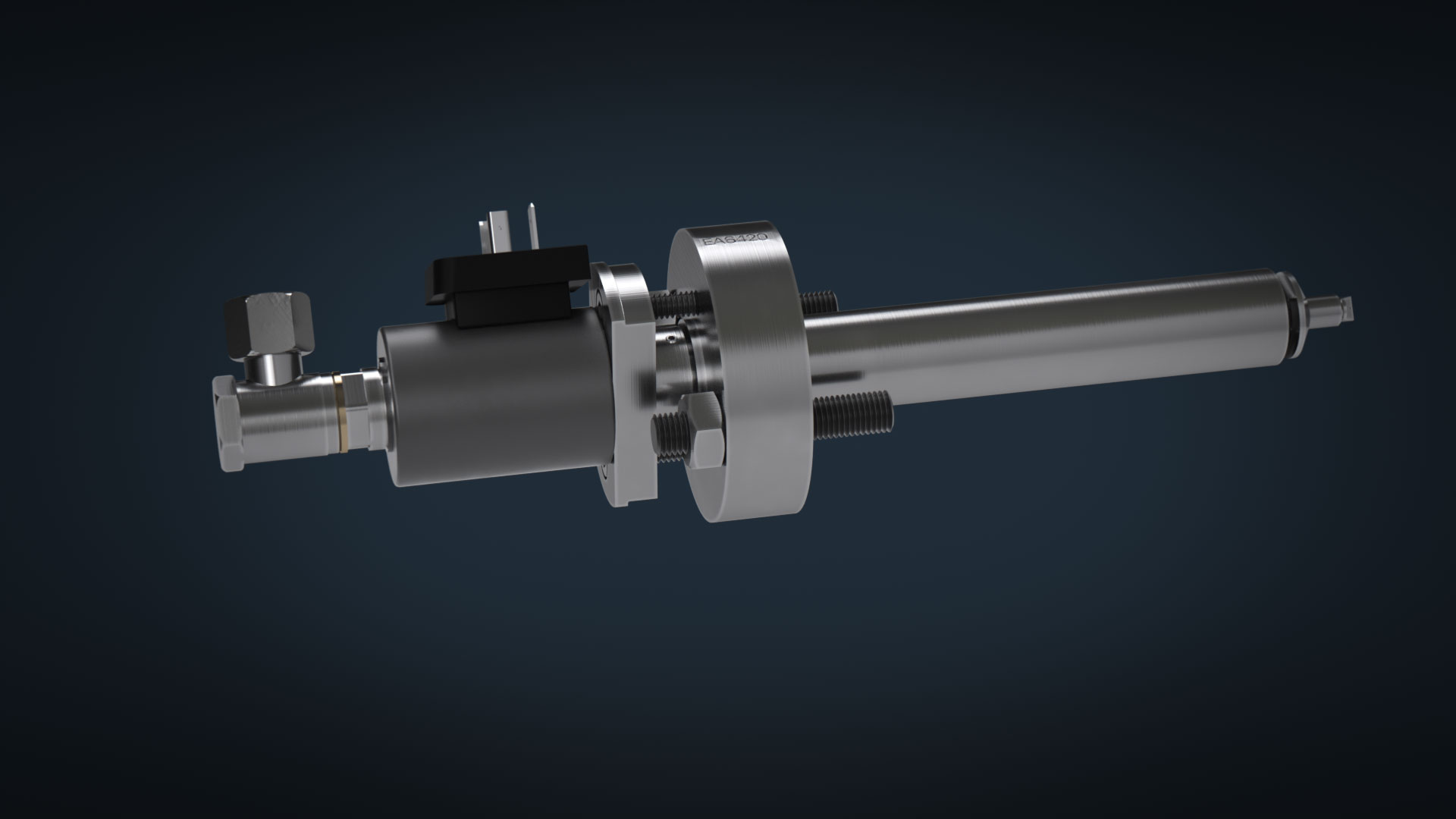

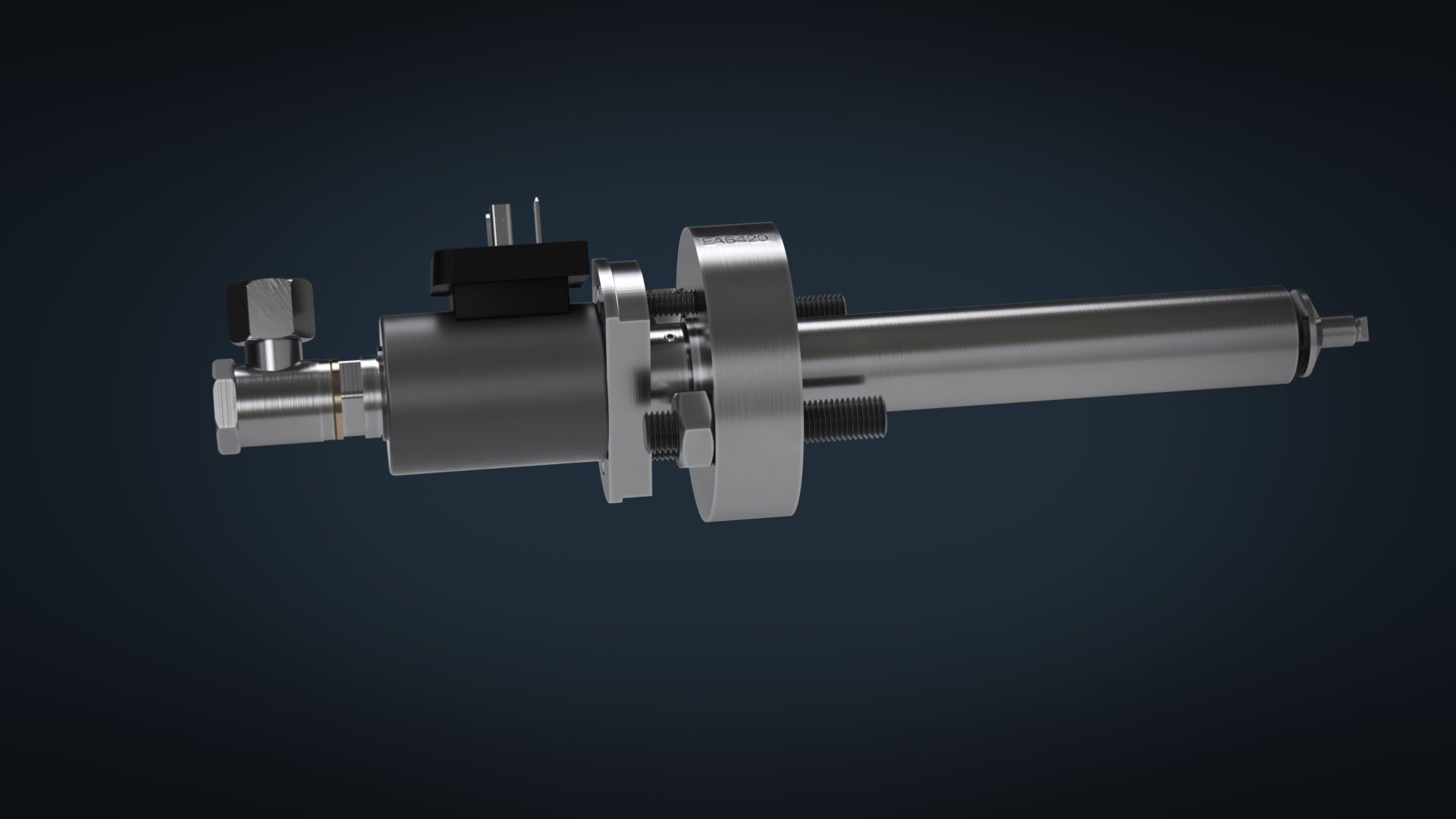

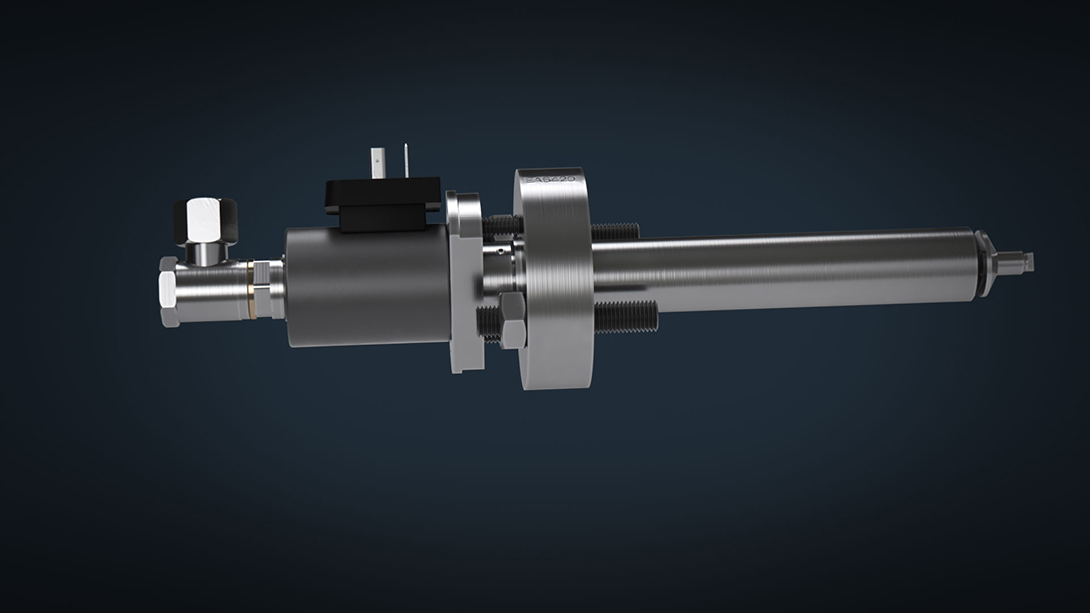

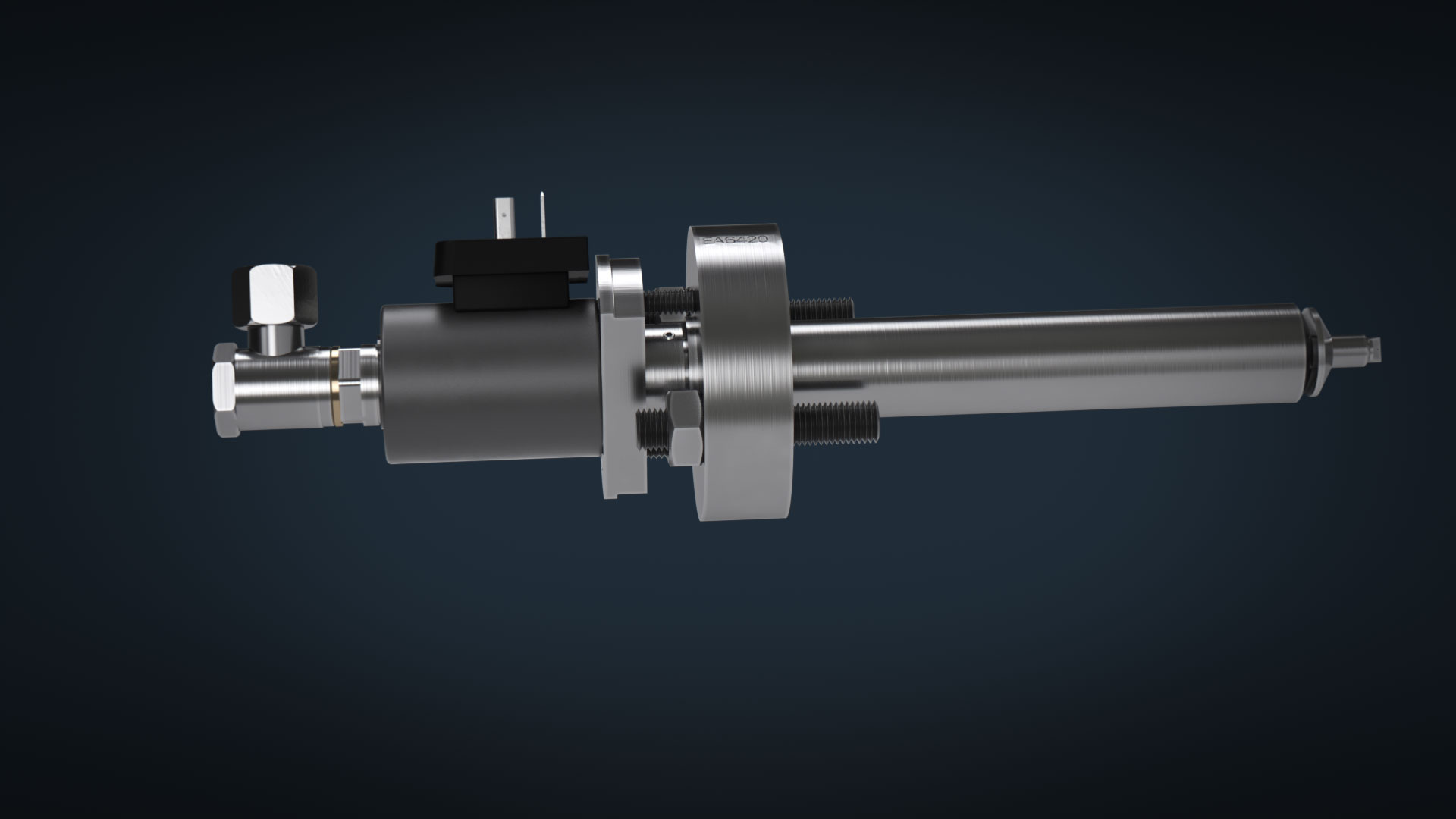

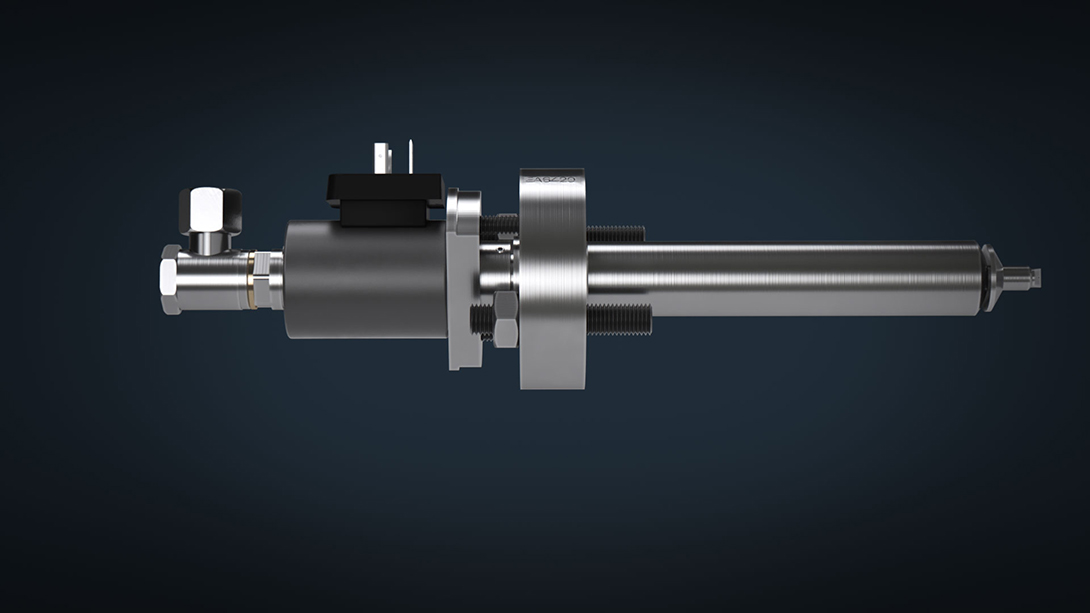

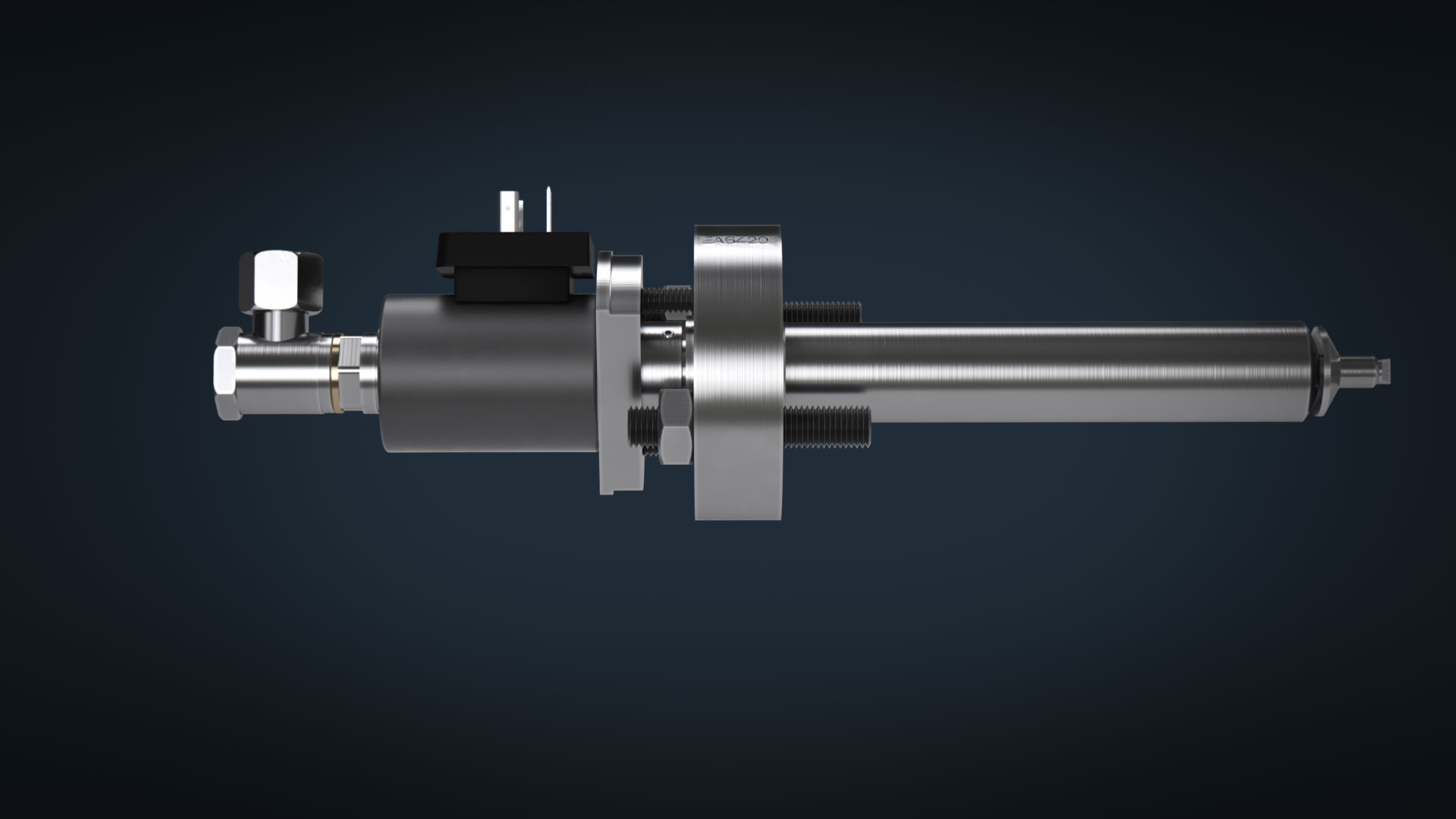

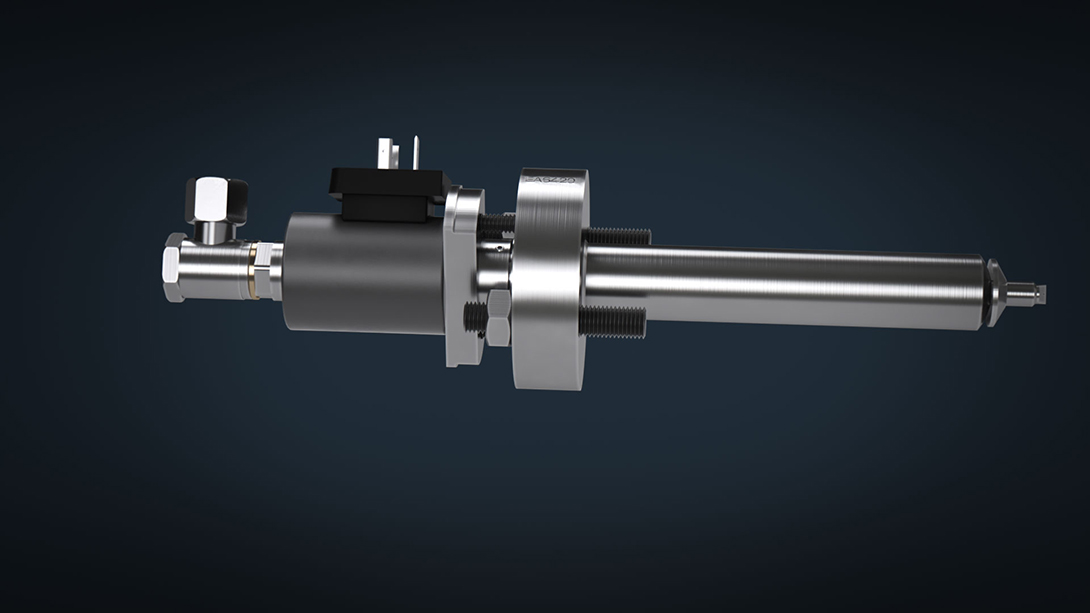

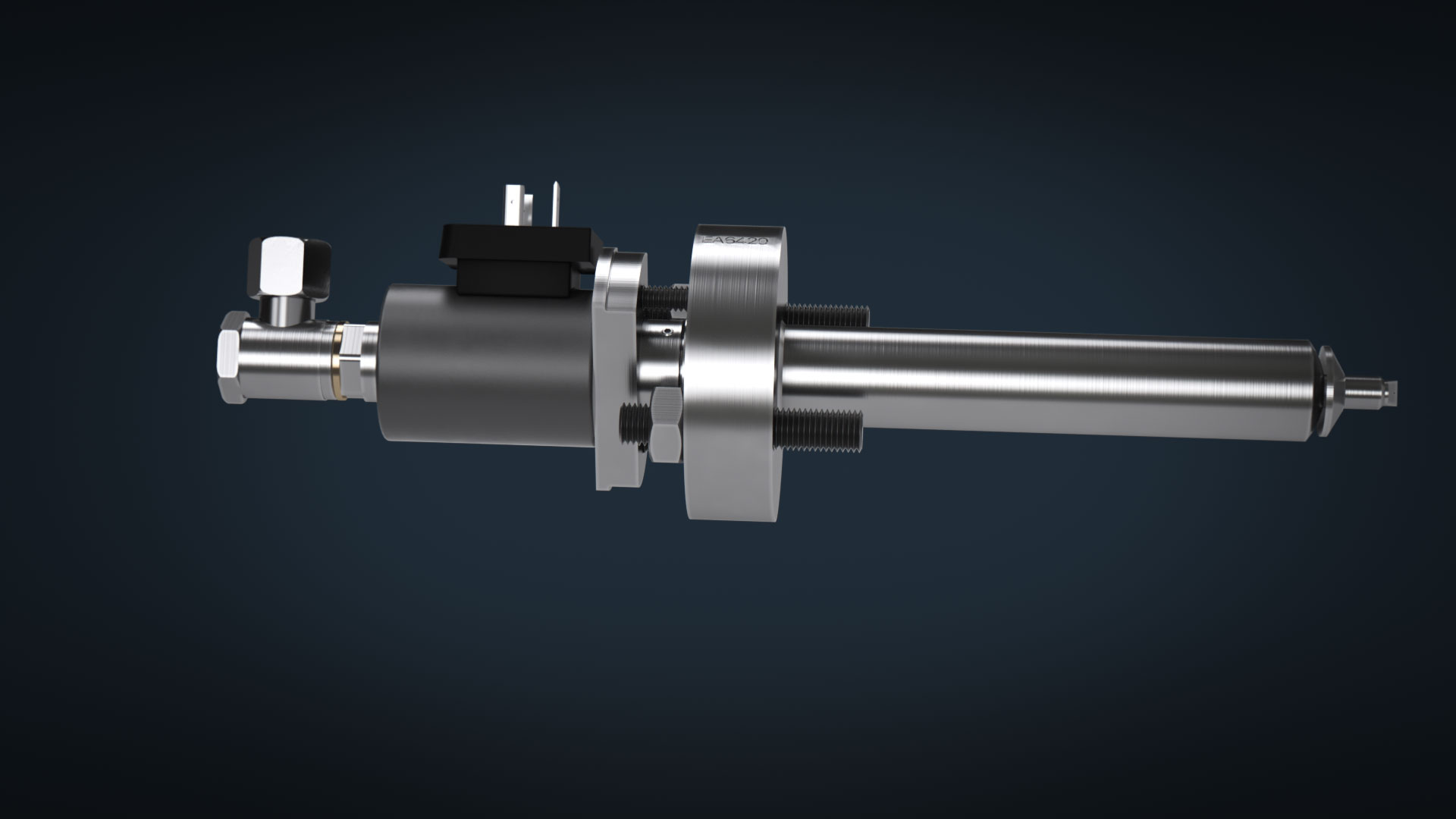

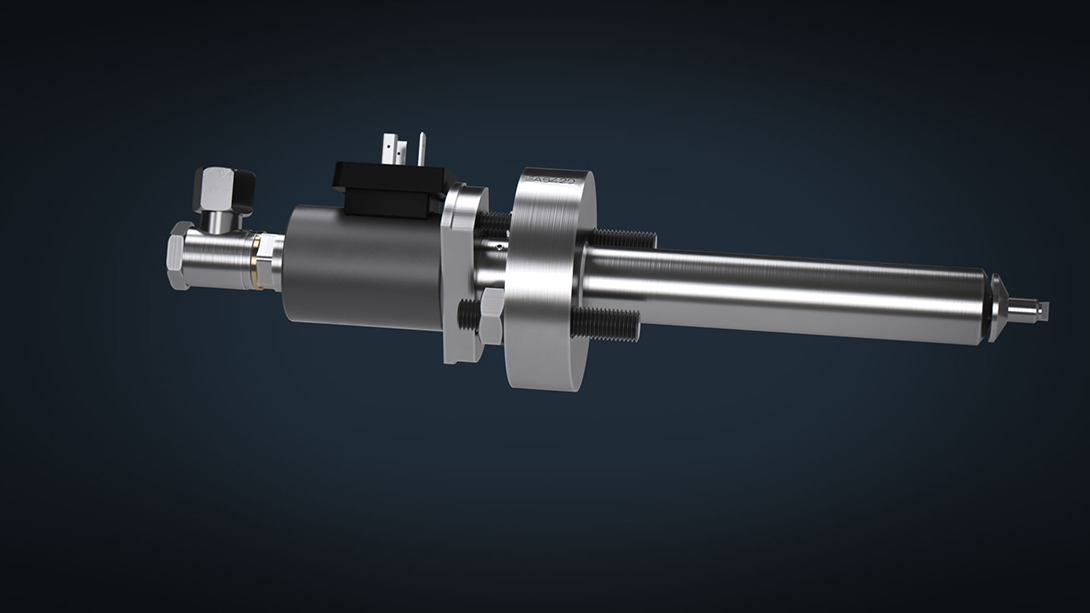

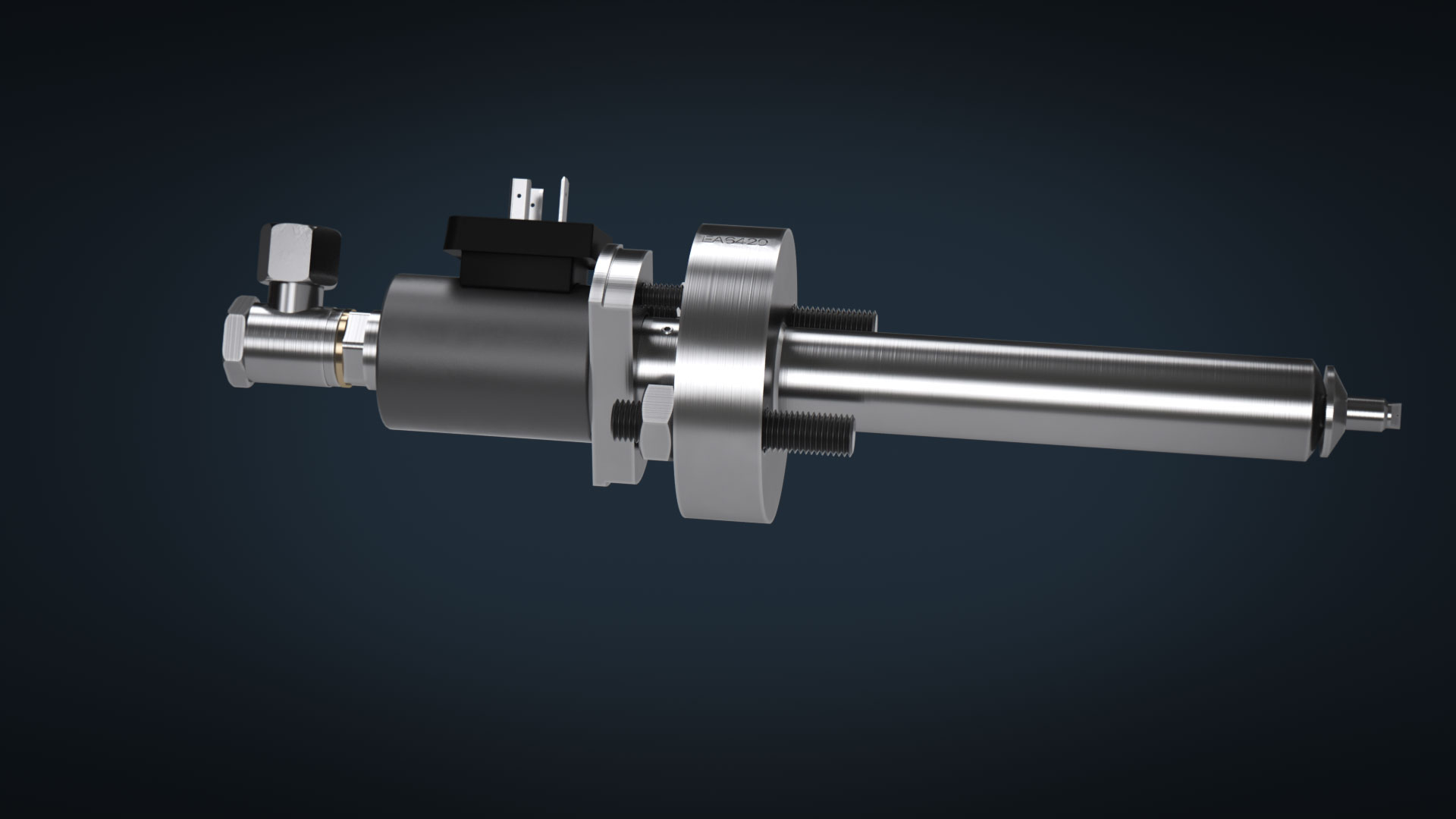

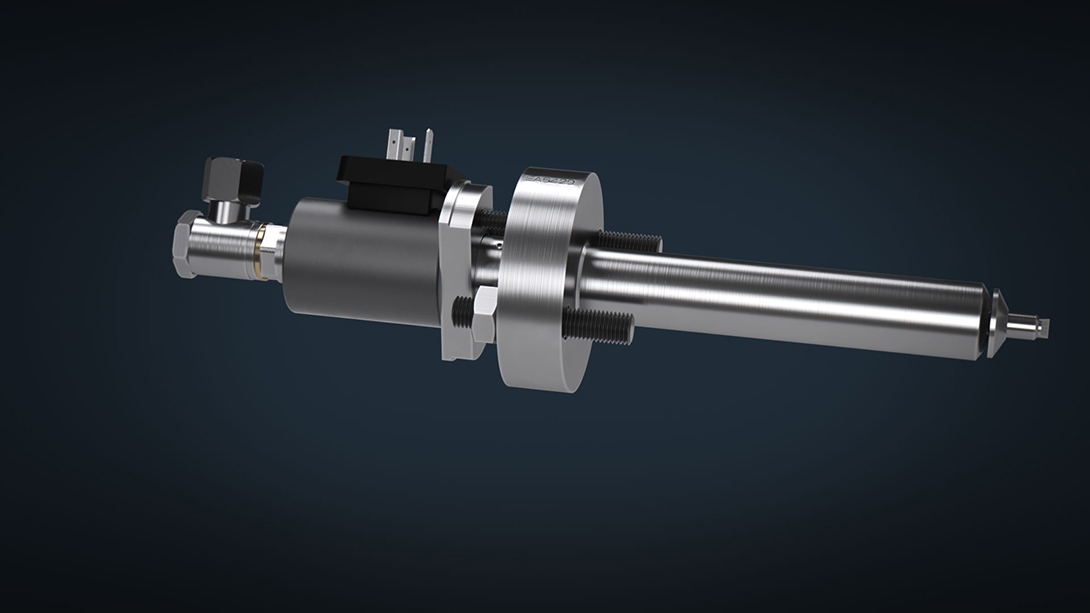

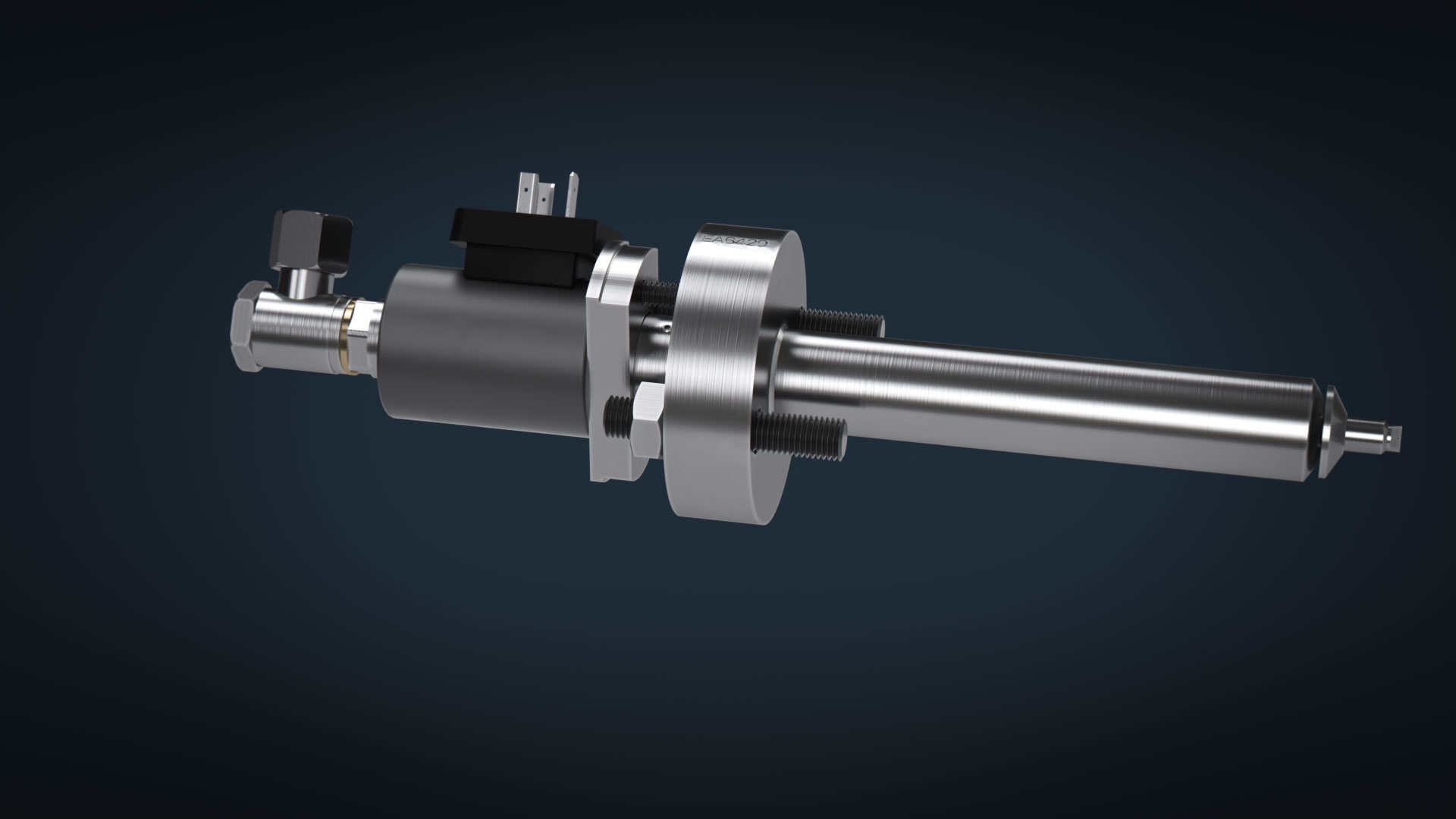

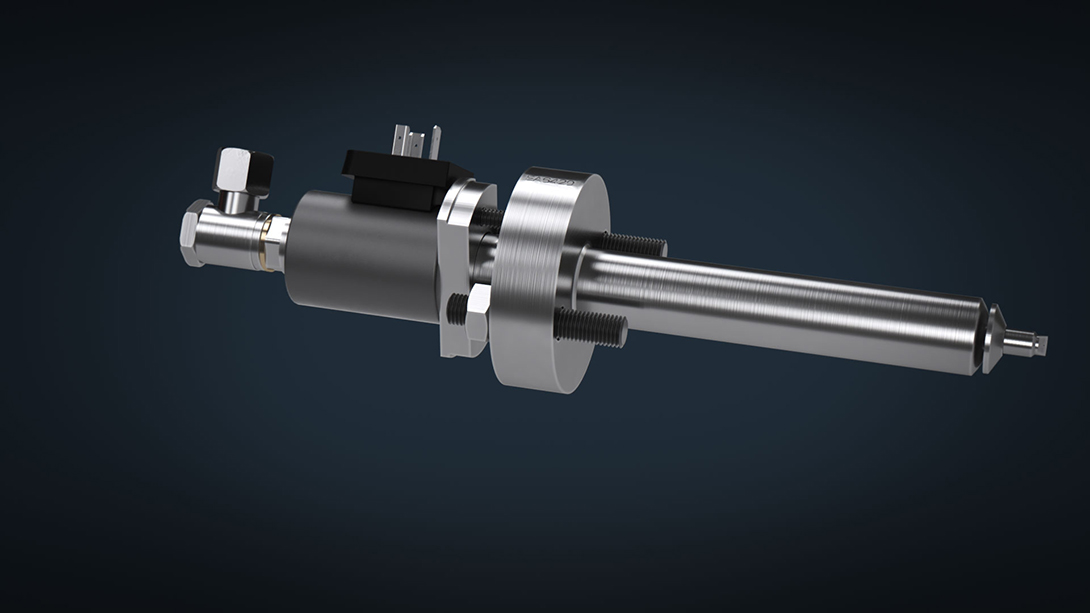

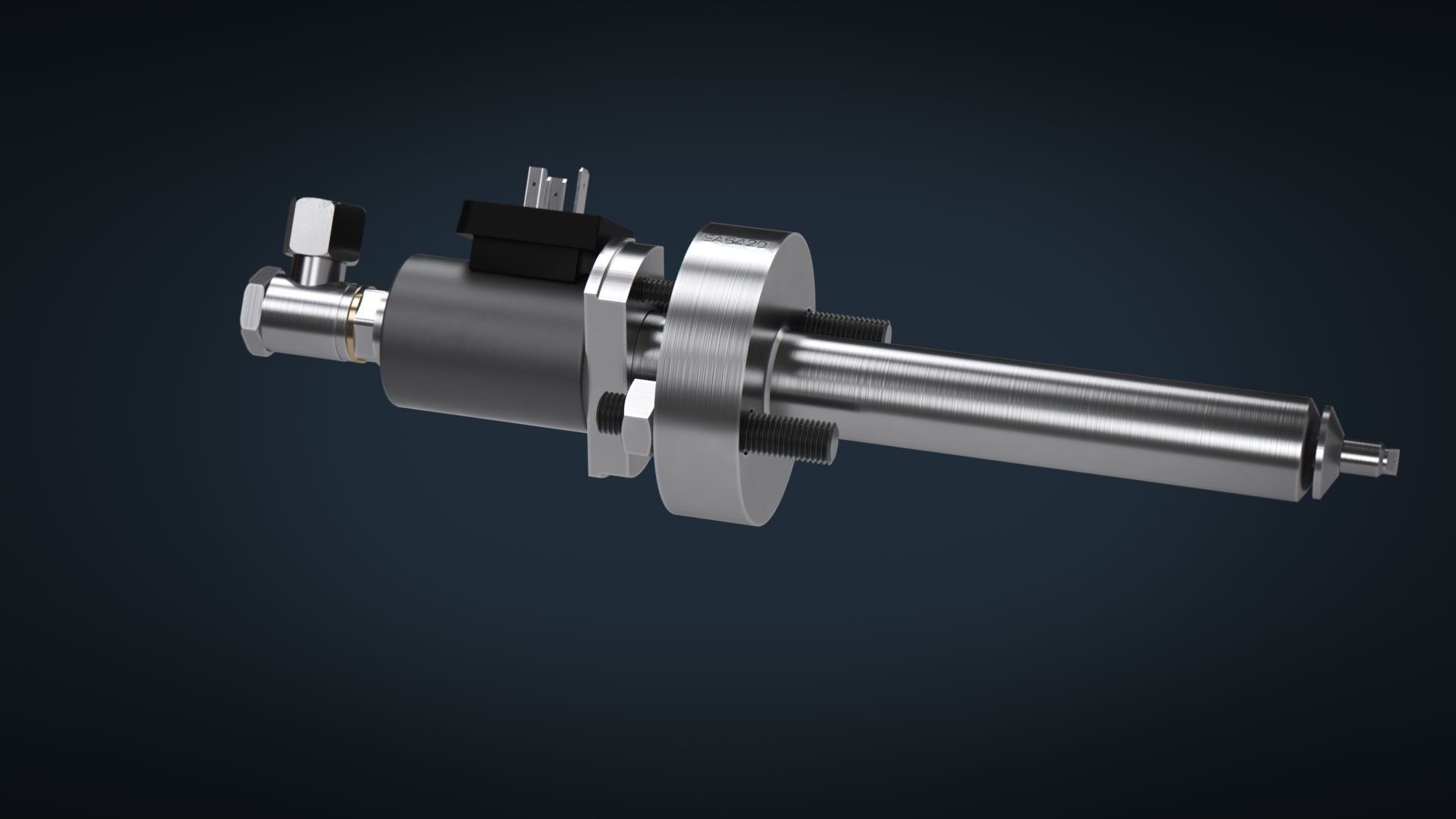

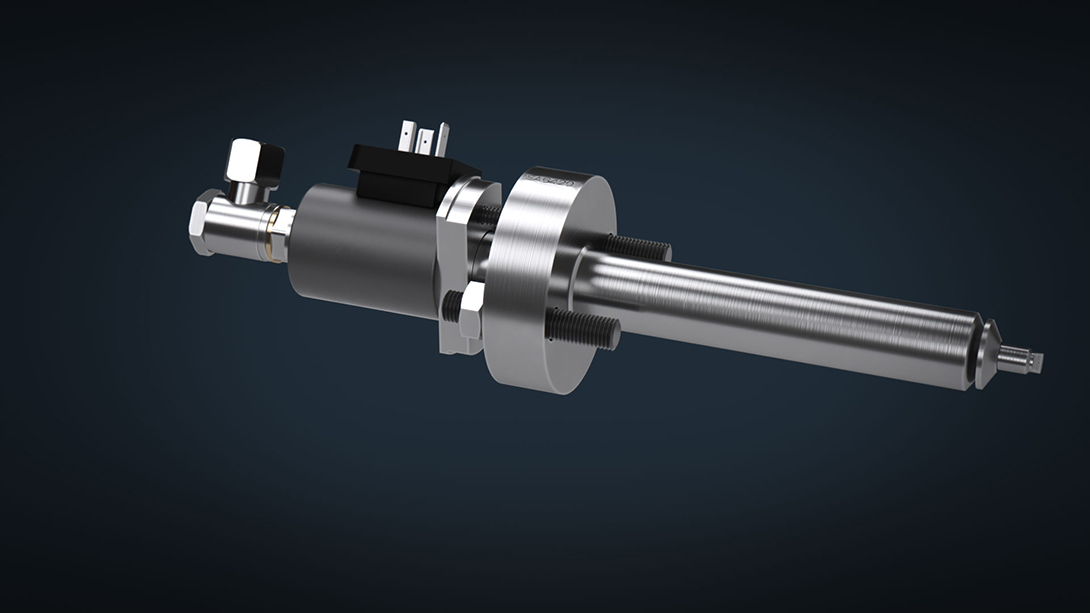

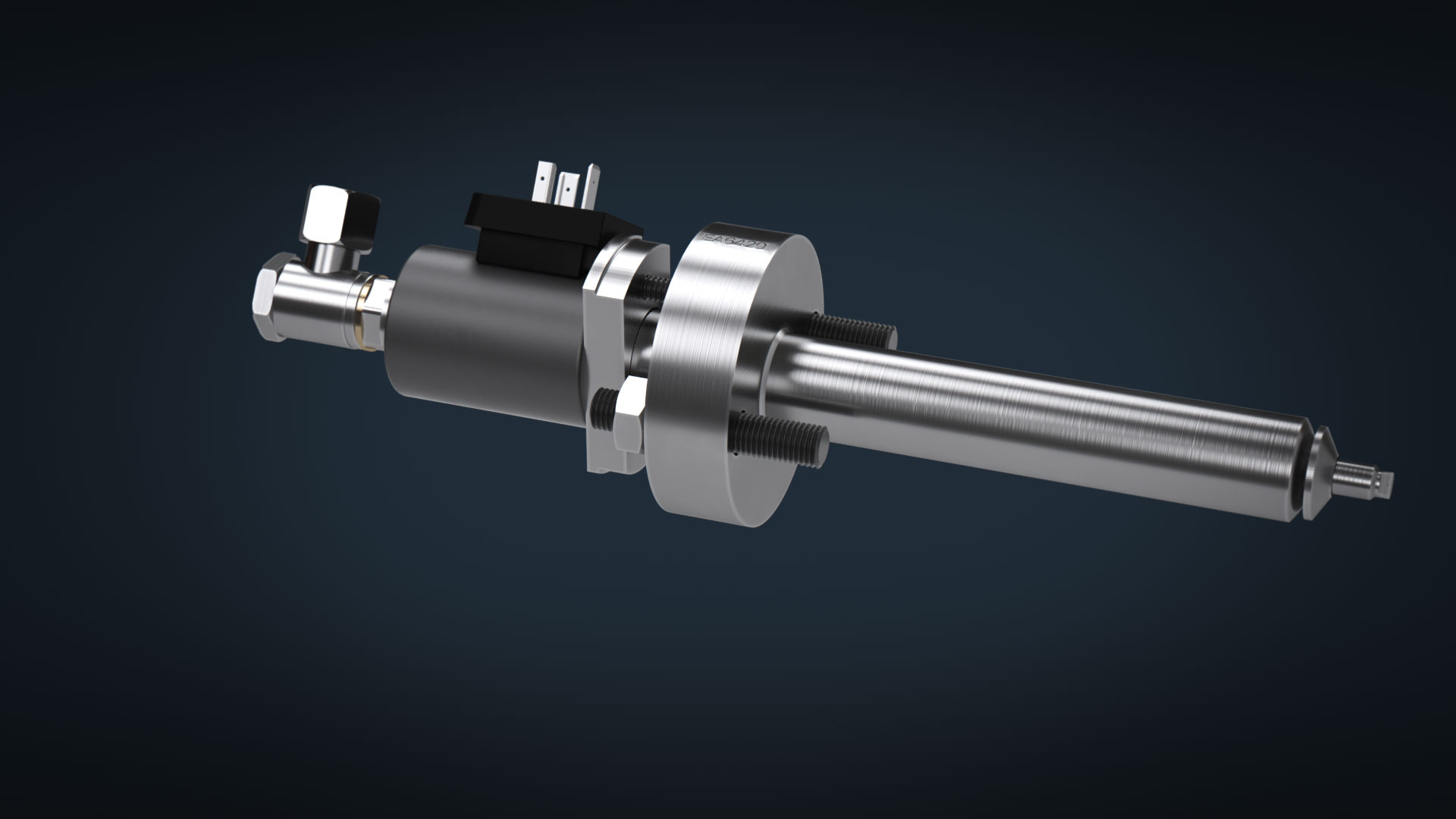

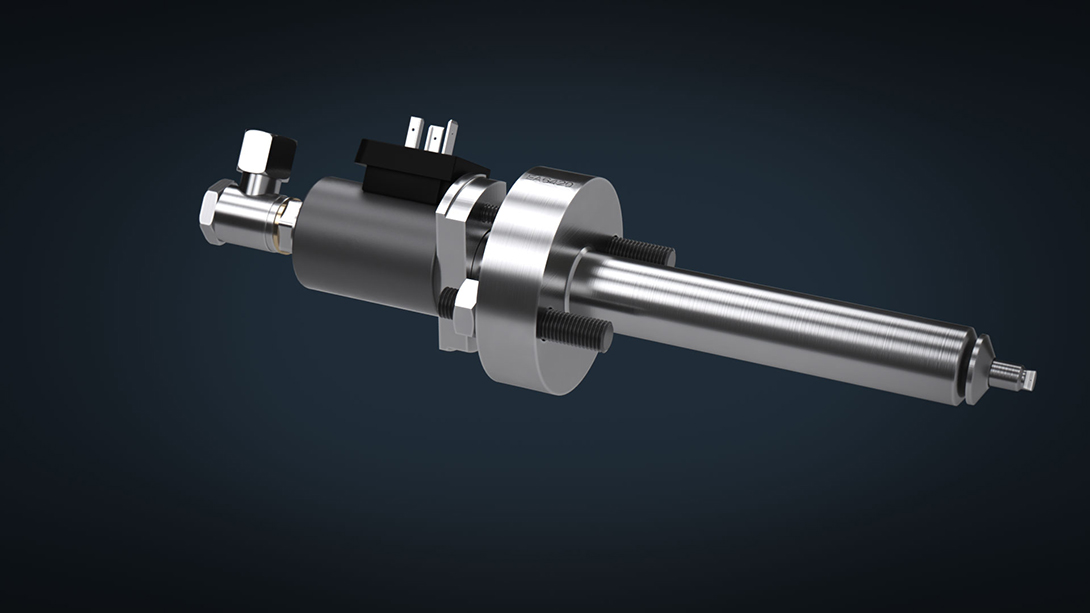

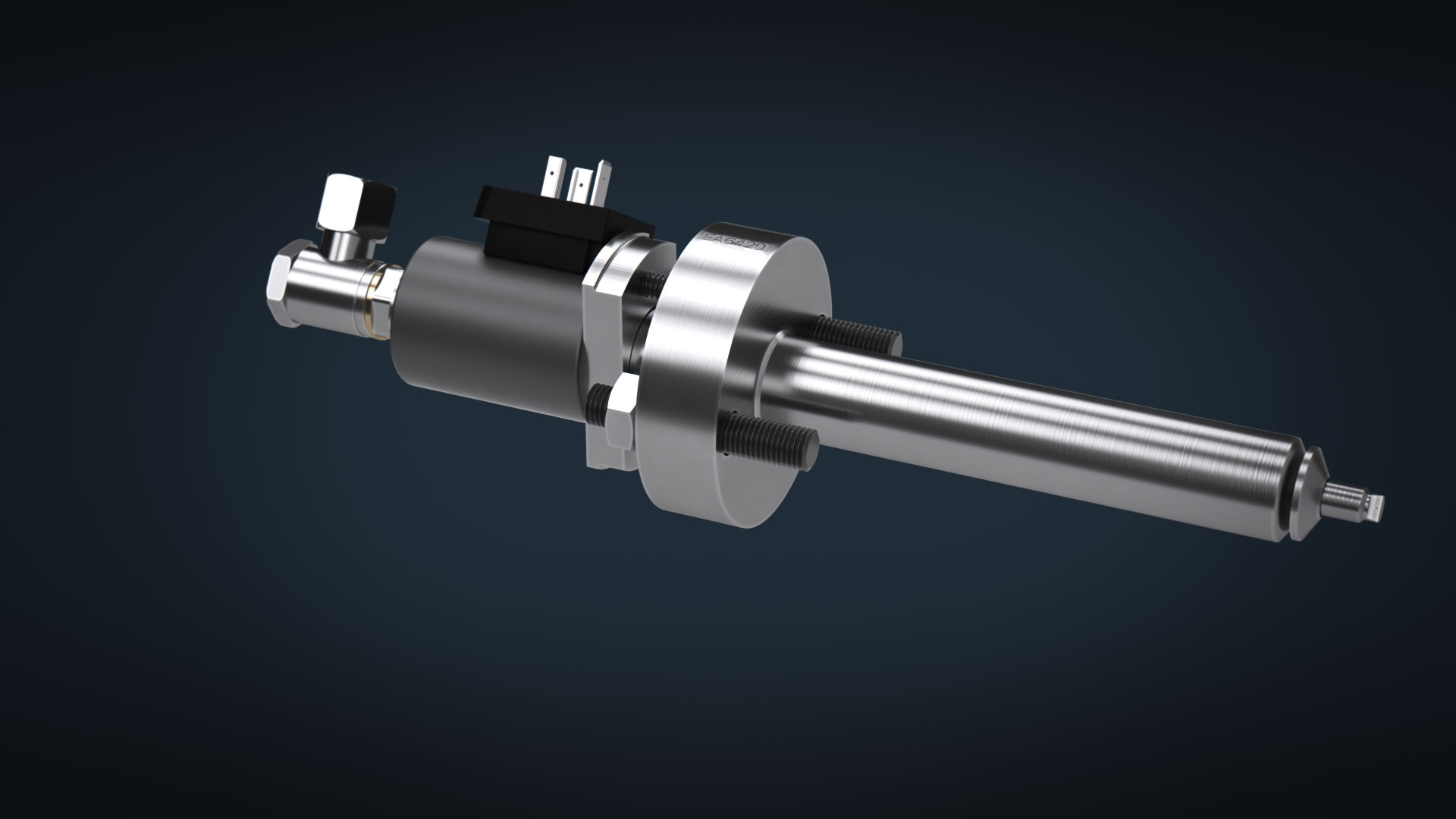

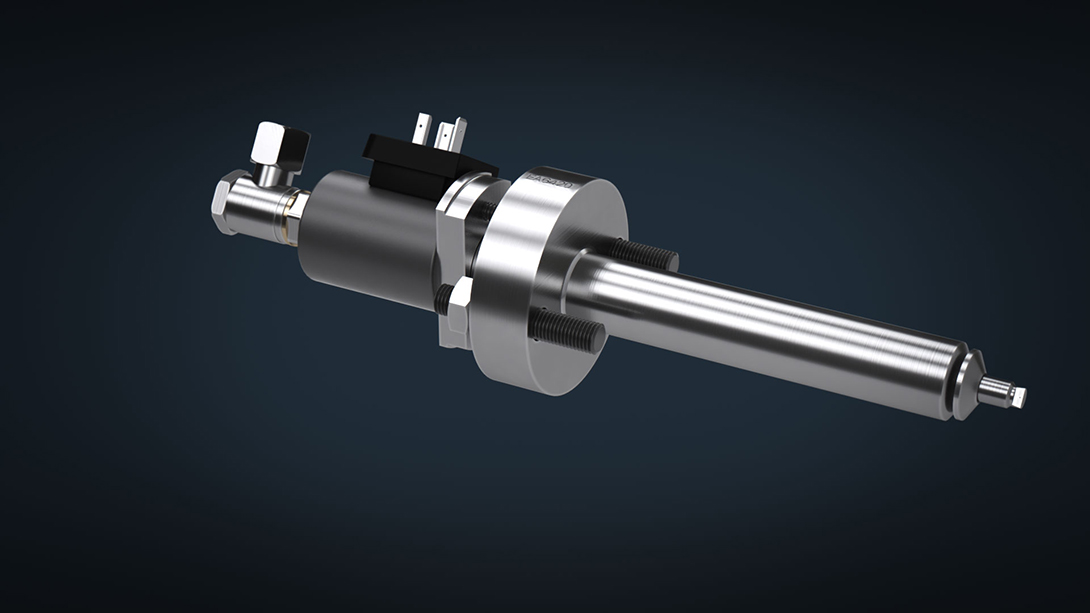

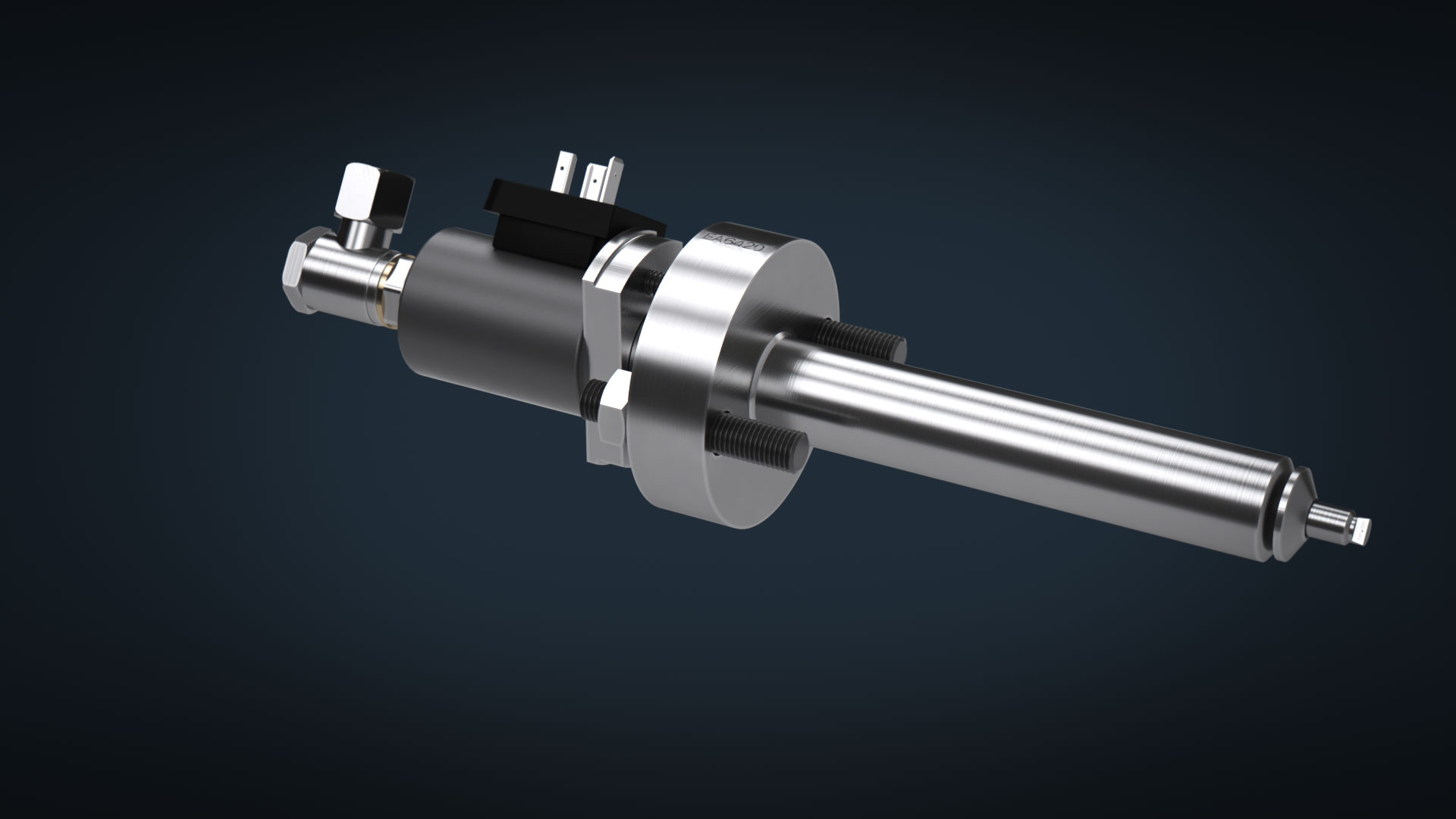

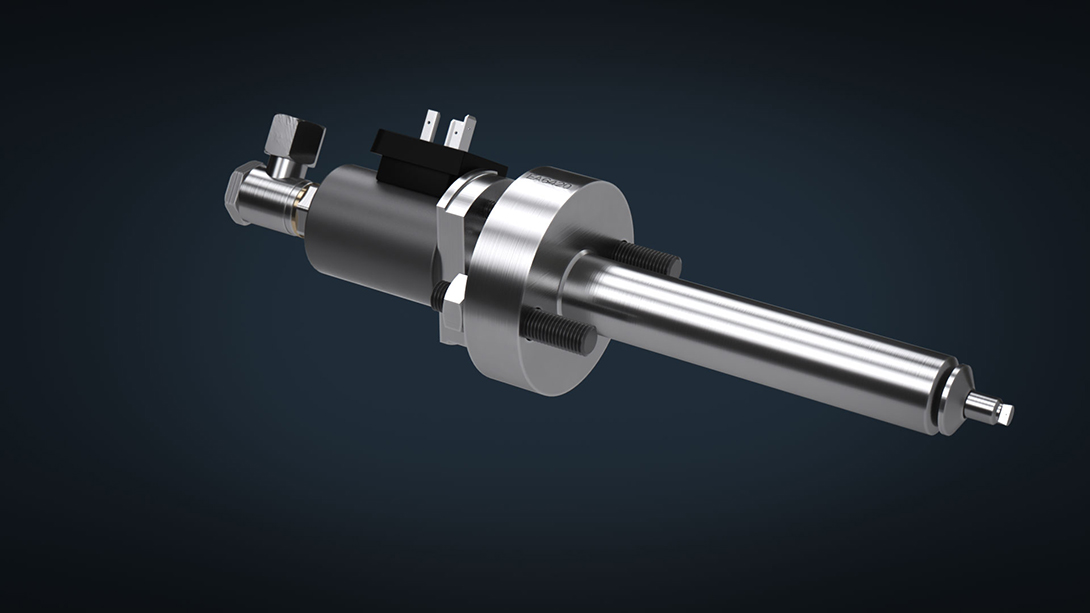

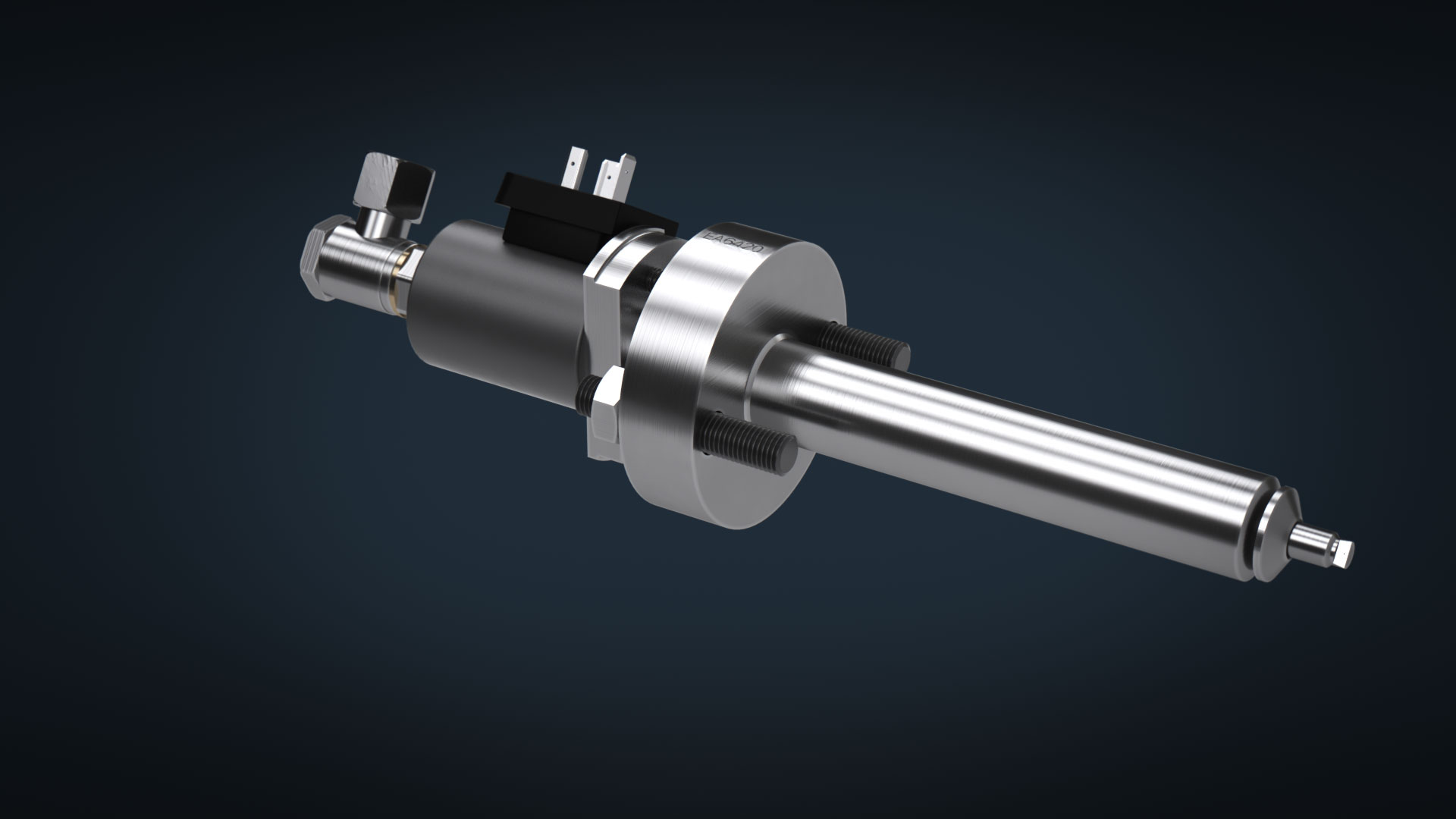

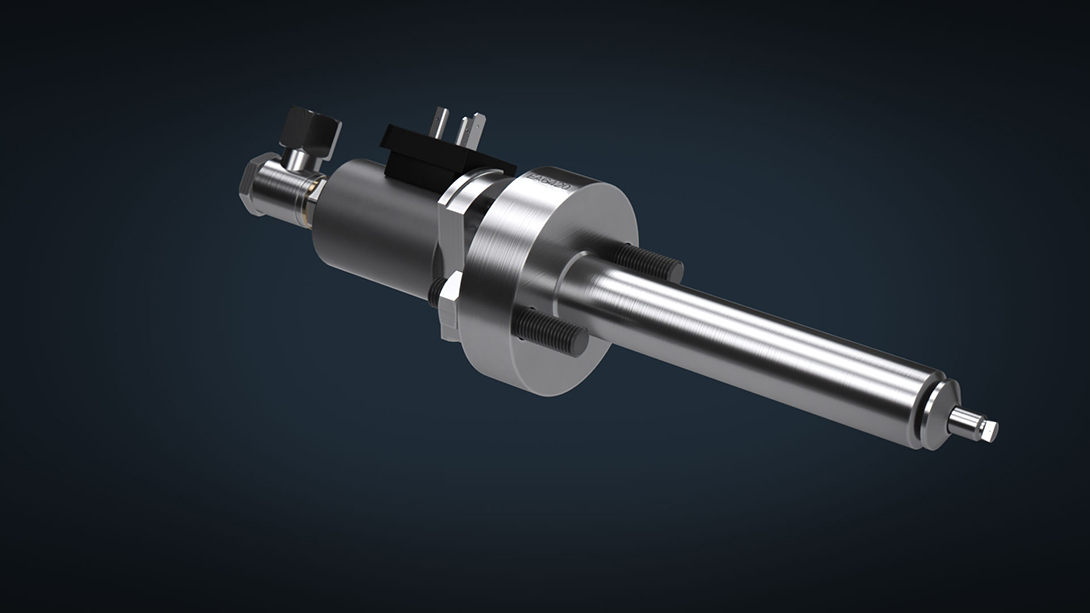

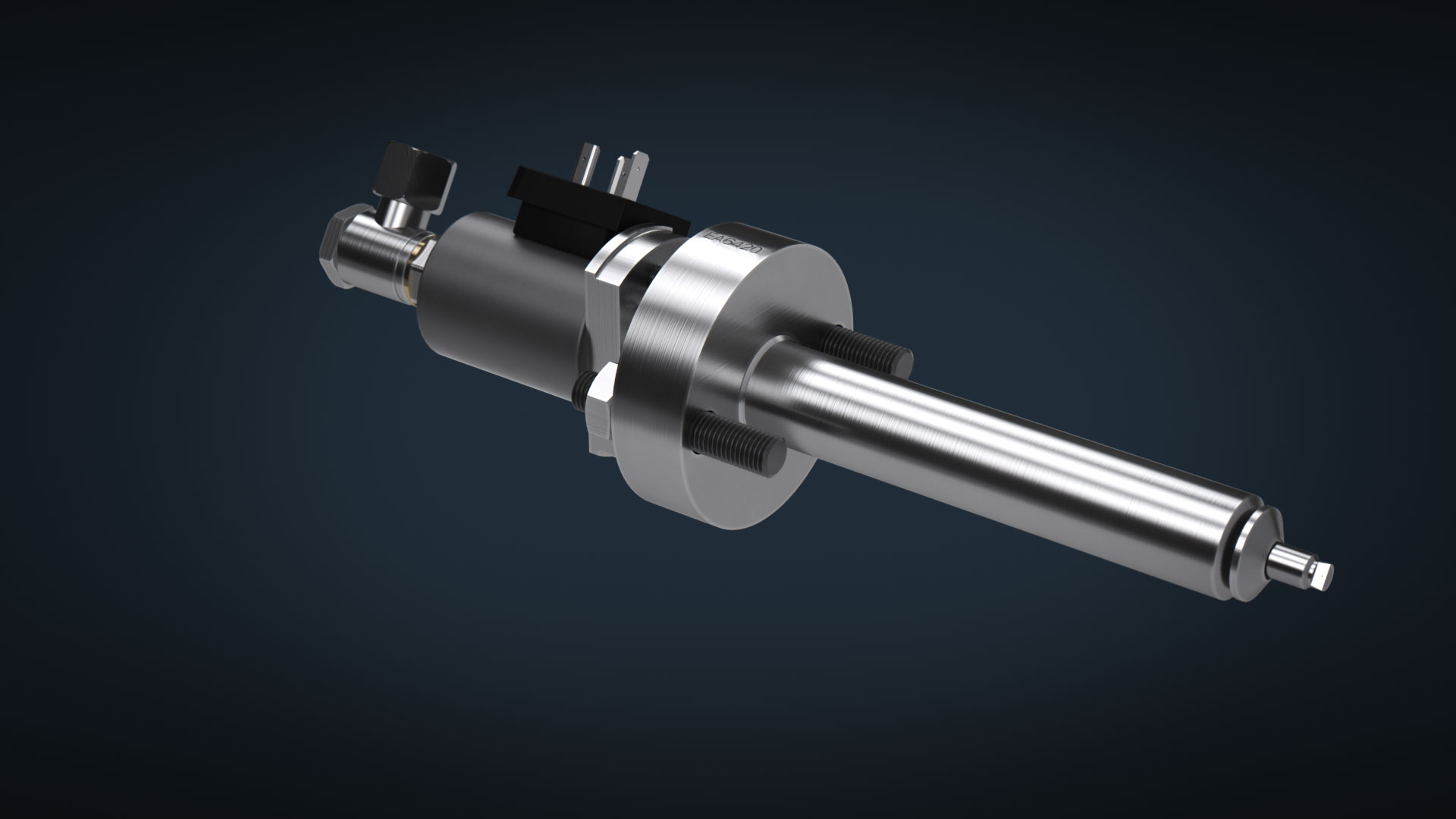

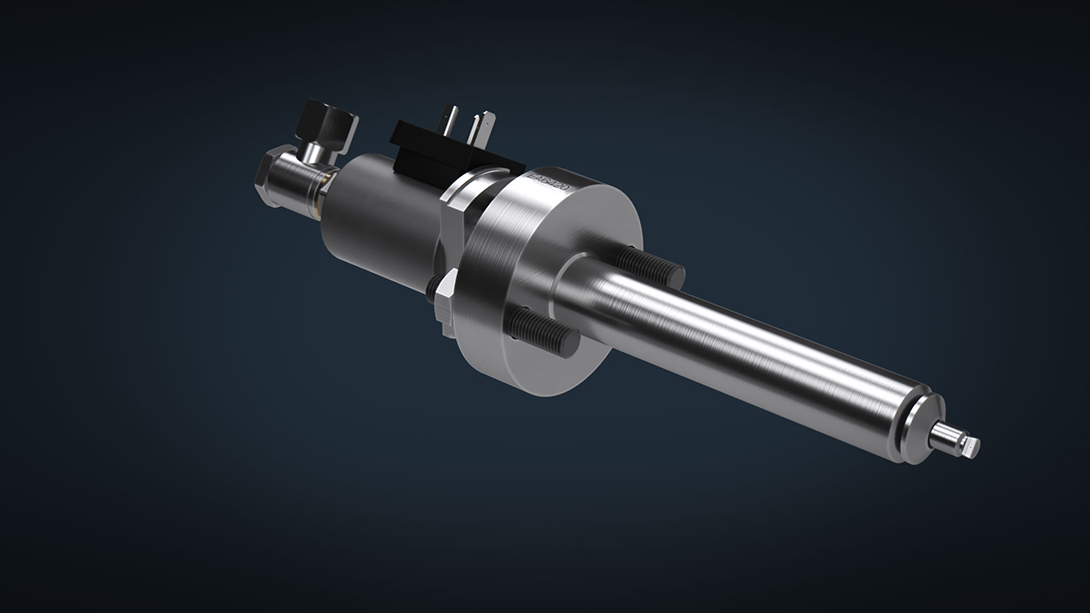

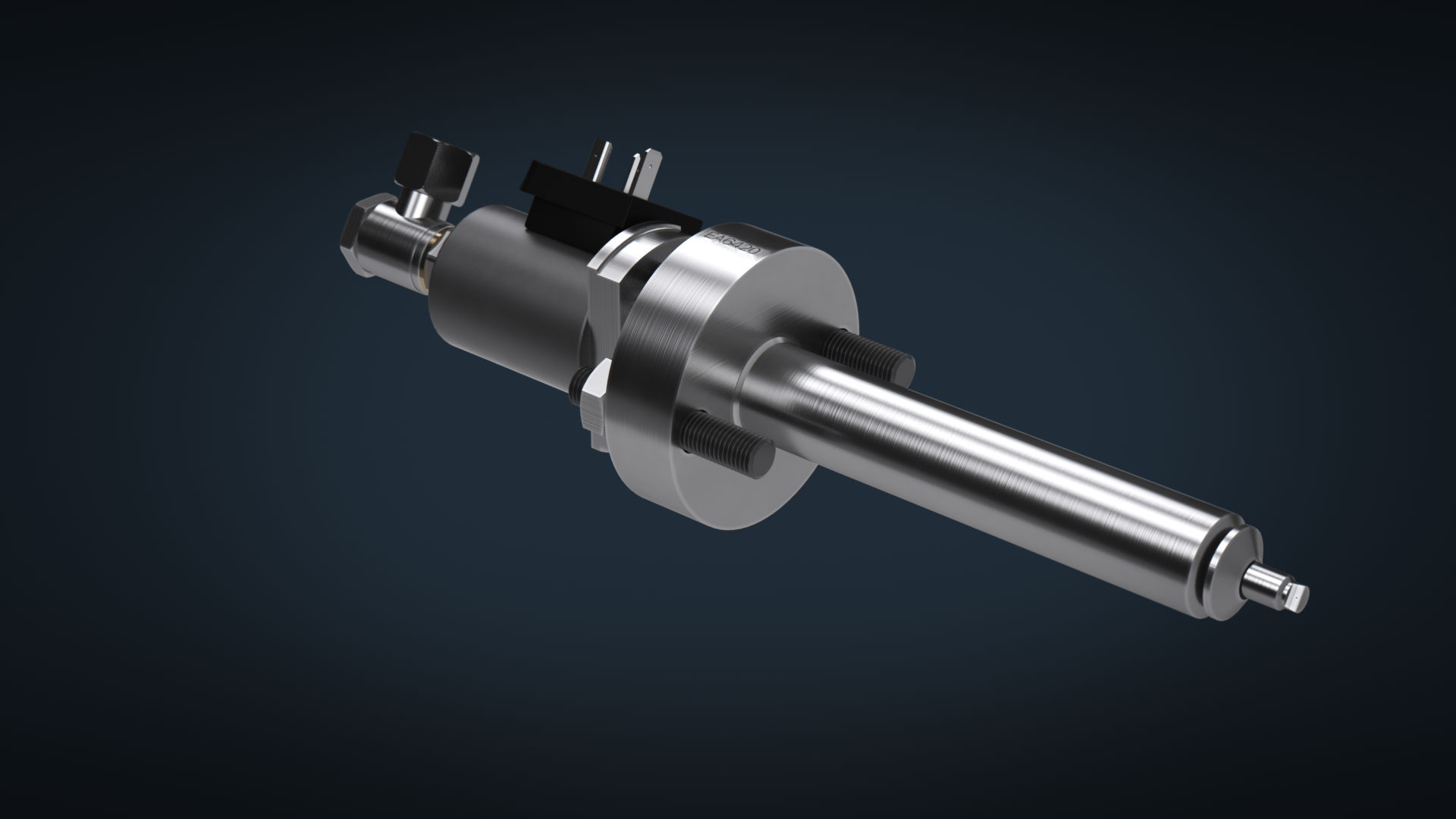

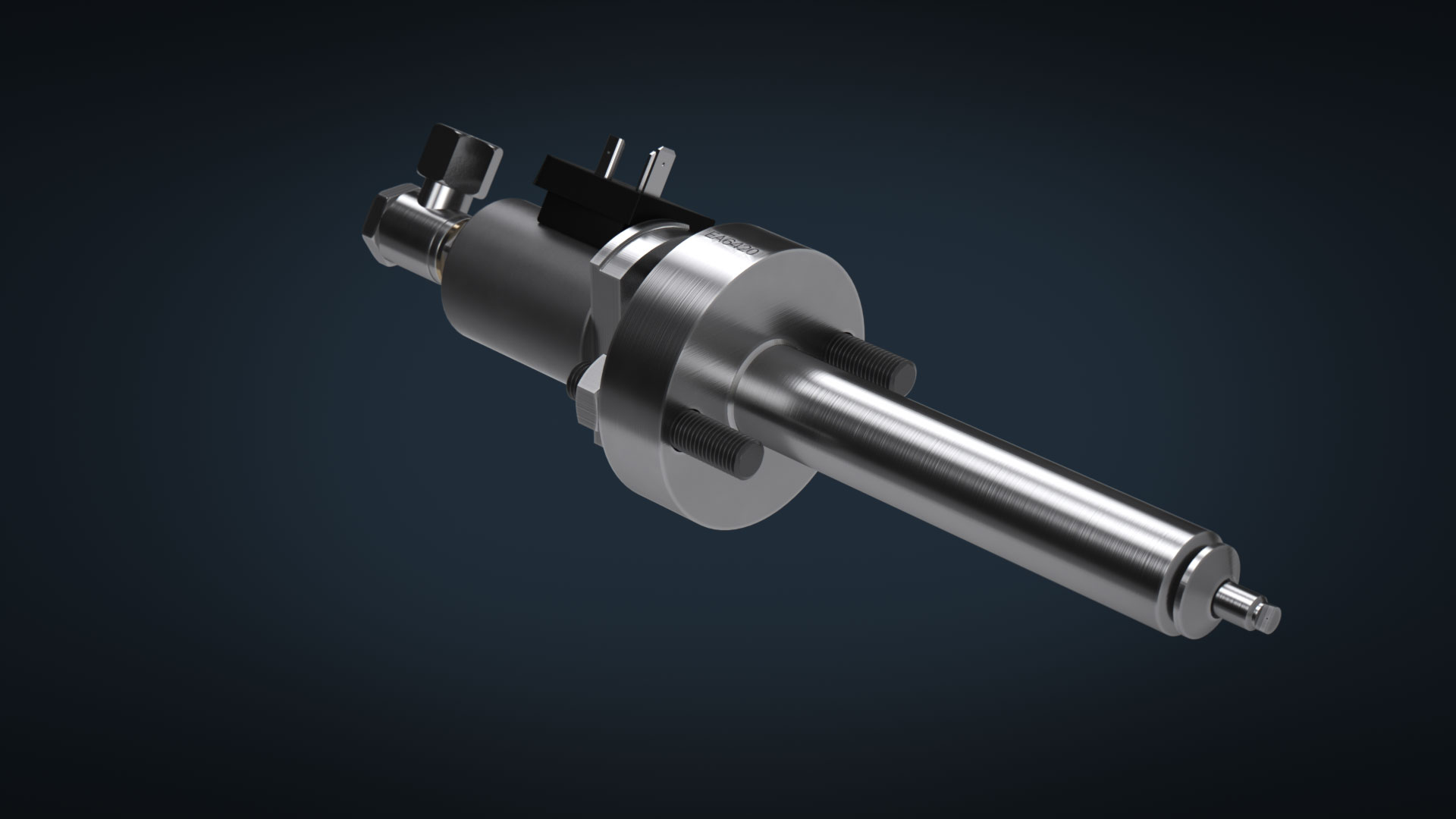

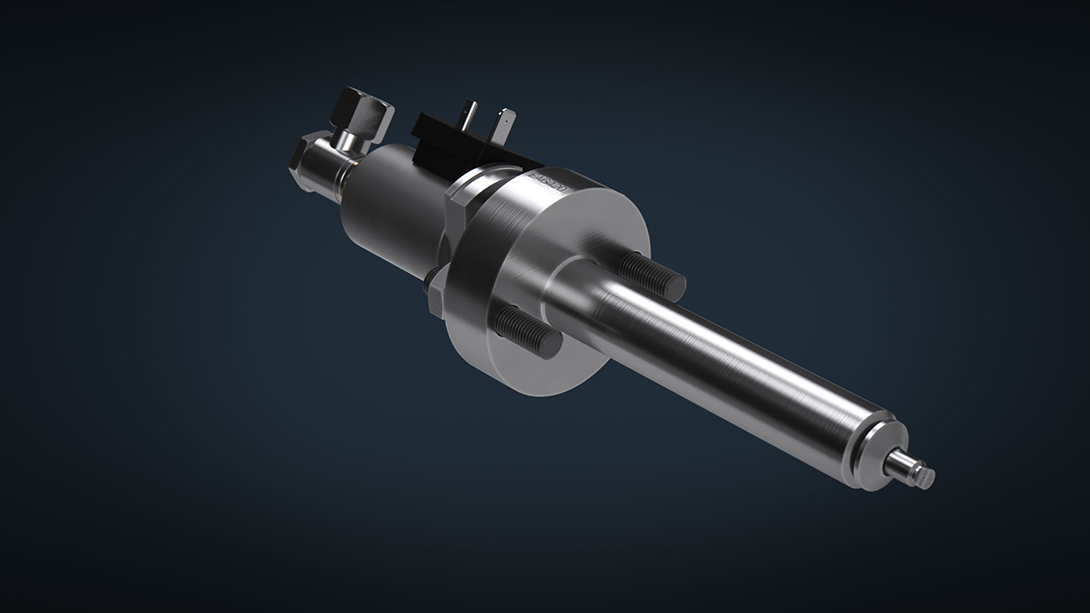

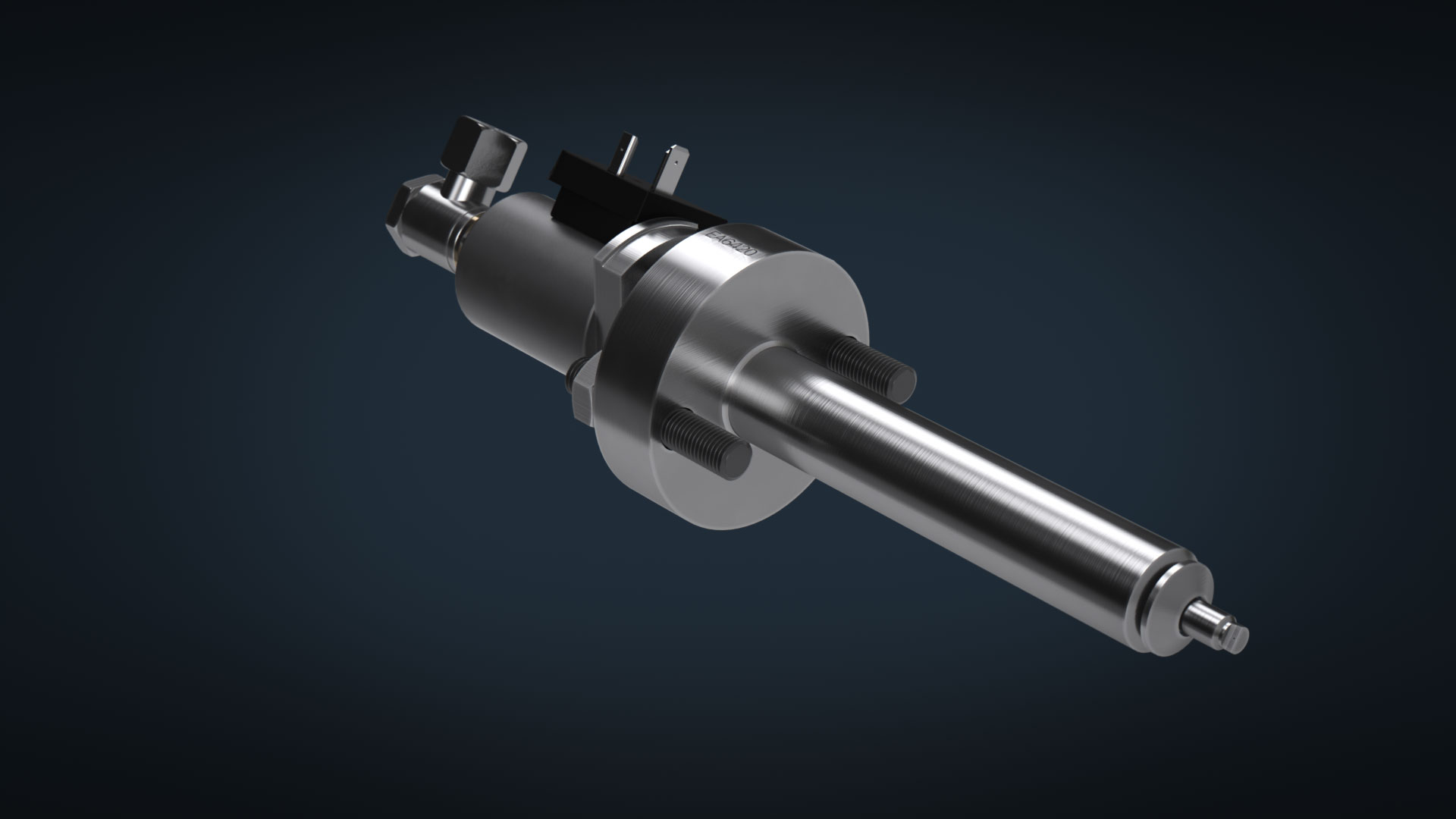

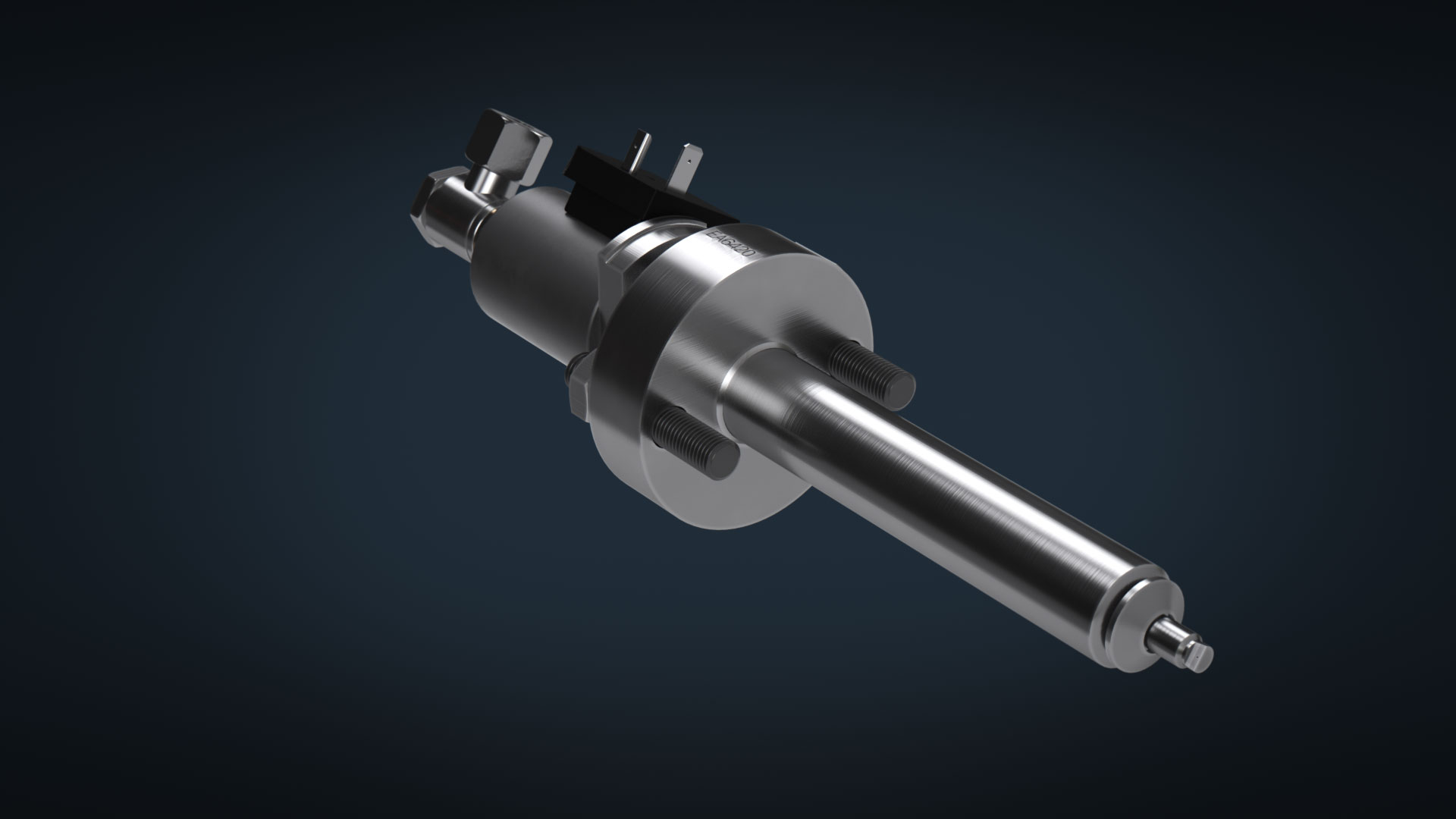

The HJ E-SIP valve is a cylinder lubrication valve, which is electronically controlled – The valve is the heart of the HJ Smartlube 4.0 system. This means the valve can inject any amount of cylinder oil as well as on any crankshaft angle of the engine.

Furthermore, the valve can utilize the “Swirl Injection Principle”, where tiny oil droplets are injected into the centrifugal power of the scavenging air swirl, ensuring optimum distribution of the cylinder oil – as well as injection into the piston ring pack during the compression and combustion stroke.

HJ E-SIP works on all engine types and designs.

- Cope with any future lubrication scenario

- Multiple injections during every engine revolution

- Optimal engine reliability

- Reduced operational costs

- Reduced cylinder oil consumption

- Reduced maintenance of liners, rings & lubrication equipment

- Minimum crew interventions

-

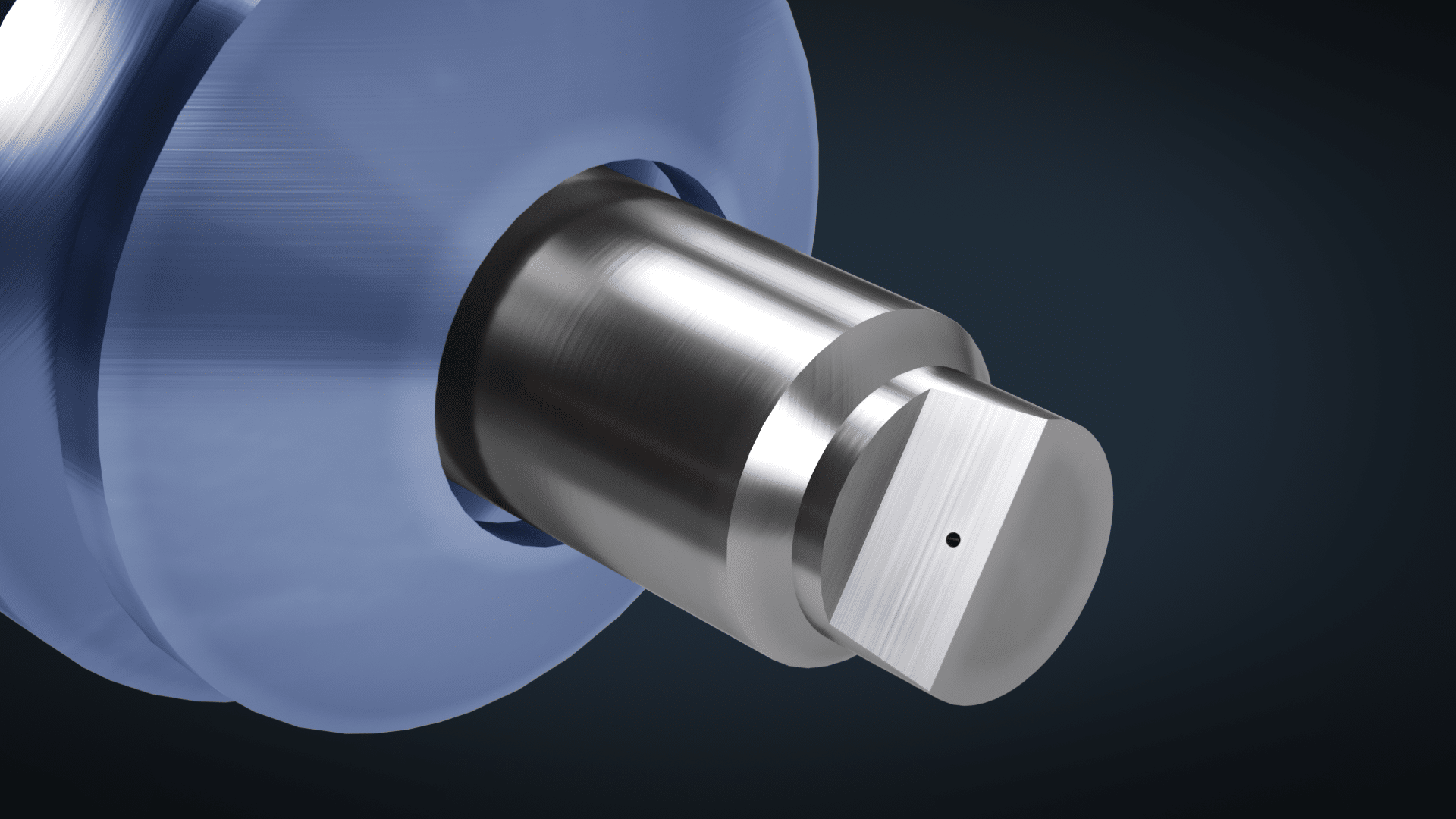

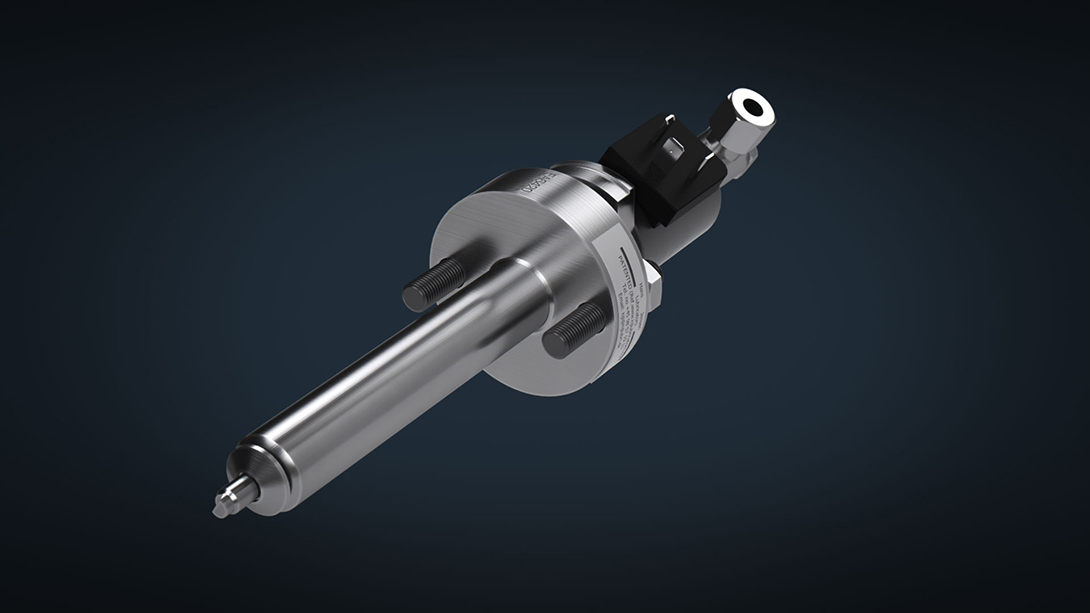

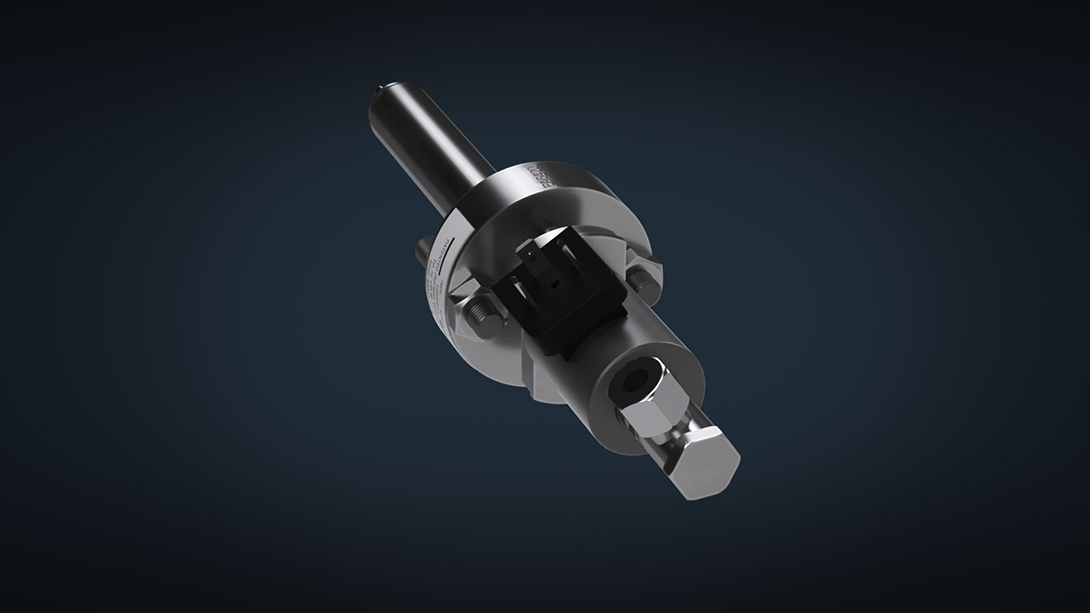

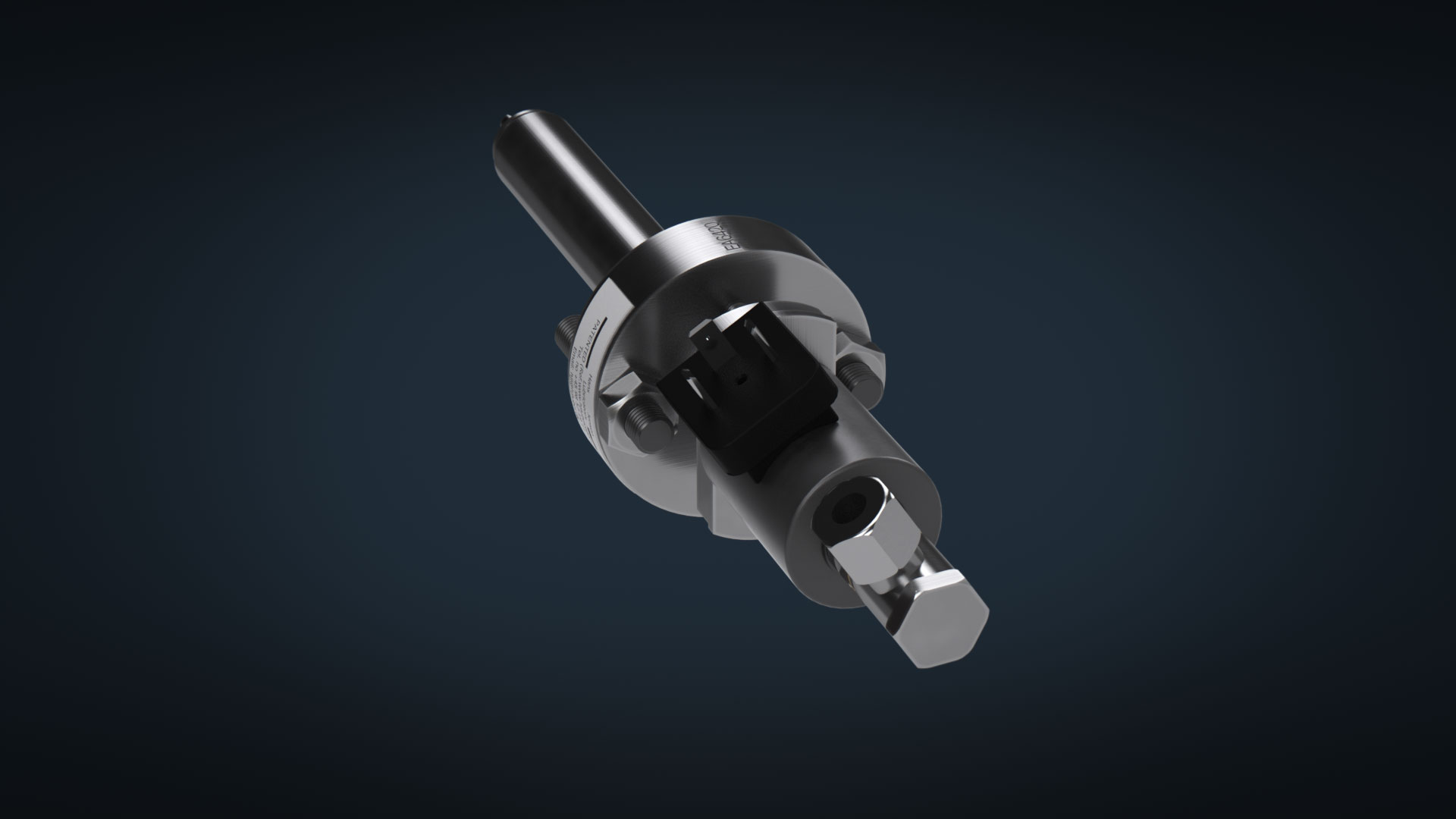

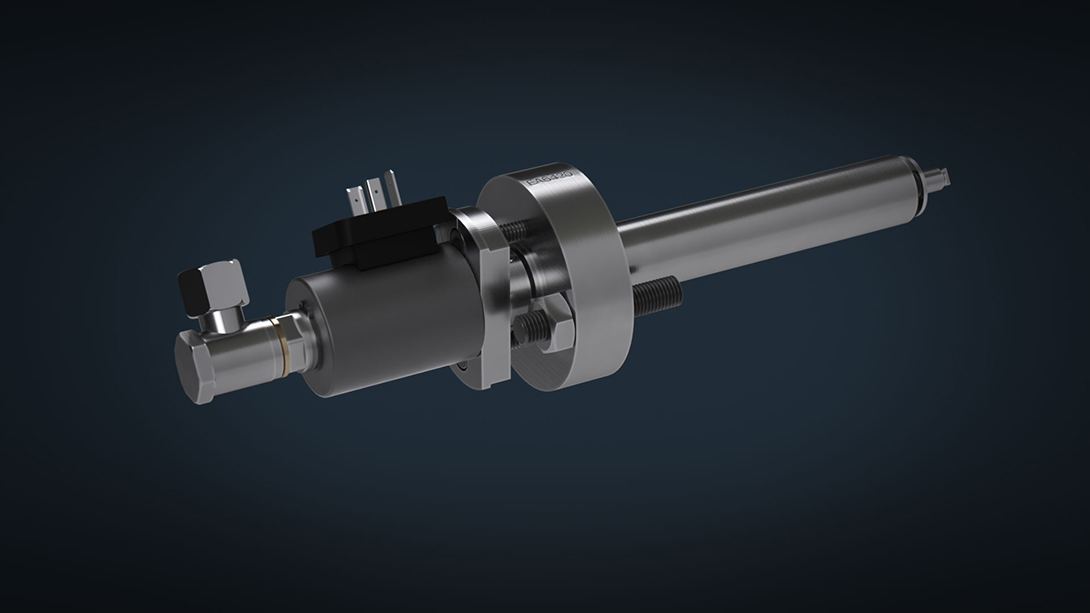

Nozzle

The cylinder oil is sprayed into the cylinder liner through the nozzle opening. By spraying the oil in tiny droplets, into the scavenging air swirl a large surface area of the liner is covered to ensure optimal distribution of the oil. This will ensure proper utilization of the oil.

The nozzle opening is turned at an angle and injects the oil upwards onto the upper part of the liner, where it is most needed – the spray will overlap the next lubrication quill.

-

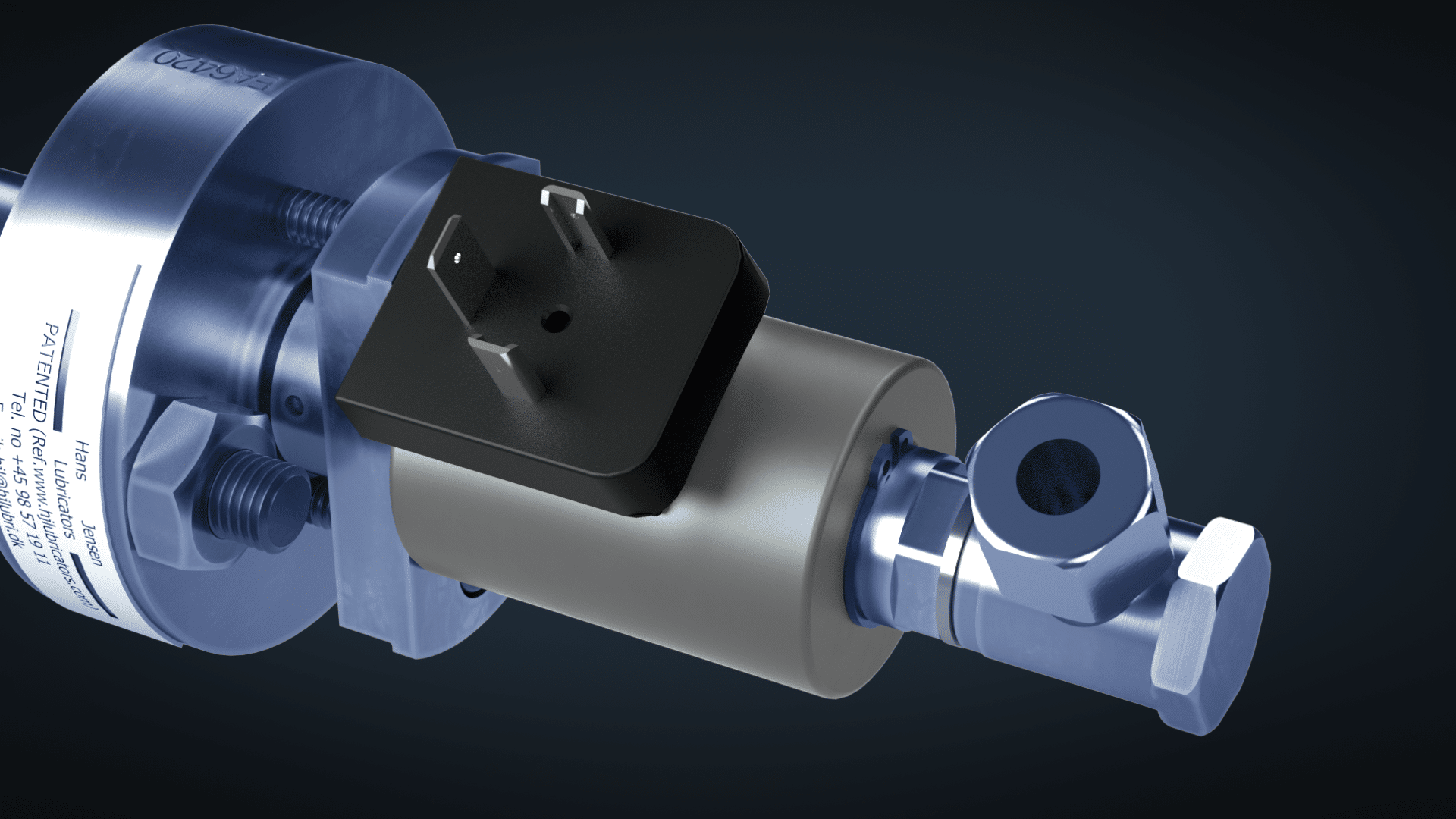

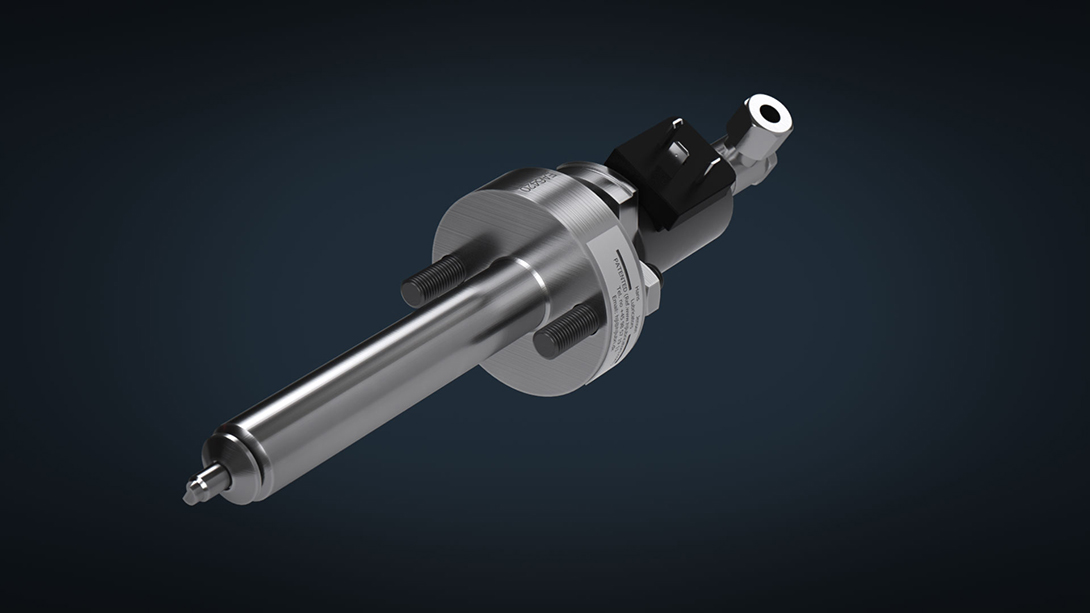

Solenoid

With a common rail delivering high pressure oil, the activation of the valve is done by the electronic solenoid.

The solenoid receives the activation signal from the controller, which determines for how long the valve will be spraying oil.

When the valve closes the excess current in the coil is stored, for the next activation of the valve.

-

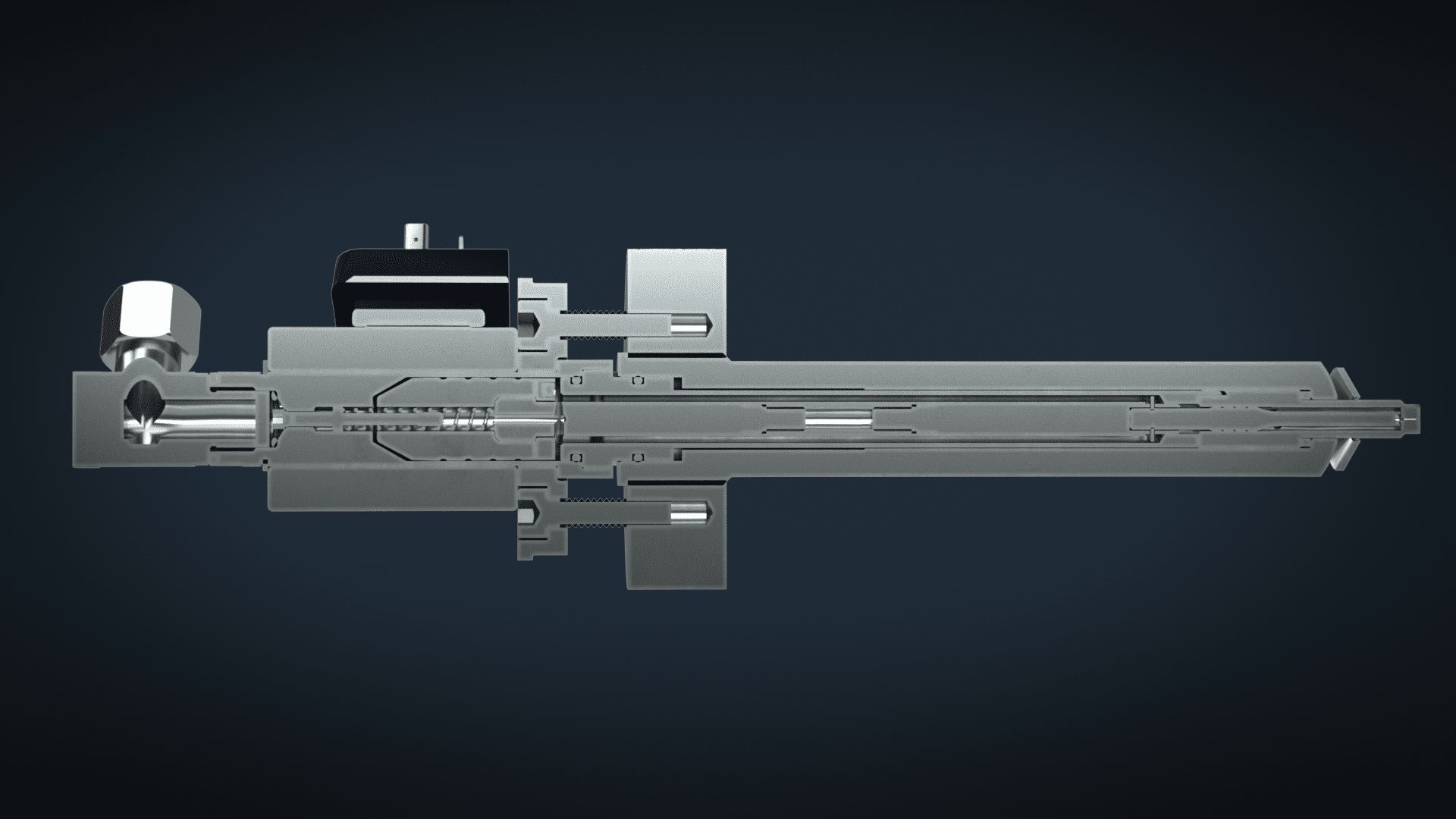

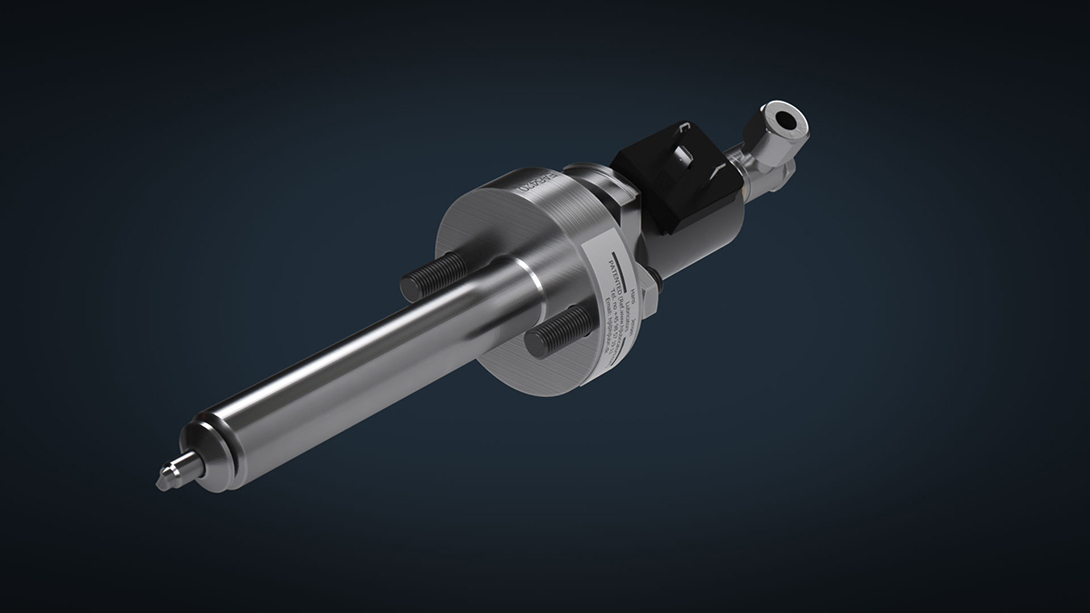

Cross section

Since the valve is activated by the solenoid and not by oil pressure, the possibility of clogged valves has been minimized.

The oil flow is unidirectional and no internal leakages can occur.

The opening time of the valve determines the amount of oil injected into the cylinder.

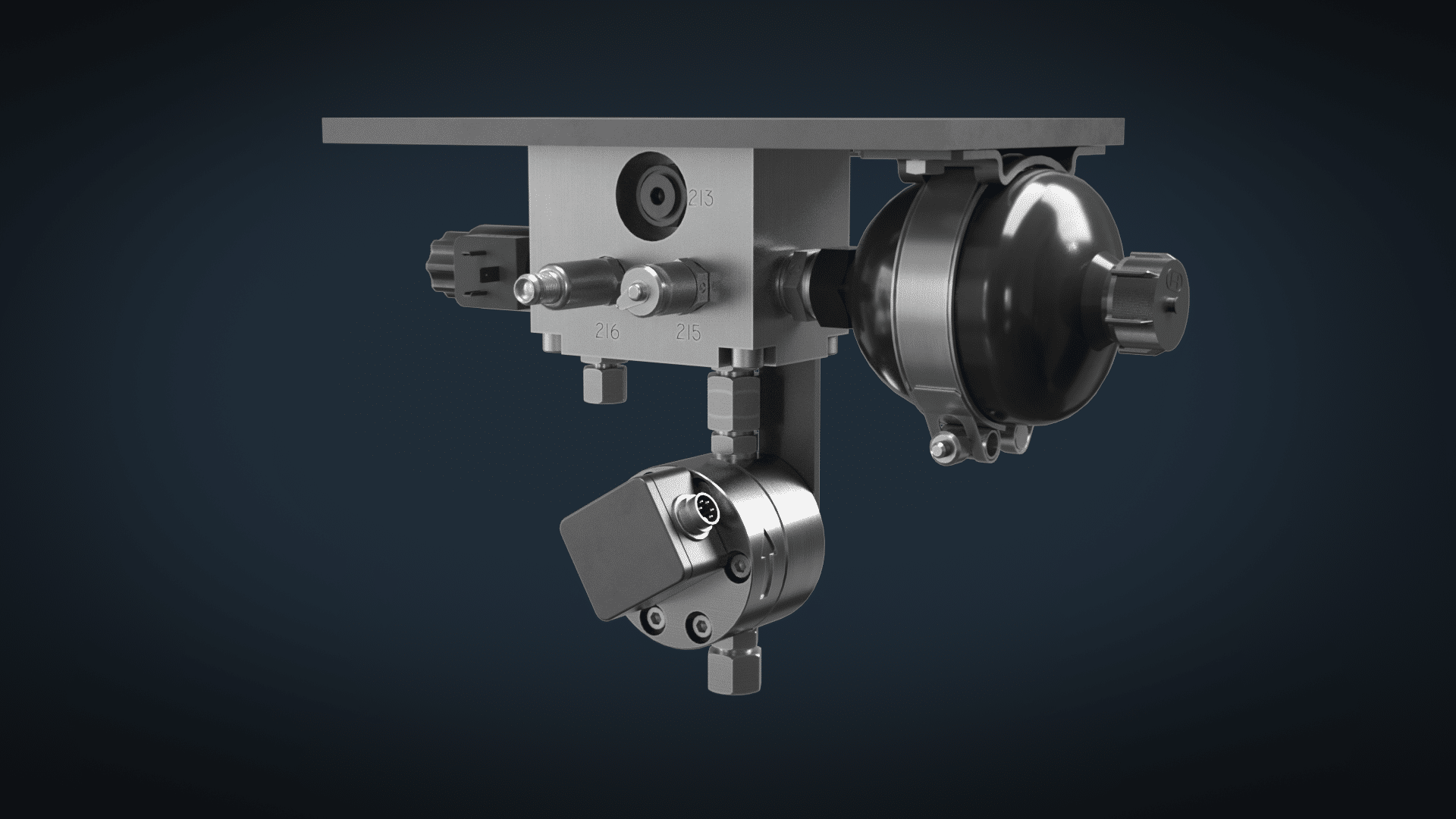

CYLINDER MANIFOLD

The manifold will ensure precise measurement of the feed rate through a feedback loop.

To determine the mass flow of each cylinder, the manifold contains a temperature sensor to determine density as well as a flowmeter to measure the volume passing the manifold.